Non-circular gear transmission and its transmission mechanism

A non-circular gear, transmission mechanism technology, applied in the direction of gear transmission, transmission, belt/chain/gear, etc., can solve the problems of high energy consumption, large negative torque, large peak value, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

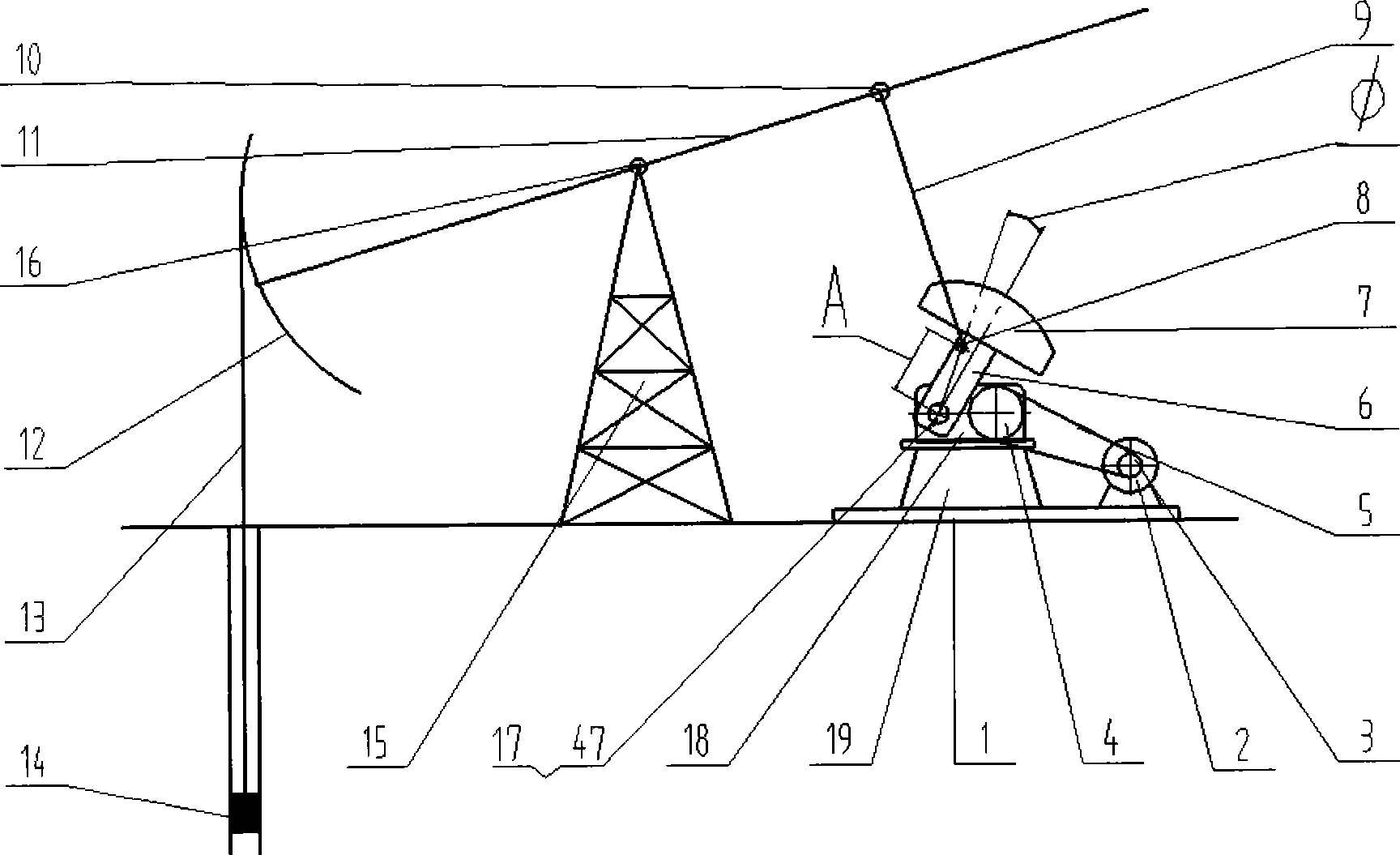

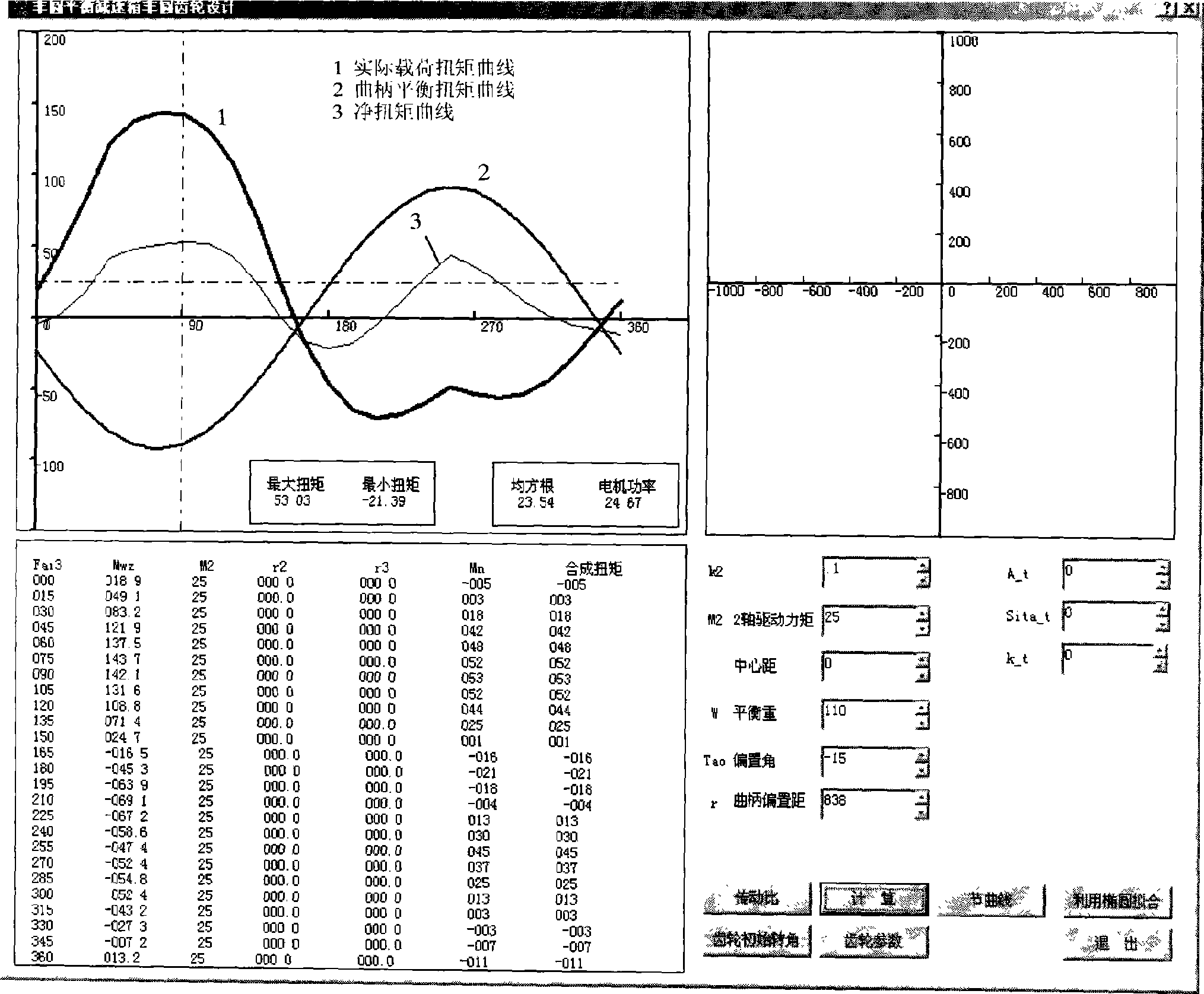

[0070] Non-circular gear gearbox and transmission mechanism thereof described in the present invention ( Figure 4 ), which can provide an output torque that is dynamically adapted and balanced with the host load variation.

[0071] As an example, we installed it on a traditional beam pumping unit, achieving the goals of convenience, stability, and greatly improving the energy-saving effect of the traditional beam pumping unit. Below we describe the embodiment of the present invention respectively.

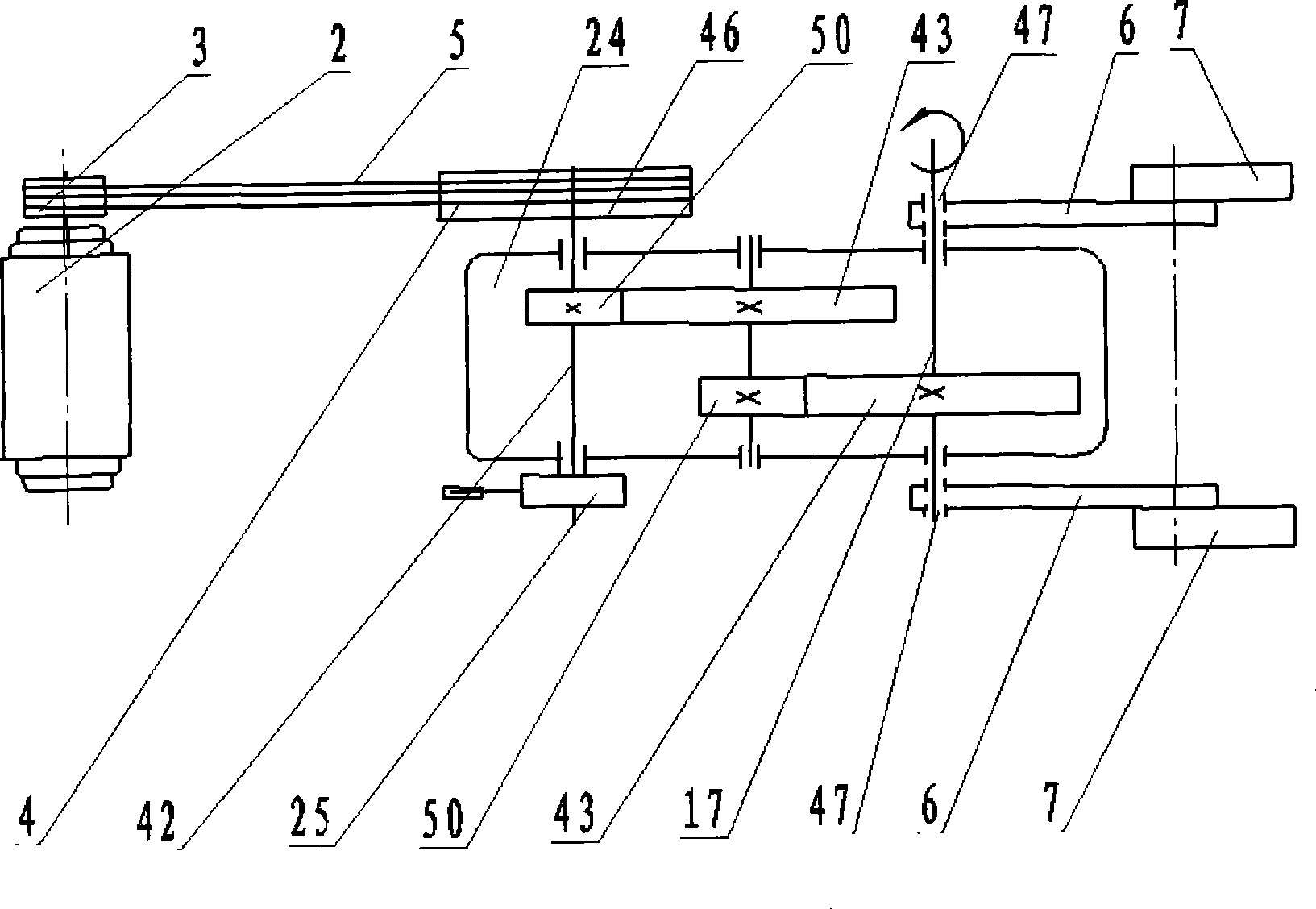

[0072] 1. The specific implementation of the non-circular gear box.

[0073] Figure 5 , Figure 6 , Figure 7 , Figure 8 Shown that the non-circular gear gearbox 24 is composed of a casing 26, a first non-circular gear 27, a second non-circular gear 28, an oil window 29, an output shaft end cover 30, a bolt assembly 31, a ventilation cover 32, an observation window 33, Case cover 34, output shaft bearing 35, large sprocket flat key 36, input shaft bearing 37, non-circular ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com