Product management display system with trackless pusher mechanism

A display system, thruster technology, applied in the field of shelf components, can solve problems such as backward bending, track obstruction, thruster system fouling or sticky material obstruction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

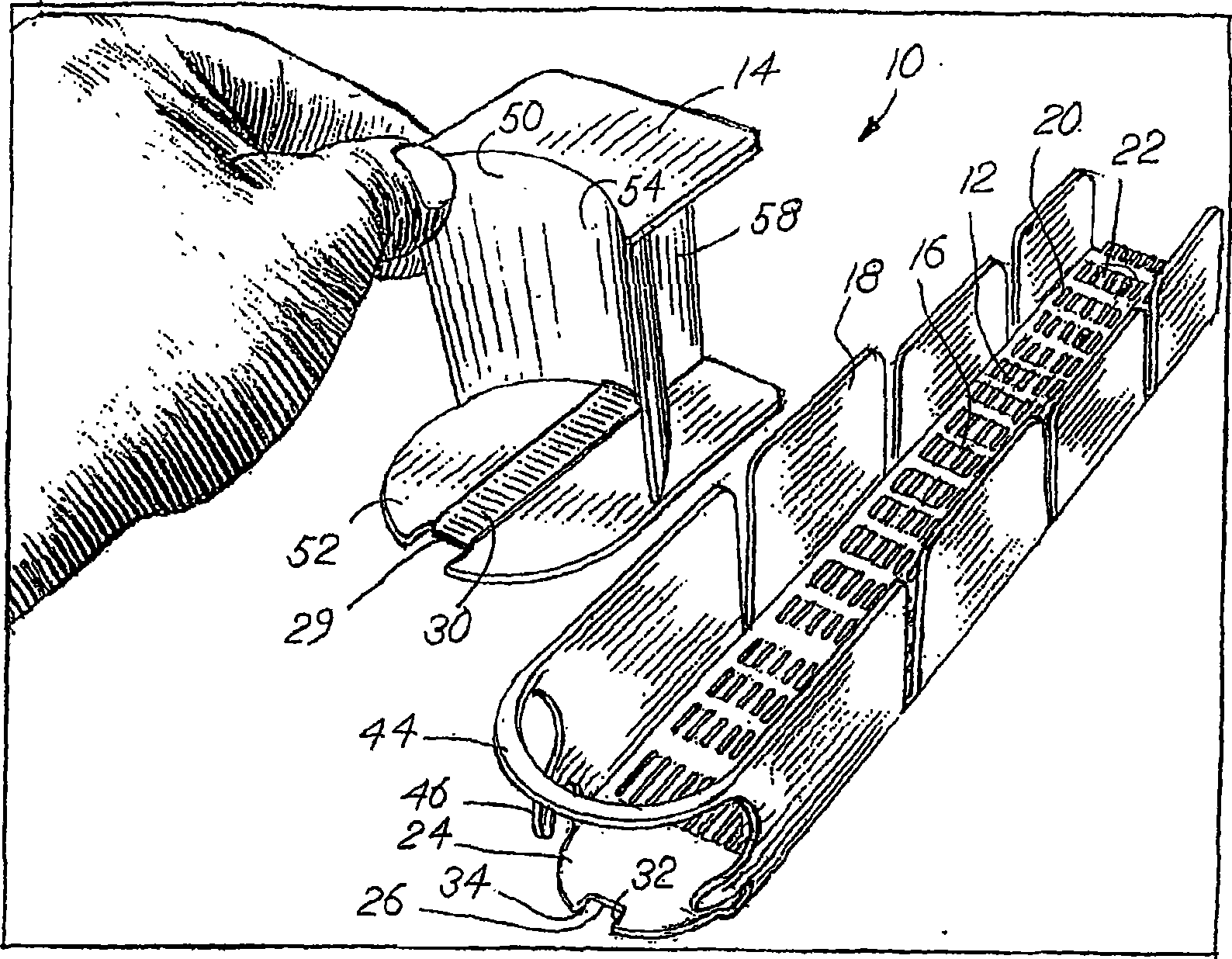

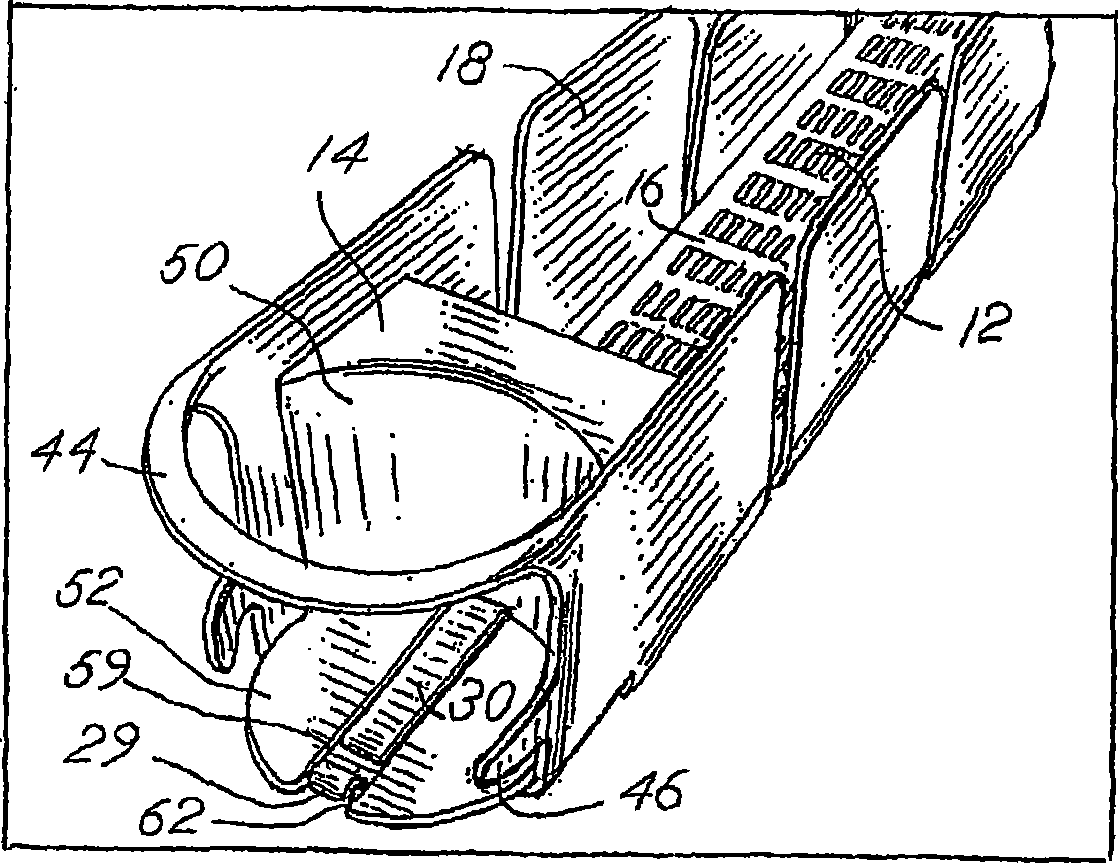

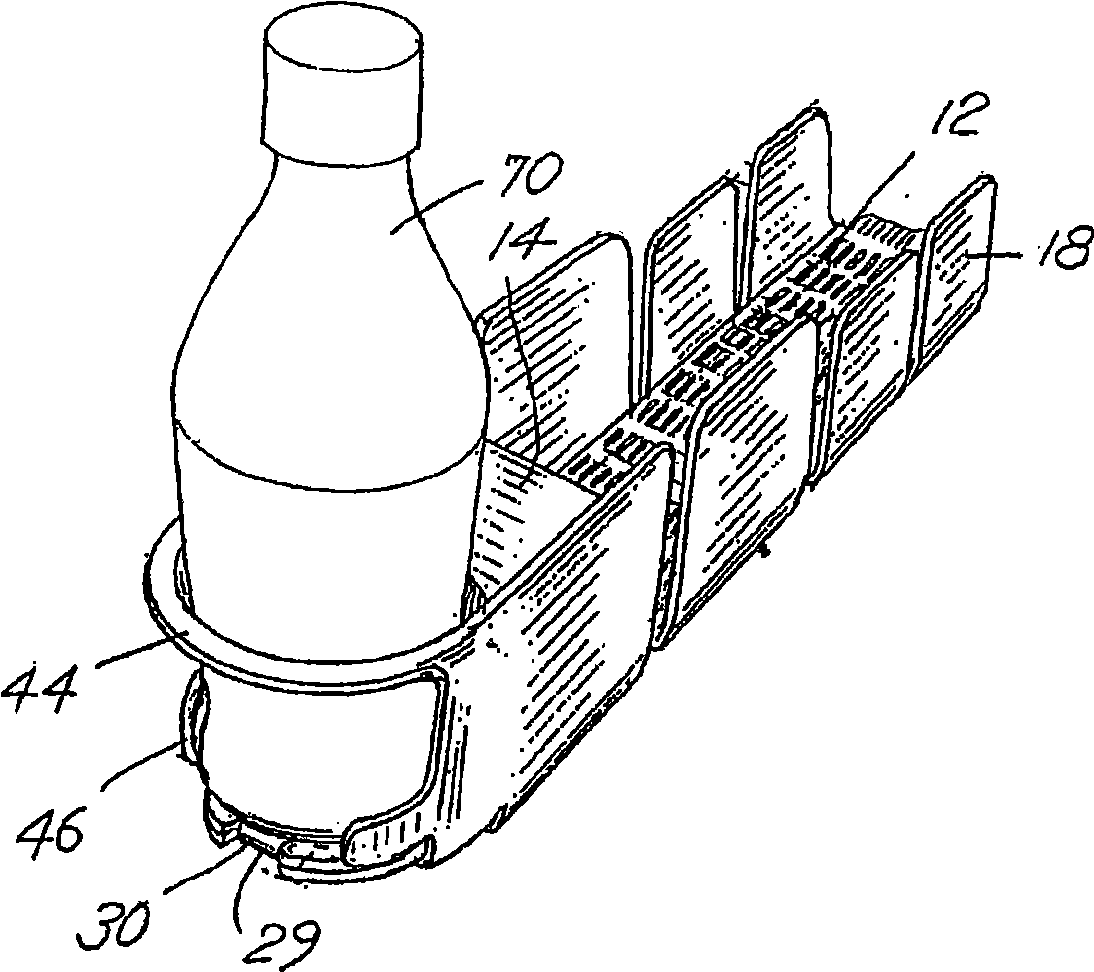

[0034] There may be various embodiments of the present invention. Referring to the drawings in which like reference numerals indicate similar elements, figure 1 It is an exploded perspective view of an exemplary embodiment of the present invention. The exemplary vending system 10 includes a product dispensing tray 12 with an exemplary trackless pusher mechanism 14 disposed therein. As will be described in more detail below, the pusher mechanism 14 is fitted within the tray 12 and can be moved without the use of rails, rails or guides commonly used to hold conventional pusher mechanisms on a tray or tray floor. Slide along the surface of the tray. The propeller mechanism defines a propeller vane and a propeller floor extending forward of the propeller vane. A coil spring is extendable across the pusher floor and is operably connected to the tray in an advanced position on the tray. In one aspect of the invention, the product to be sold may be placed in the tray in front of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com