Prepositive pin roller-roller mixed ramie stretch-breaking apparatus

A needle-roller and hybrid technology, which is applied in the field of front needle-roller-roller hybrid ramie drawing-cutting spinning equipment, can solve the problem that the problem of drawing and slivering has not been well resolved, reducing the number of spun threads, and ramie refined and dried hemp. The problems of looseness and unsatisfactory degree of separation can achieve the effect of eliminating ultra-long fibers, reducing multi-filaments, and avoiding violent effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

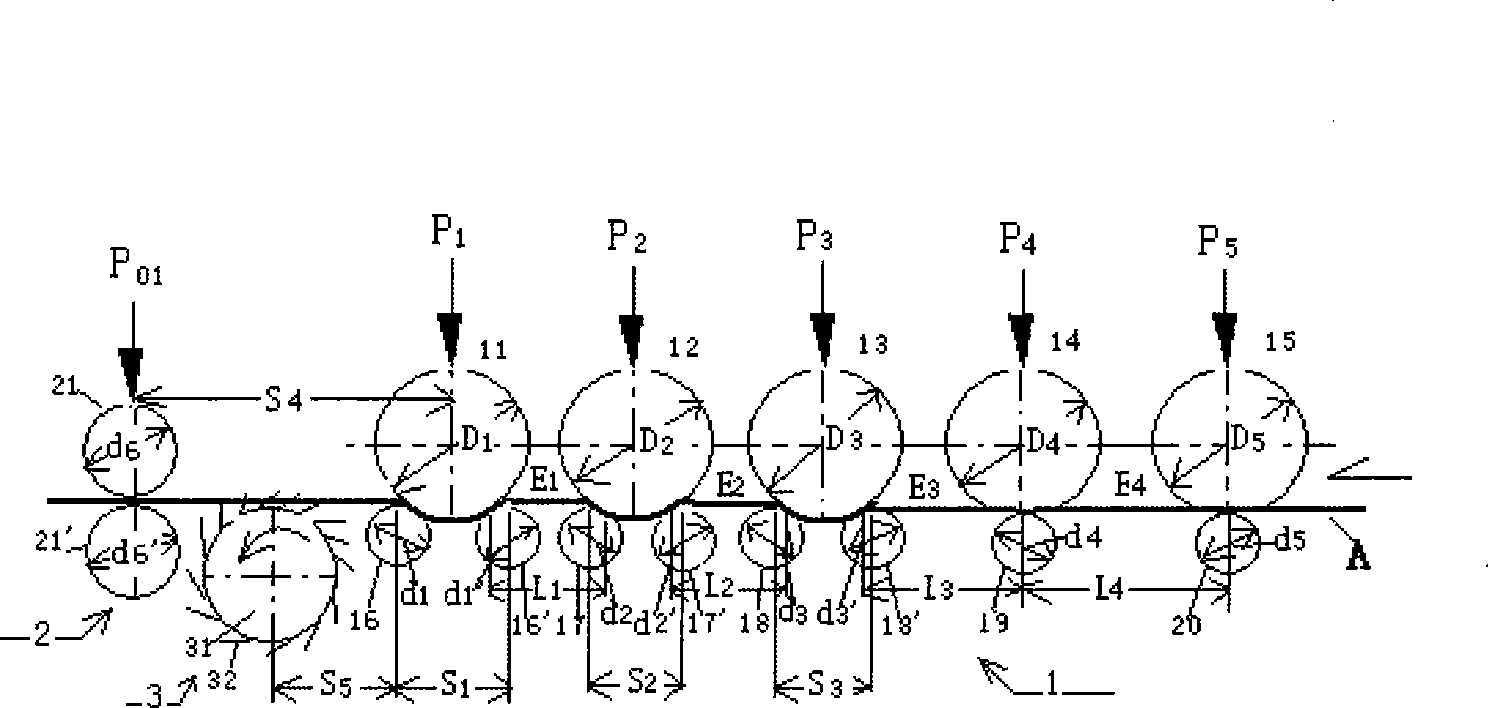

[0019] like figure 1 As shown, it is a kind of pre-needle roller mixed type ramie stretch-cutting spinning equipment of the present invention, which is composed of a roller-type stretch-cut device 1, a pull-out roller device 2 and a needle roller device 3 respectively fixed on the frame, The needle roller device 3 is arranged between the roller type stretching device 1 and the take-off roller device 2 .

[0020] Described roller type stretching device 1 comprises the first top roller 11, the second top roller 12, the 3rd top roller 13, the 4th top roller 14 and the 5th top roller 15, the first top roller 11, the second top roller 12 and the third top roller 13 are engaged with the first pair of rollers 16, 16', the second pair of rollers 17, 17' and the third pair of rollers 18, 18' respectively, the fourth top roller 14 and the fifth top roller 15 are respectively Engaging with the fourth roller 19 and the fifth roller 20, wherein the diameter D of the first top roller 11 1...

Embodiment 2

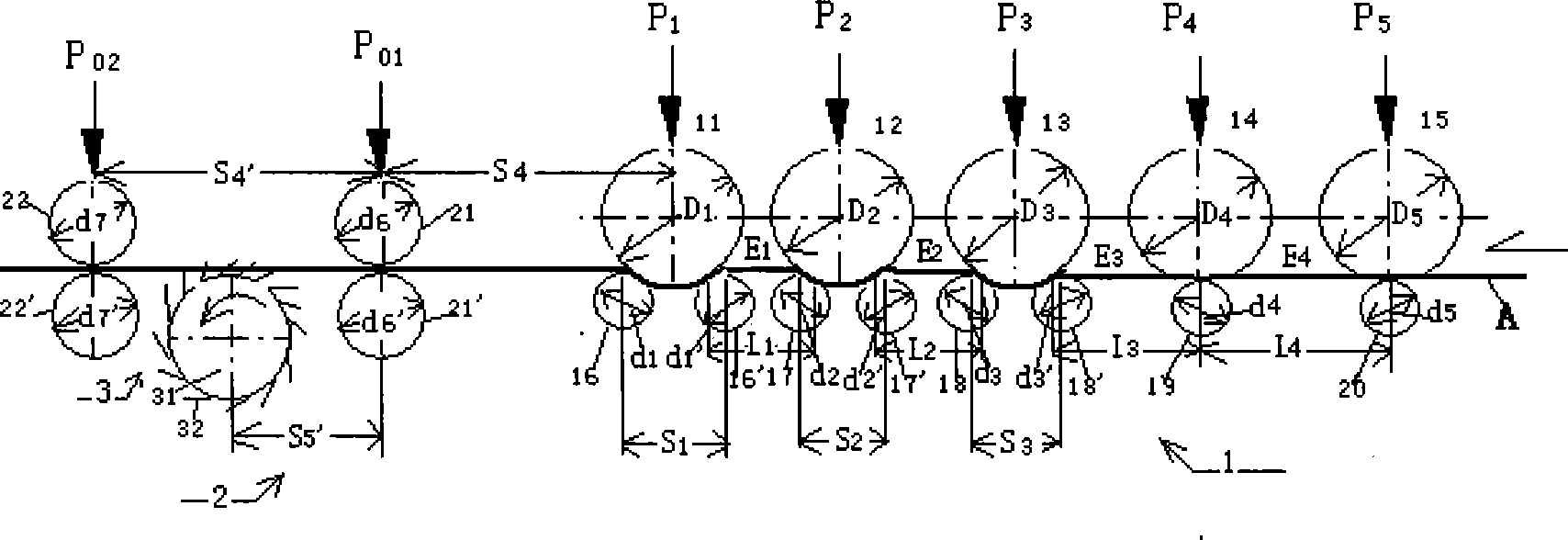

[0025] like figure 2 As shown, it is another pre-needle-roller hybrid ramie stretch-cut spinning equipment of the present invention, which consists of a roller-type stretch-cut device 1, a pull-out roller device 2 and a needle roller device 3 respectively fixed on the frame. , The needle roller device 3 is located between the roller type stretching device 1 and the take-off roller device 2 .

[0026] Described roller type stretching device 1 comprises the first top roller 11, the second top roller 12, the 3rd top roller 13, the 4th top roller 14 and the 5th top roller 15, the first top roller 11, the second top roller 12 and the third top roller 13 are engaged with the first pair of rollers 16, 16', the second pair of rollers 17, 17' and the third pair of rollers 18, 18' respectively, the fourth top roller 14 and the fifth top roller 15 are respectively Engaging with the fourth roller 19 and the fifth roller 20, wherein the diameter D of the first top roller 11 1 , the diam...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Average length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com