Roller needle plate composite stretch breaking and spinning equipment for ramee

A hybrid, roller-needle technology, applied in drafting equipment, spinning machines, textiles and papermaking, etc., can solve problems such as the rapid increase of hemp grains and the difficulty of eliminating ultra-long fibers, so as to eliminate ultra-long fibers, reduce damage, Avoid drastic effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

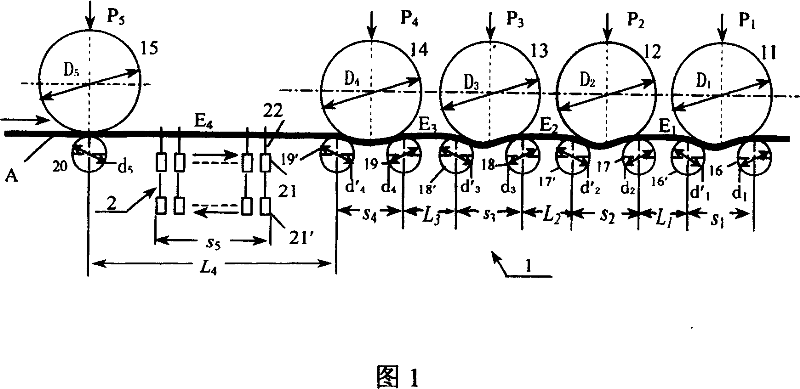

Method used

Image

Examples

Embodiment

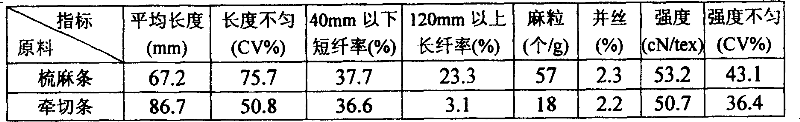

[0023] The ramie refined hemp produced in Hunan is adopted, and its properties are shown in Table 1:

[0024] Table 1 Performance indicators of refined hemp

[0025] average length

[0026] After adopting the roller needle-plate mixed type ramie stretch-cutting spinning equipment of the present invention to above-mentioned lean hemp raw material to process, the quality performance index of its semi-finished product and finished product is as shown in table 2 and table 3:

[0027] Table 2 Comparison of quality indicators between stretch-cut sliver and carded hemp sliver (stretch-cut distance is 110mm)

[0028] As can be seen from Table 2, the length uniformity of the fibers after stretch cutting is significantly improved, especially the content of ultra-long fibers above 120mm is significantly reduced, and the hemp grains in the fiber strips are greatly reduced than those in the carded hemp strips; although the strength is reduced, However, since the weaker fibers ar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com