LCD module and assembling method thereof

A technology for display modules and placement parts, applied in identification devices, nonlinear optics, instruments, etc., can solve the problems of time-consuming and labor-intensive, increased production costs, etc., to avoid displacement or deformation, eliminate noise, and reduce the possibility of damage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

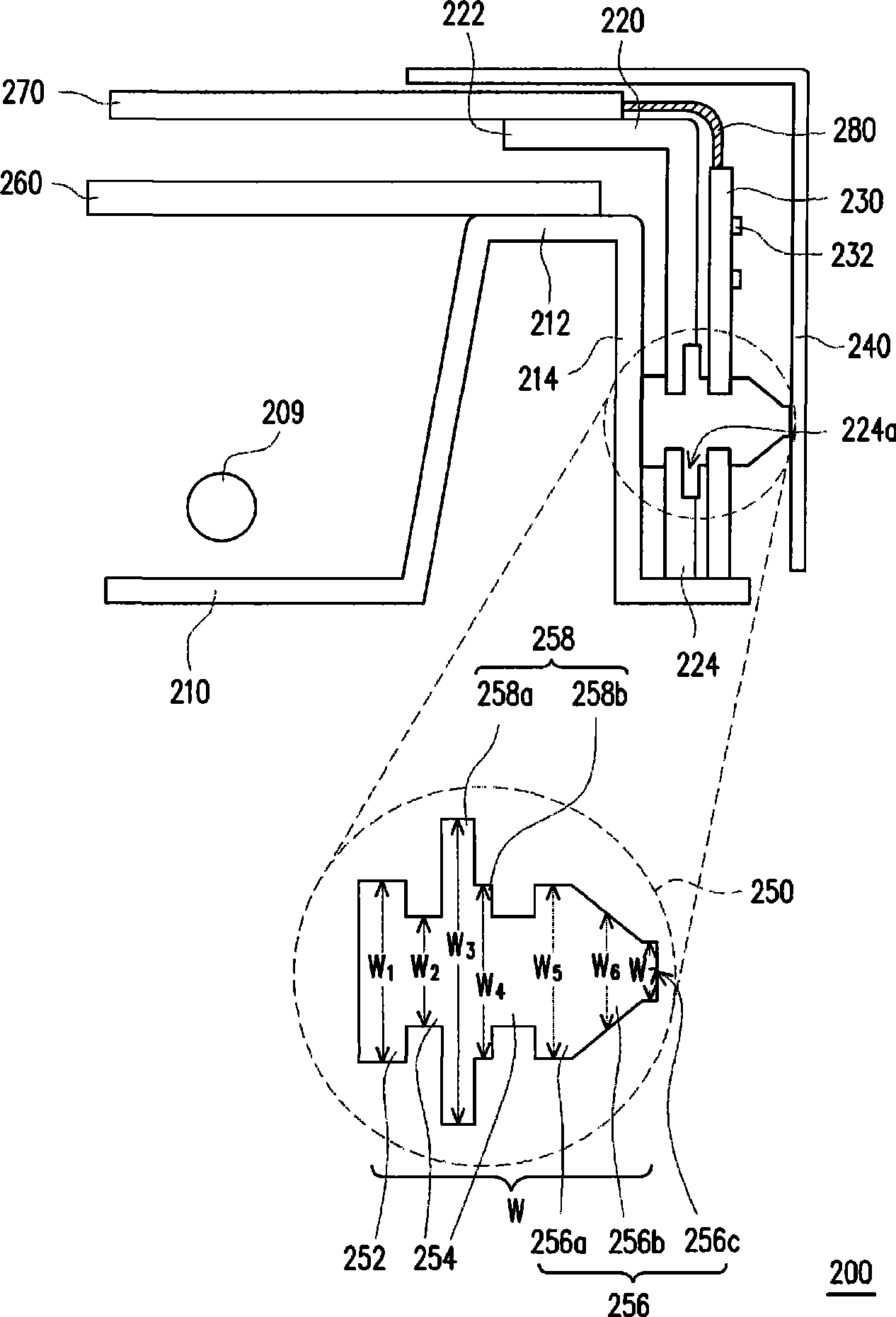

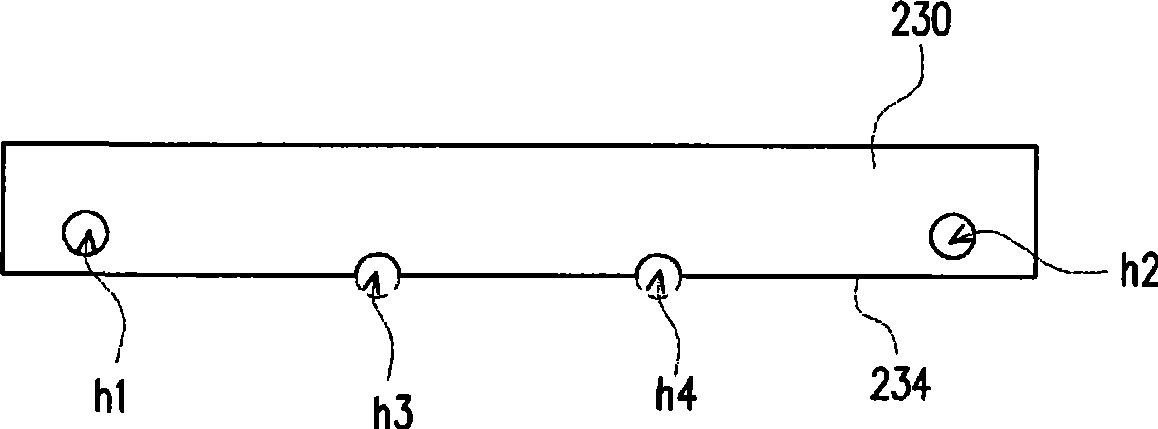

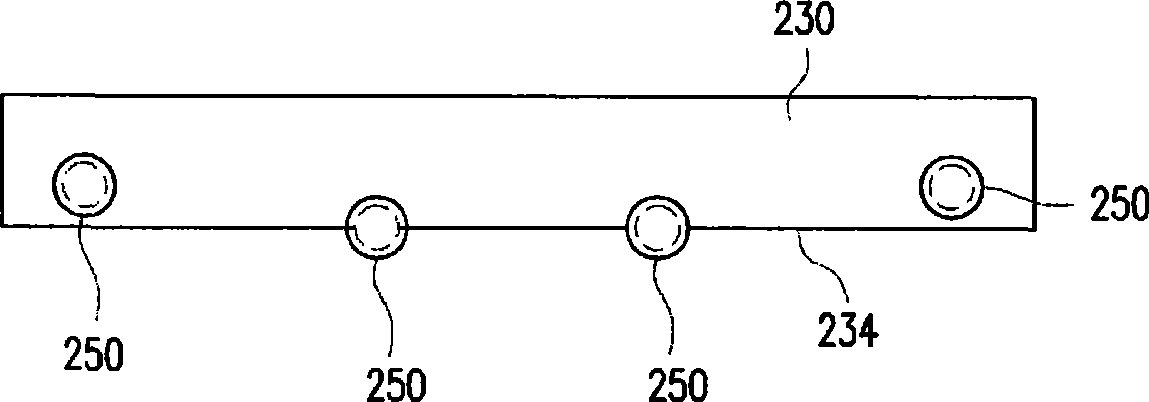

[0075] In order to avoid the above-mentioned problems in the prior art, the present invention designs an elastic tenon between the front frame and the back plate of the display module to provide a good fixing effect for the circuit board of the display module. The good elasticity of the elastic tenon can provide the shock absorbing effect of the display module, so that the flexible circuit board arranged between the circuit board and the display panel will not be pulled and damaged during the process of carrying the display module. In addition, through the configuration of the elastic tenon, the display module can have a slight gap between the front frame and the circuit board, so as to avoid the problem of short circuit caused by the chips on the circuit board contacting the front frame. Furthermore, the elastic tenon can have different types of changes, and the assembler can choose according to the actual design and demand, so as to make the assembly process smoother. A numb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com