System and method for controlled expansion valve adjustment

A technology for expansion valves and refrigeration systems, applied in the direction of refrigeration safety arrangements, gas cycle refrigerators, refrigerators, etc., can solve the problems that the flow adjustment device cannot operate normally, and it is difficult to control the pull-down process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

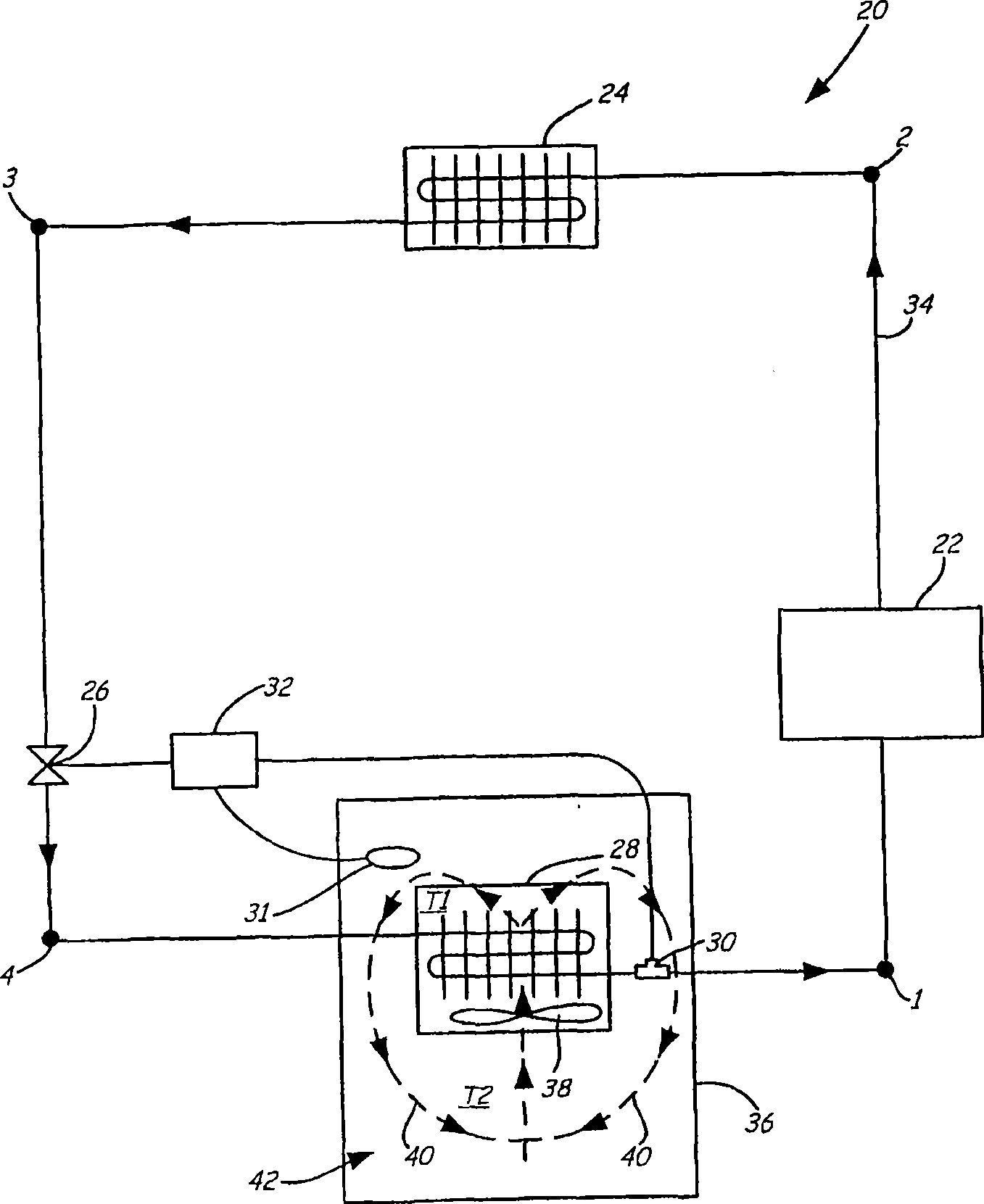

[0012] figure 1 A schematic diagram of a refrigeration system 20 including a compressor 22 , a gas cooler 24 , an expansion valve 26 , an evaporator 28 , an evaporator sensor 30 , an enclosure sensor 31 , and a valve controller 32 is shown. Compressor 22 may comprise any type of compressor including (but not limited to): reciprocating, scroll, screw, rotary vane, vertical vane, variable speed, hermetic, and open drive compressors.

[0013] The refrigeration system 20 is suitable for any occasion requiring a cold source, such as in temperature control units of buildings and automobiles. However, the refrigeration system 20 will be described generically in terms of "enclosures" that require cooling. For example, this "enclosure" might be an office area in a building, or a food storage area in a refrigerated food transport vehicle.

[0014] Such as figure 1 As shown, the refrigerant path 34 is formed by connecting various components in the refrigeration system 20 . The refrig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com