Temporary filling device for pit pavement for municipal road construction

A technology for municipal roads and filling devices, which is applied in the directions of roads, roads, and road repairs, can solve the problems of high labor intensity of workers, poor sealing effect of feeding openings, inconvenient beating and tamping operations, etc., so as to avoid poor feeding. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

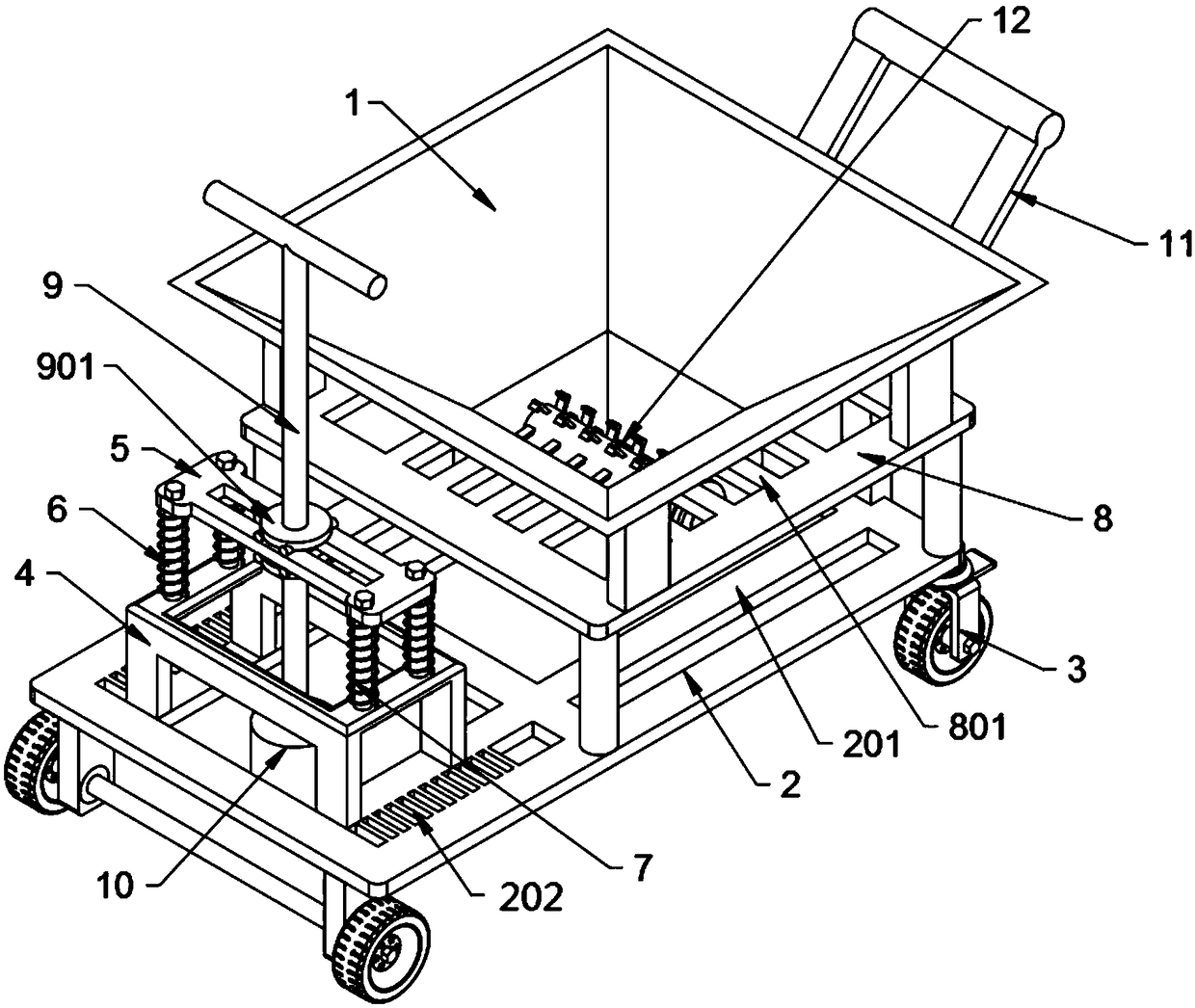

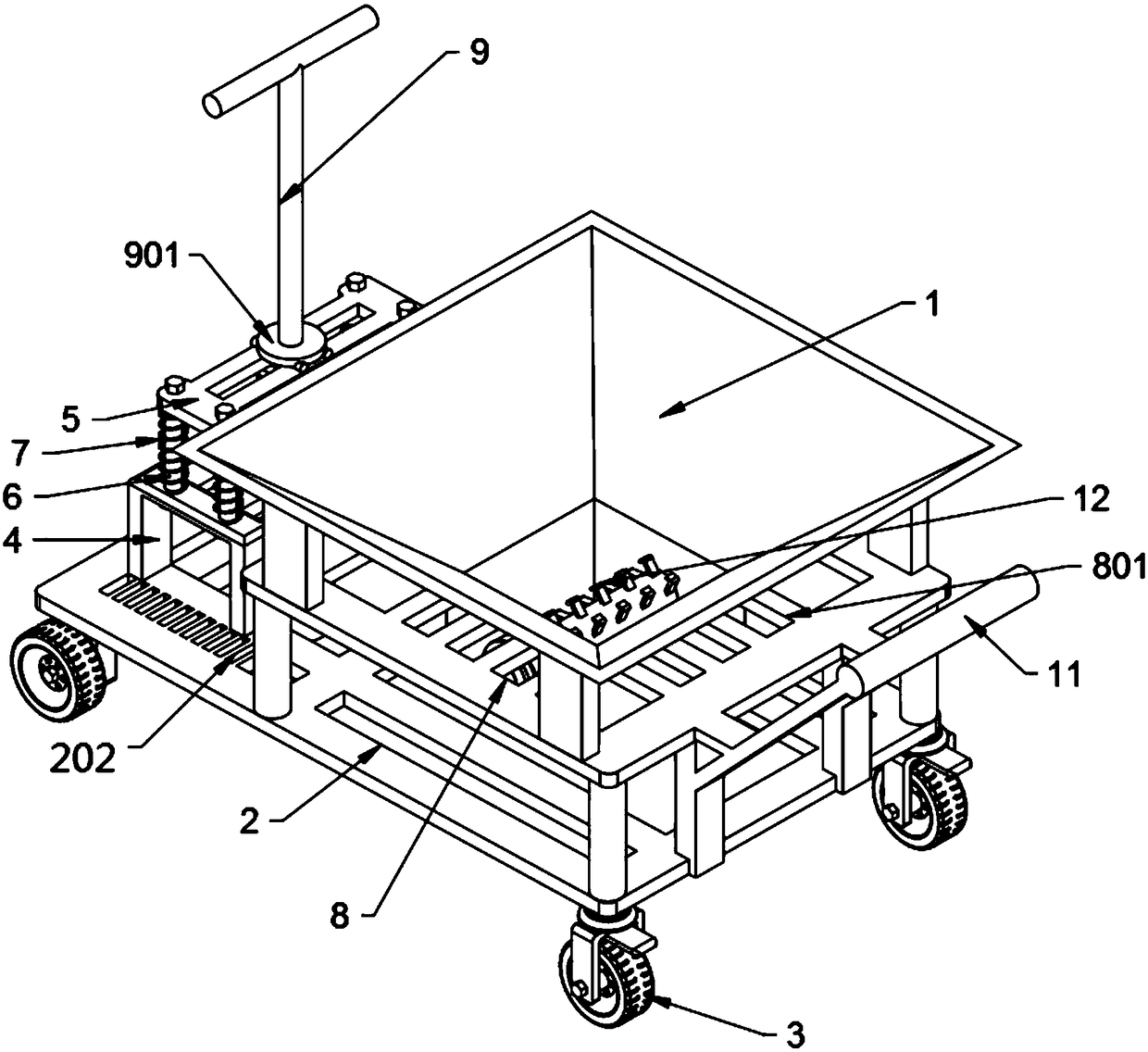

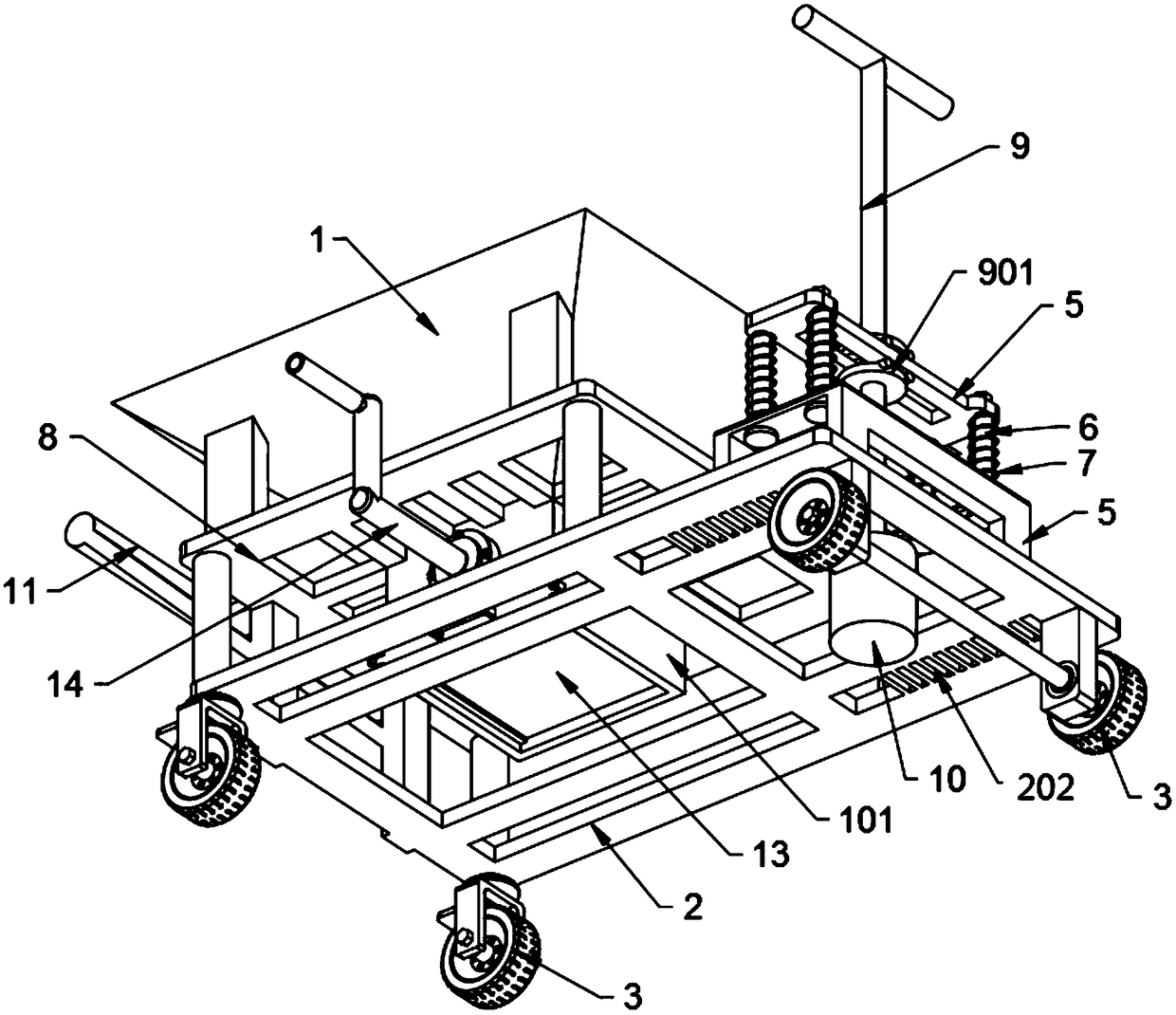

[0038] as attached figure 1 to attach Figure 9 Shown:

[0039] The present invention provides a temporary filling device for potholes and road faces in municipal road construction, which includes a soil bucket 1, a soil leaking square cylinder 101, a bearing sleeve 102, a slideway 103, a base plate frame 2, a frame support plate 201, a connecting pedal 202, and wheels 3 , support frame 4, brace plate 5, sliding strut 6, spring 7, brace frame 8, brace frame plate 801, beating bar 9, circular limit plate 901, pile hammer 10, push rod 11, feeder 12, Baffle plate 13, crank handle 14, spring fixing buckle 15, rotating shaft 16 and rotating square insert rod 161, the described soil bucket 1 is hollowed out inside an inverted quadrangular platform as a whole, and its bottom is welded and suspended to communicate with a square earth leakage cylinder 101 , and the front and rear inner walls of the bottom of the earth leaking square cylinder 101 are symmetrically supported and welded...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com