Dust collector

A technology of dust collection device and dust collection part, which is applied in the direction of external electrostatic separator, solid separation, electrostatic separation, etc., can solve the problems such as difficulty in miniaturization of the device, difficulty in achieving high performance, small dust collection area, etc., and achieve the goal of Miniaturization, high performance, and increased dust collection area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

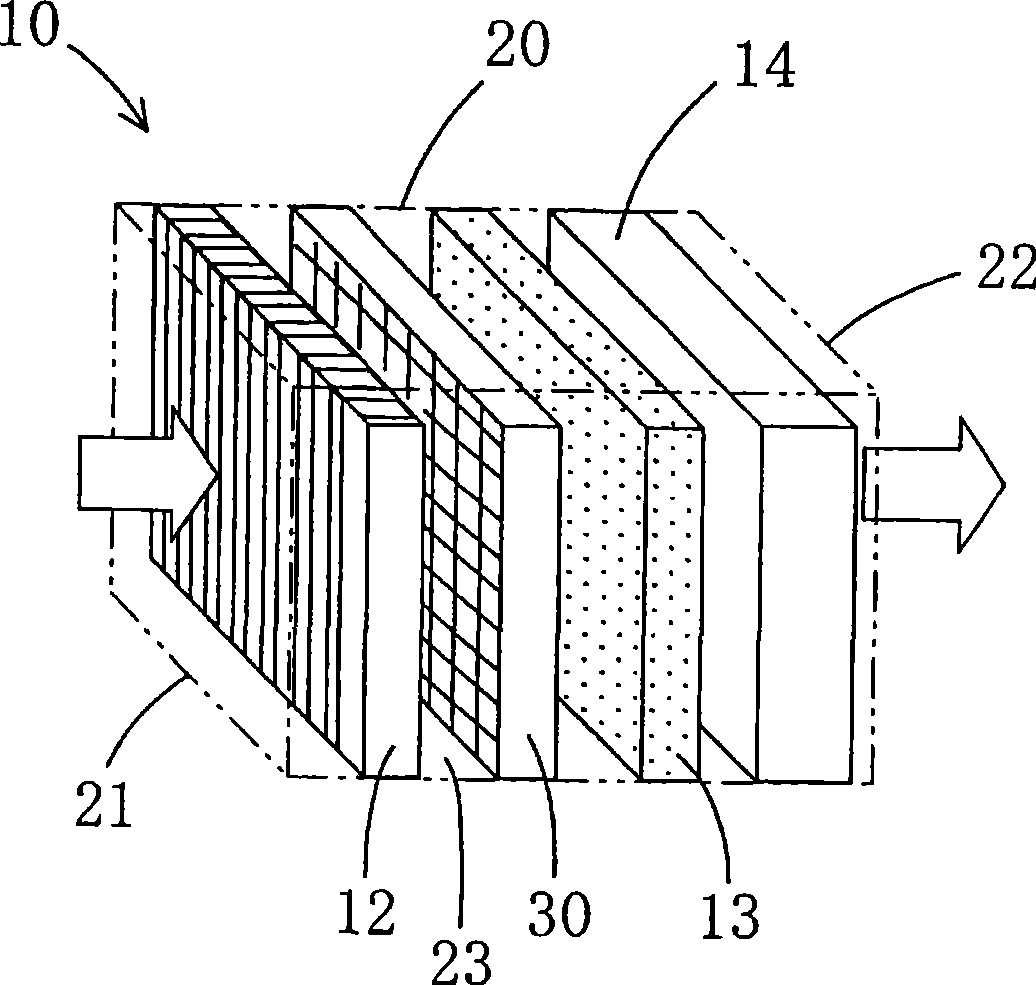

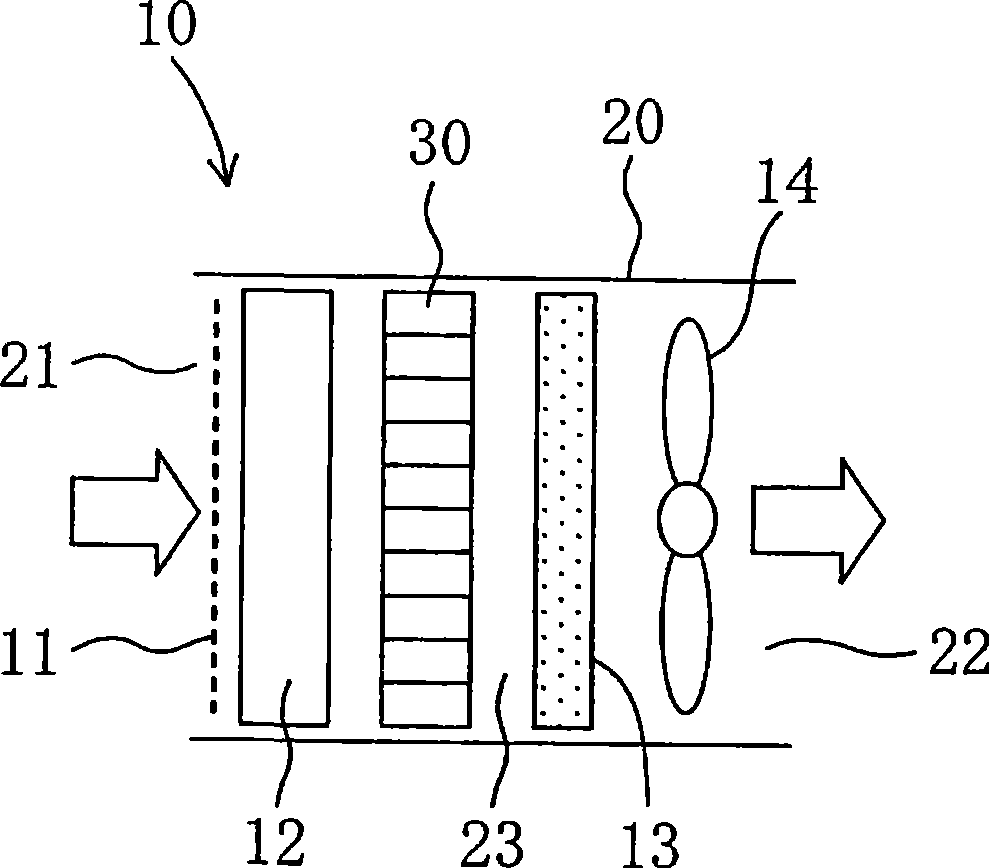

[0079] like figure 1 and figure 2 As shown, the air cleaner 10 in this embodiment constitutes the dust collecting device of the present invention, and is, for example, a domestic air cleaning device used in general households, small-scale stores, and the like.

[0080] The above-mentioned air cleaner 10 includes a housing 20 , and includes a preliminary filter 11 installed inside the housing 20 , a charging unit 12 , a dust collecting unit 30 , a catalyst filter 13 and a fan 14 .

[0081] The casing 20 is formed, for example, as a rectangular parallelepiped long container with an air inlet 21 on the front, an air outlet 22 on the back, and an air passage 23 inside. The preliminary filter 11 , charging unit 12 , dust collecting unit 30 , catalyst filter 13 , and fan 14 are arranged in order from the suction port 21 to the blowing port 22 .

[0082] The preliminary filter 11 constitutes a filter for trapping relatively large dust contained in the air sucked into the casing 20...

no. 2 approach

[0117] Next, a second embodiment of the present invention will be described in detail with reference to the drawings.

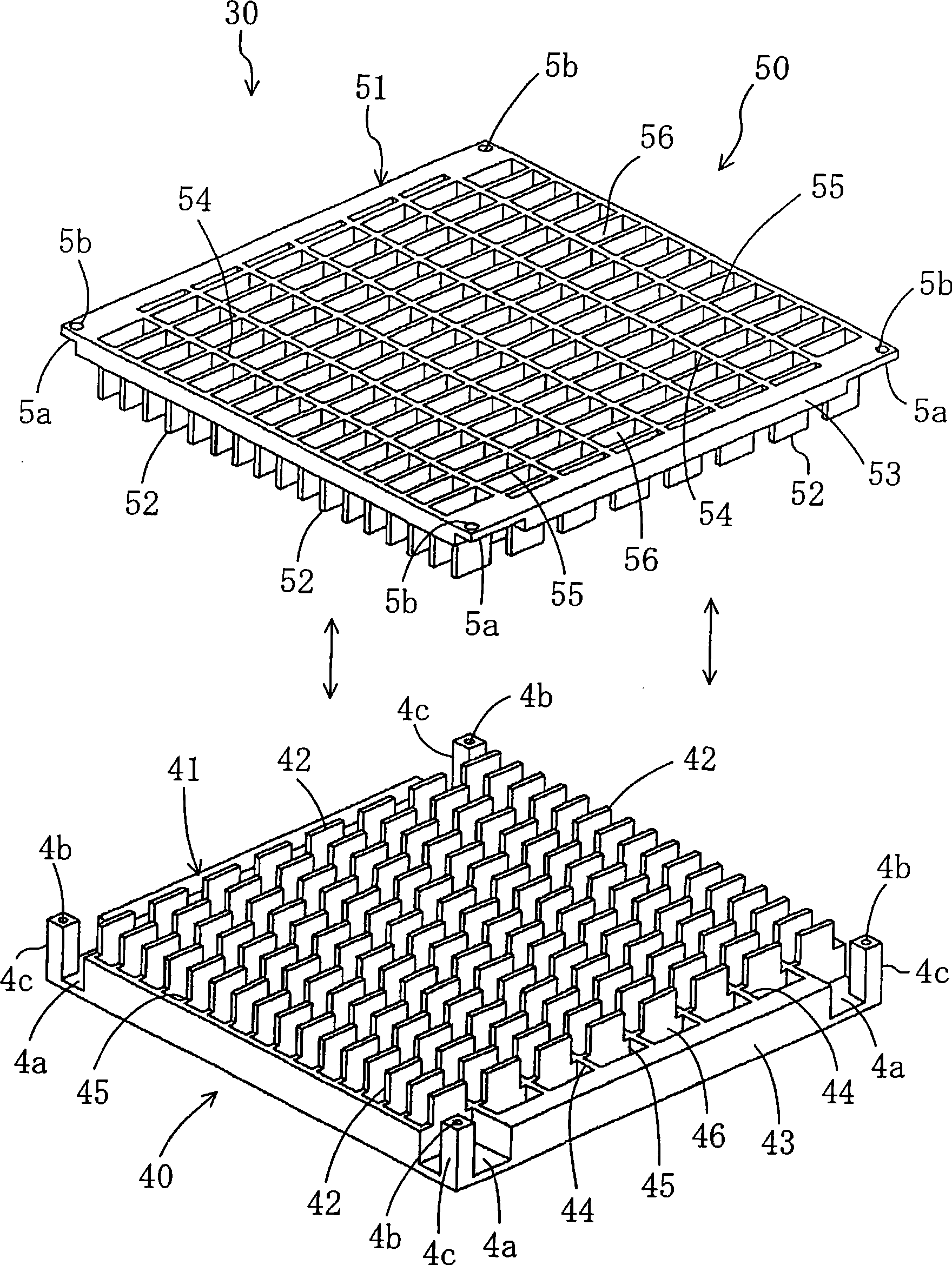

[0118] like Image 6 As shown, in this embodiment, the dust collecting electrode 40 is made of conductive metal instead of both the dust collecting electrode 40 and the high voltage electrode 50 being made of conductive resin in the first embodiment.

[0119] That is, the dust collecting electrode 40 is formed of a thin metal plate such as stainless steel, and the high voltage electrode 50 is formed of a conductive resin as in the first embodiment.

[0120] Like the first embodiment, the dust collecting electrode 40 is formed in a rectangular shape and includes a base part 41 and many protruding parts 42. Isolation part 45. Furthermore, the protruding member 42, the frame body 43, the vertical spacer 44, and the horizontal spacer 45 are each formed of a thin conductive metal plate.

[0121] As in the first embodiment, the protruding part 42 of the dust col...

no. 3 approach

[0125] Next, a third embodiment of the present invention will be described in detail with reference to the drawings.

[0126] like Figure 7 and Figure 8 As shown, this embodiment is a structure in which only the high-voltage electrode 50 is embedded in the dust-collecting electrode 40 , replacing the structure in which the dust-collecting electrode 40 and the high-voltage electrode 50 are embedded in each other in the first embodiment.

[0127] That is, the dust collecting electrode 40 is formed in a rectangular shape and includes one base member 41 . The base member 41 includes a frame body 43 , a plurality of vertical partition members 44 , and a plurality of horizontal partition members 45 . Therefore, the dust collecting electrode 40 in this embodiment does not include many protruding parts 42 in the first embodiment, and the dust collecting electrode 40 is formed in a simple lattice structure.

[0128] On the other hand, like the first embodiment, the high-voltage el...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com