Motor stator and mold motor

A motor and stator technology, applied in the field of molded motors, can solve problems such as trouble

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

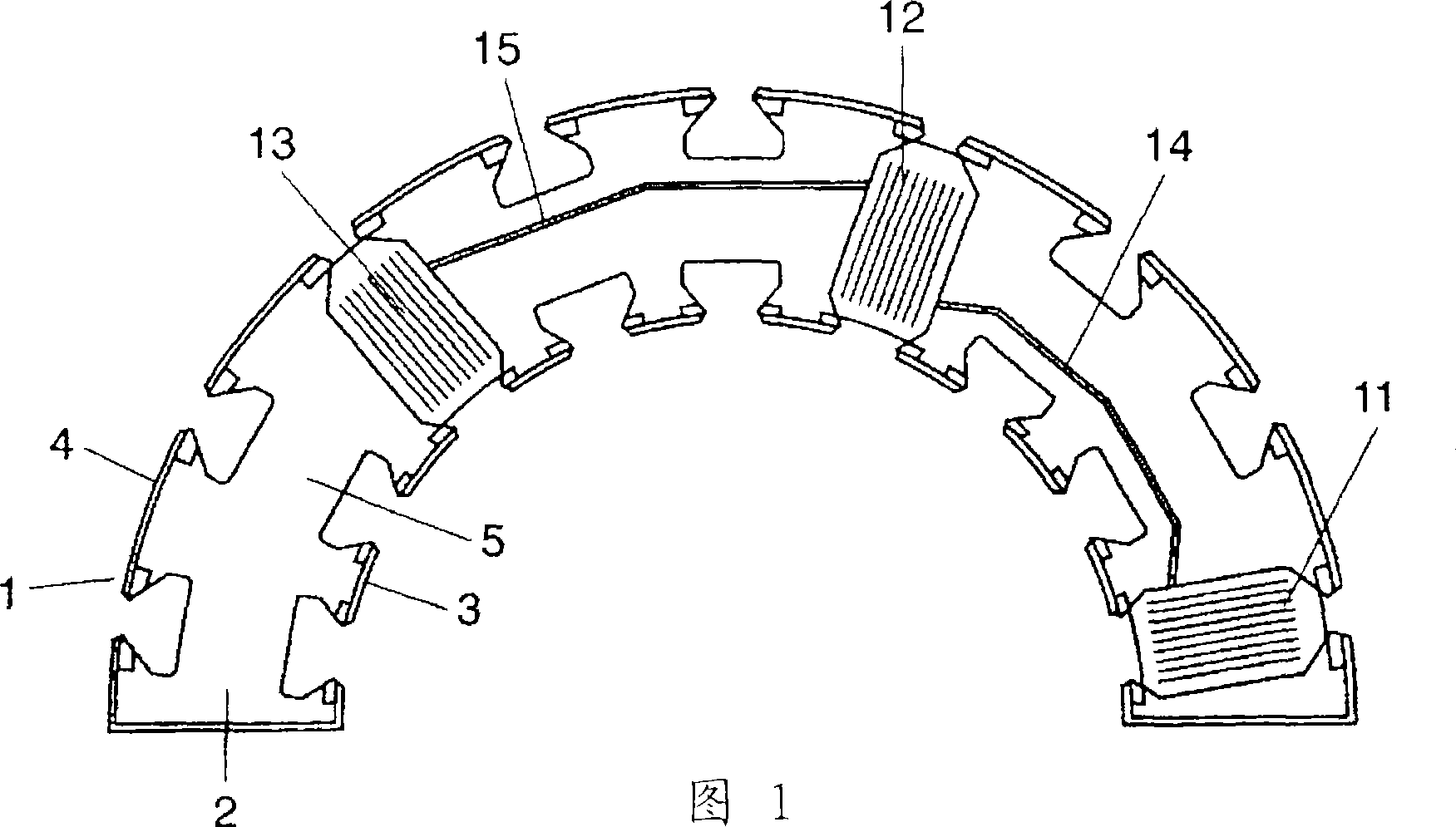

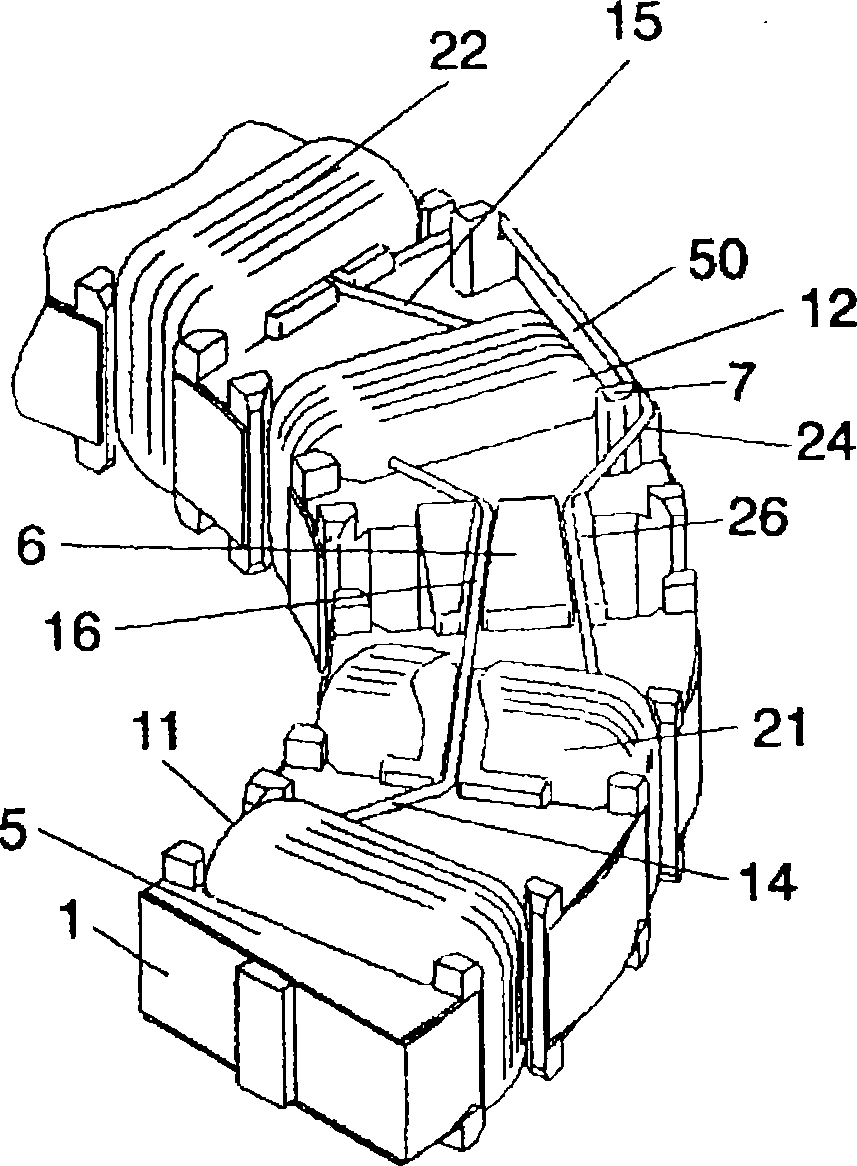

[0024] Embodiments of the present invention will be described below using the drawings.

[0025] As shown in FIG. 1 , a divided stator core (hereinafter referred to as “stator core”) 1 which divides an annular stator core into half has inner teeth 3 and outer teeth 4 on both sides of a yoke 2 . The insulating cover 5 covers the stator core 1 . Hereinafter, a procedure for sequentially winding the coils of the first phase, the second phase, and the third phase of the three-phase winding into the slots between the teeth of the stator core 1 in a circular manner will be described.

[0026] First, as shown in FIG. 1 , the coils 11 , 12 , 13 of the first phase are sequentially wound on the stator core 1 via the connecting wires 14 , 15 between the connecting coils.

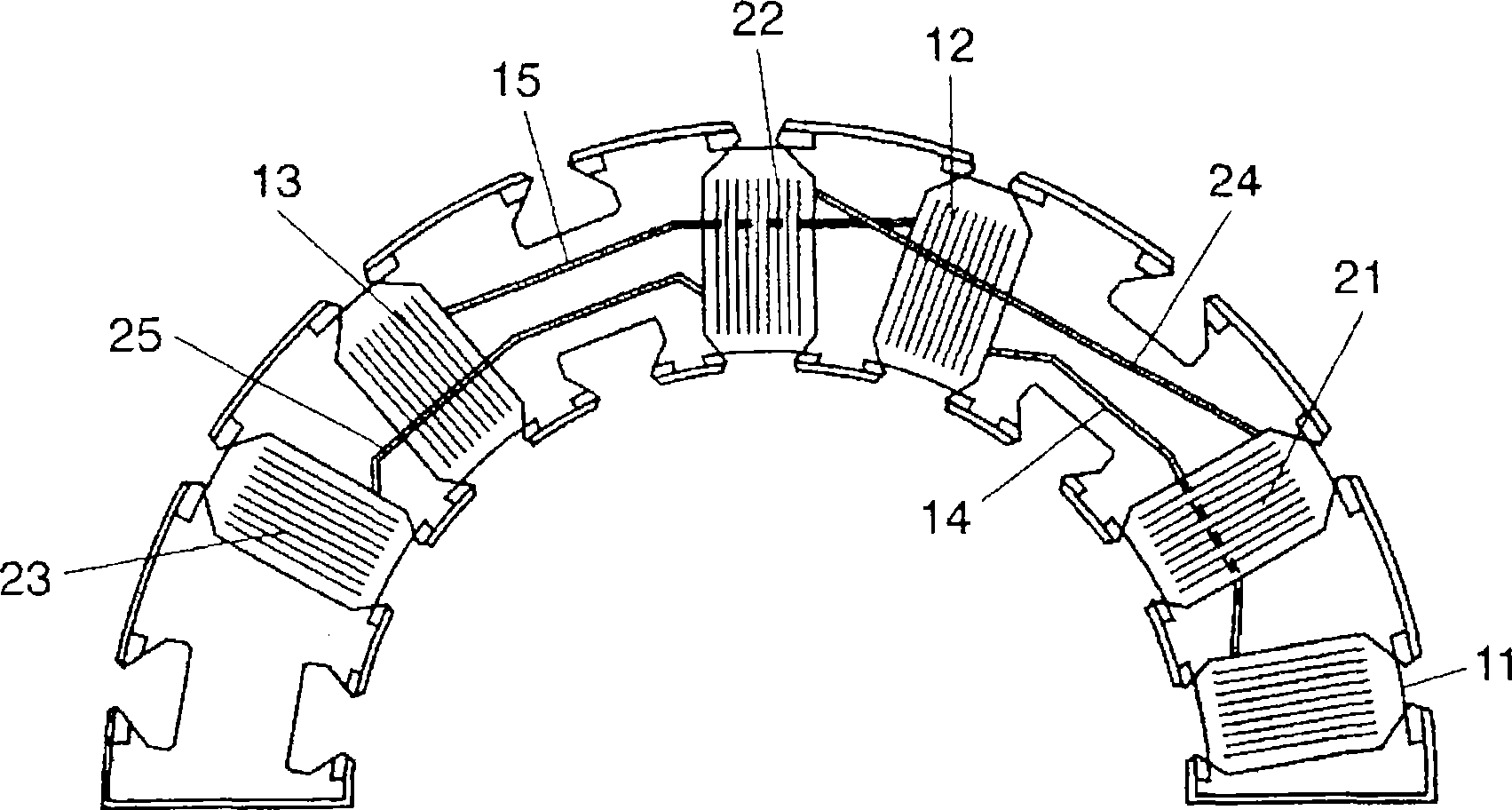

[0027] Next, if figure 2 As shown, coils 21 , 22 , 23 of the second phase are sequentially wound on stator core 1 via connection wires 24 , 25 . The connecting line 24 spans over the coil 12 of the first phase. Li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com