Safe bearing ball installing system for feeding balls from bottom to top

A safe, bearing technology, applied in bearing components, shafts and bearings, mechanical equipment, etc., can solve the problems affecting the bearing ball loading effect and overall quality, unsatisfactory economy and practicability, affecting the surface finish of the ball, etc. Highlight the advanced technology, remarkable economy, and ensure the effect of assembly quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and typical embodiments.

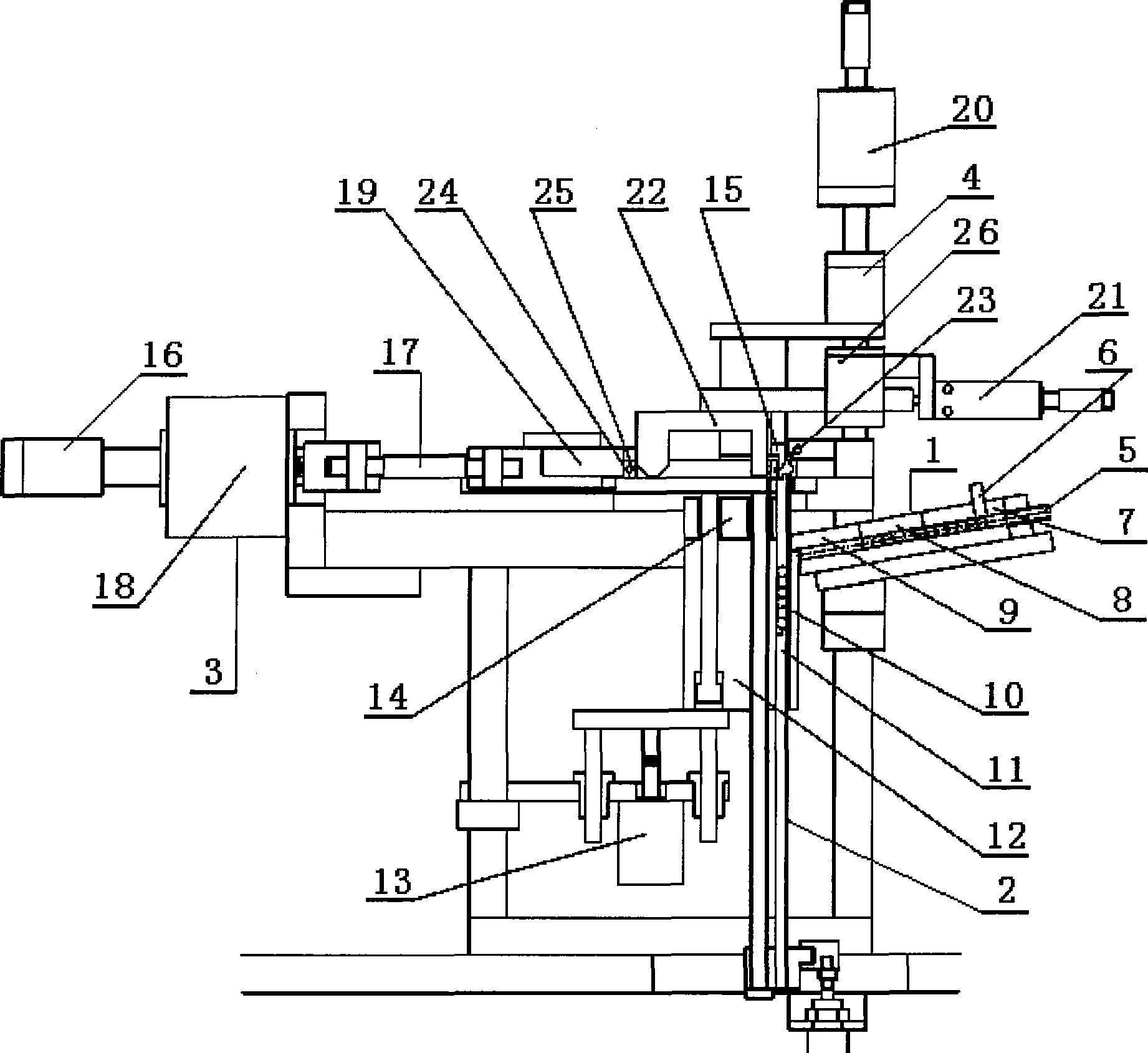

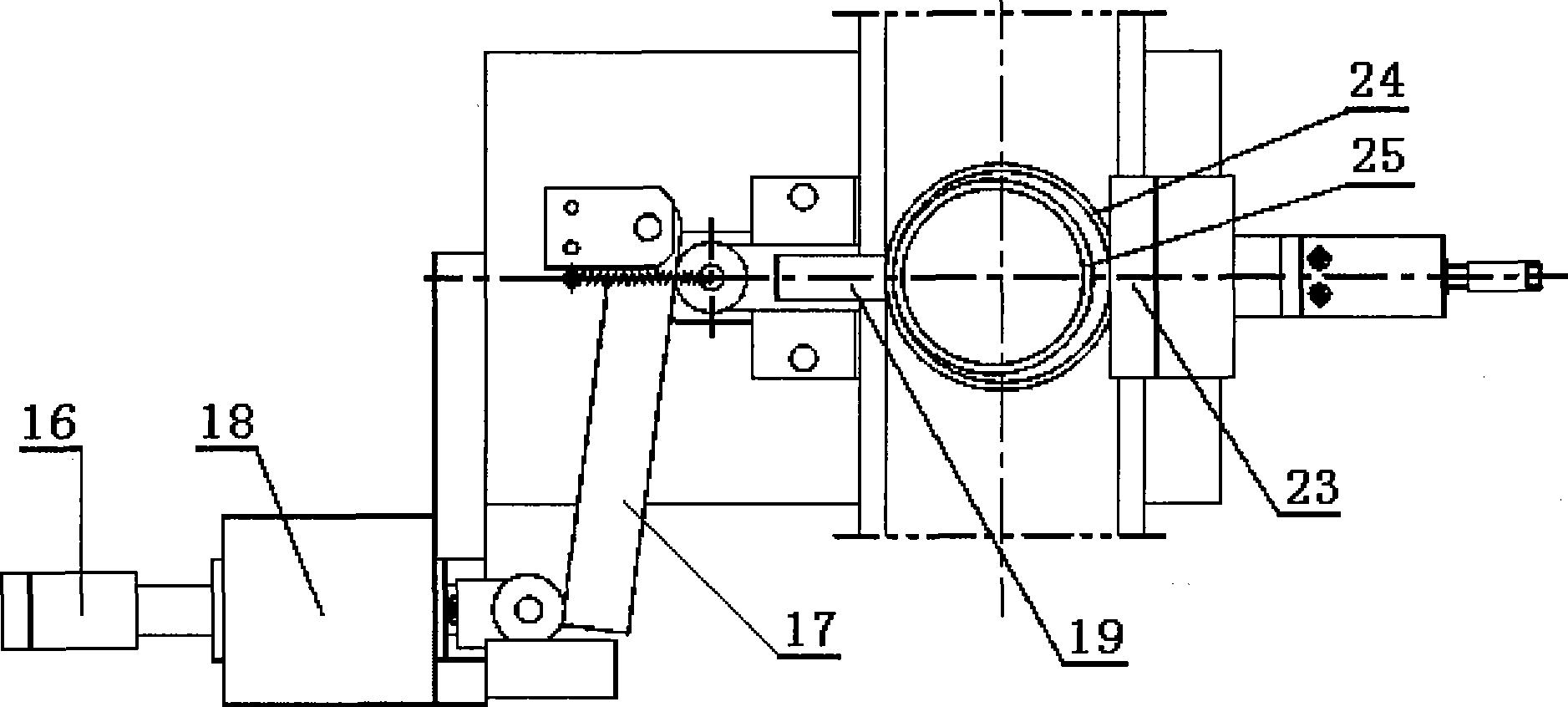

[0019] exist figure 1 and figure 2 Among them, the main body of the bottom-up ball-feeding safety type bearing ball loading system of the present invention includes a ball loading preparation mechanism 1, a ball pushing mechanism 2, an outer ring pressure deformation mechanism 3 and an inner ring centering assembly mechanism 4, and the bearing is composed of Outer ring 24, inner ring 25 and balls, wherein: the ball loading preparation mechanism 1 and the ball pushing mechanism 2 are arranged at the bottom position of the safety bearing ball loading system, and the outer ring deformation mechanism 3 and the inner ring centering mechanism 4 are horizontally arranged above the ball loading preparation mechanism 1 and the pushing ball entry mechanism 2; the ball loading preparation mechanism 1 includes a scoring pipeline 5, The ball receiving mol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com