Water-cooling injection nozzle structure for plug-in hot box

A hot core box and plug-in technology, which is used in casting and molding equipment, metal processing equipment, molding machines, etc., can solve the problems of reducing production efficiency, wasting raw materials, and easy curing of coated sand, and achieve the effect of improving production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

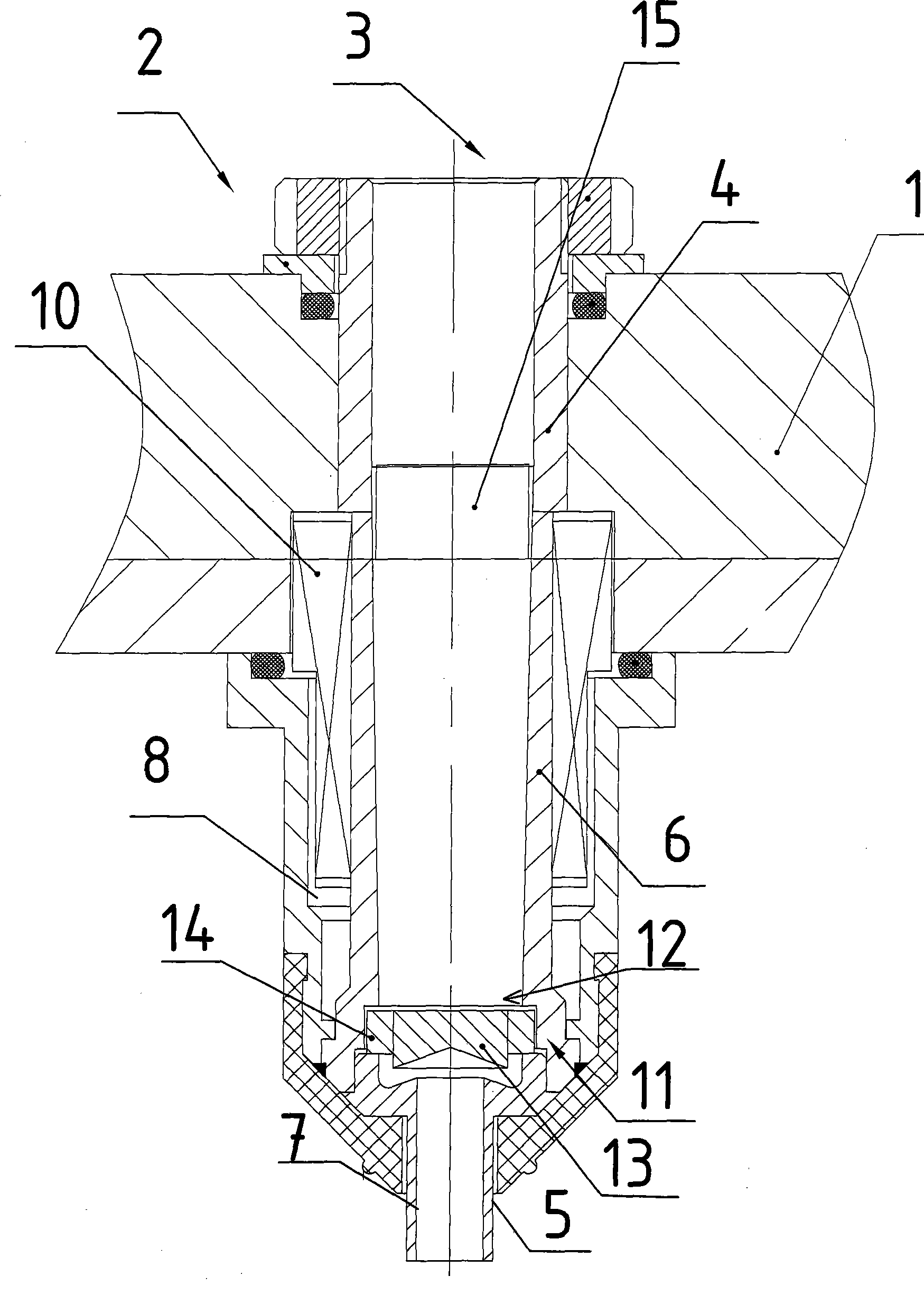

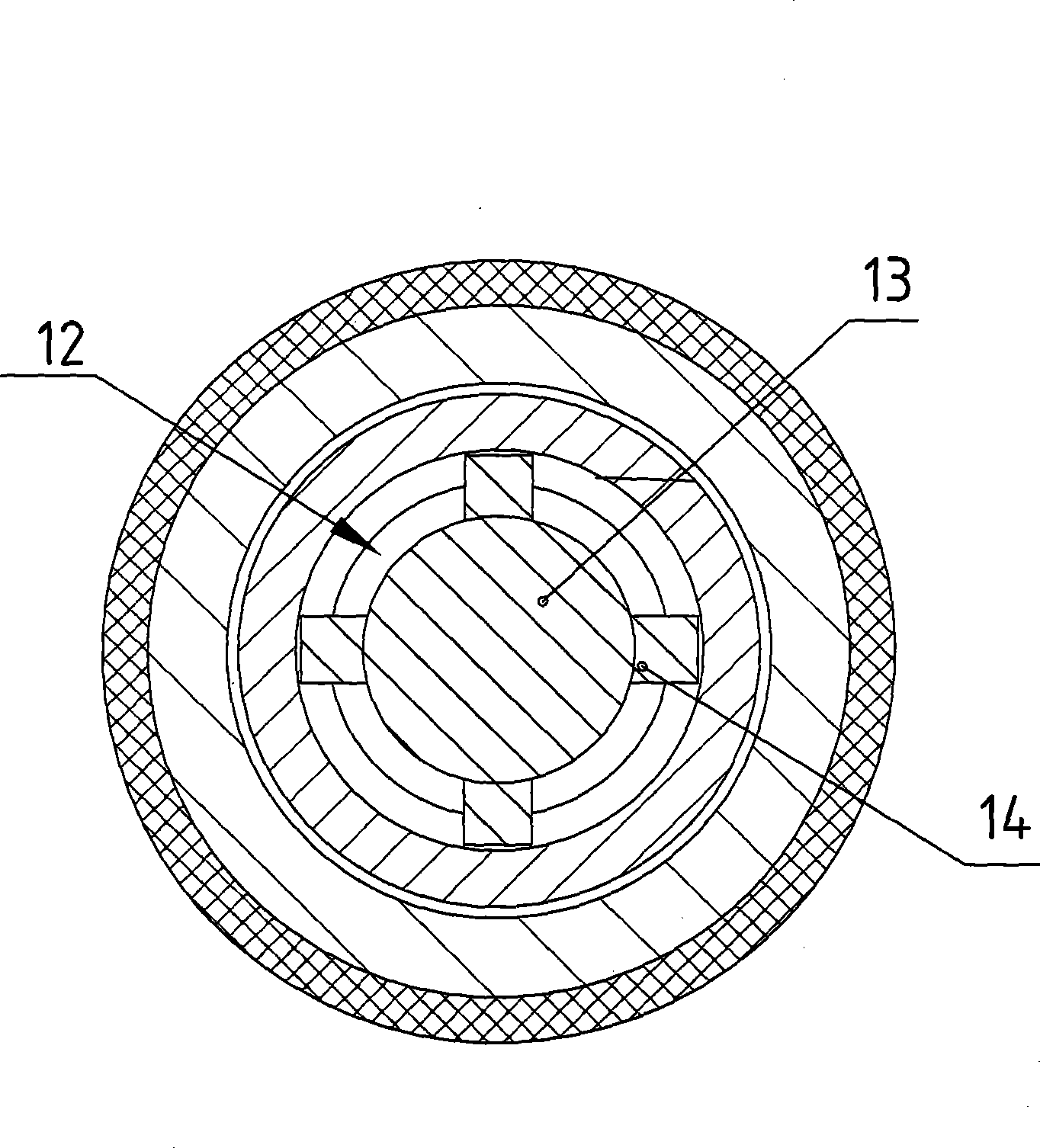

[0011] The specific structure and working principle of the present invention will be further described below in conjunction with the accompanying drawings.

[0012] See attached figure 1 - As shown in -2, a plug-in hot core box water-cooled nozzle structure is installed on the sand shooting board 1, the structure includes a nozzle 2 with a sand shooting channel 3, and the nozzle 2 includes a nozzle body 4 and a nozzle body 4. The nozzle head 5 installed on the lower end of the nozzle body 4, the sand-shooting passage 3 includes a body passage 6 in the nozzle body 4 and a head passage 7 in the nozzle head 5. When sand is shot, the nozzle head 2 Insert into the upper core box and inject the core sand into the cavity. The temperature in the cavity is generally 200-400°C. The high temperature loose sand is used to solidify to form a sand core. Since there is loose sand in the nozzle 2, the environment of the core box The high temperature will also solidify part of the dispersed s...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap