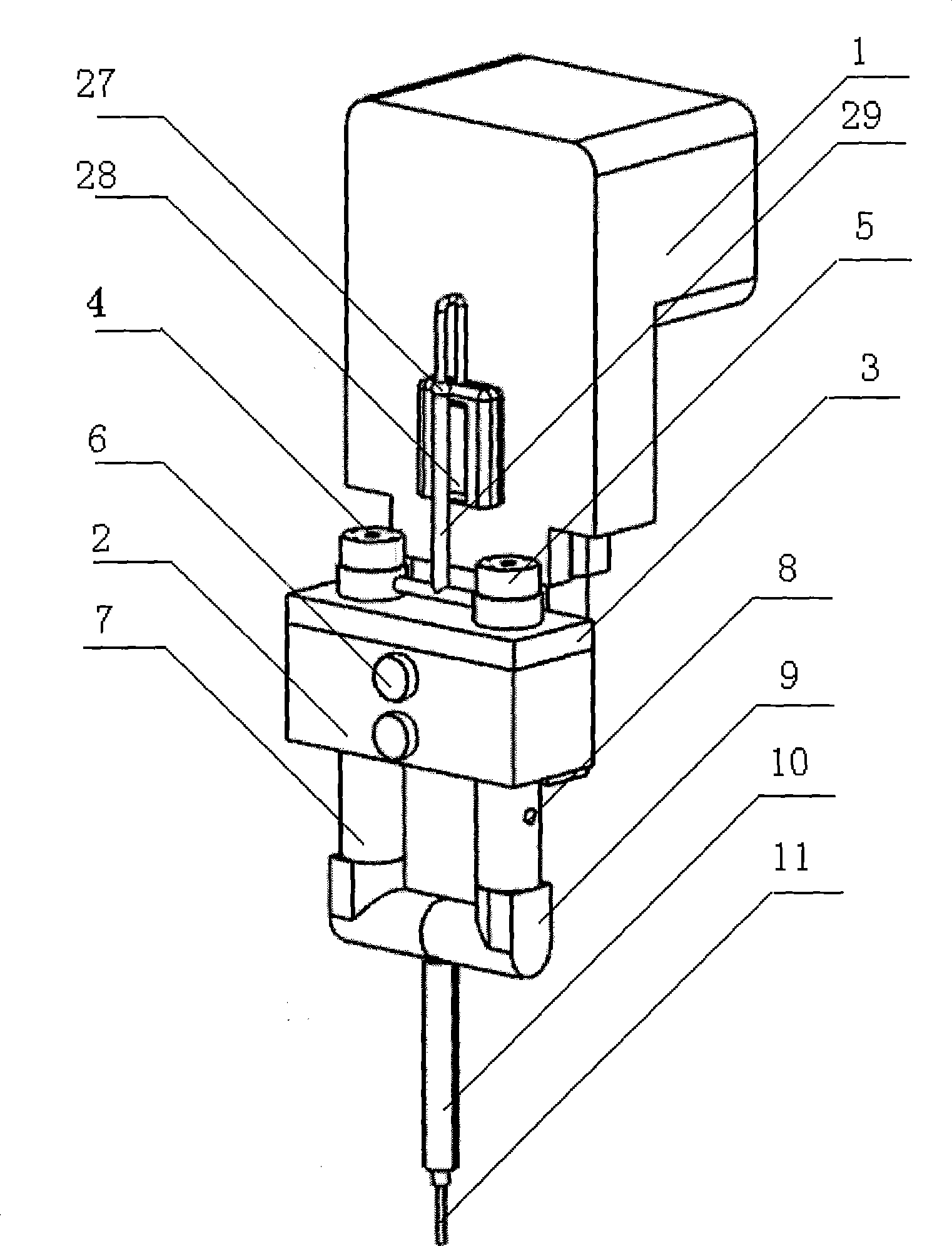

Accurate double-liquid glue dropping device

A glue dispensing device, precise technology, applied to the surface coating liquid device, coating, etc., can solve the problem that the mixing ratio of the two glues cannot be achieved, the gel and dripping cannot be well solved, and the production efficiency is not ideal and other problems to achieve the effect of avoiding gel phenomenon, simple structure and avoiding dripping phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

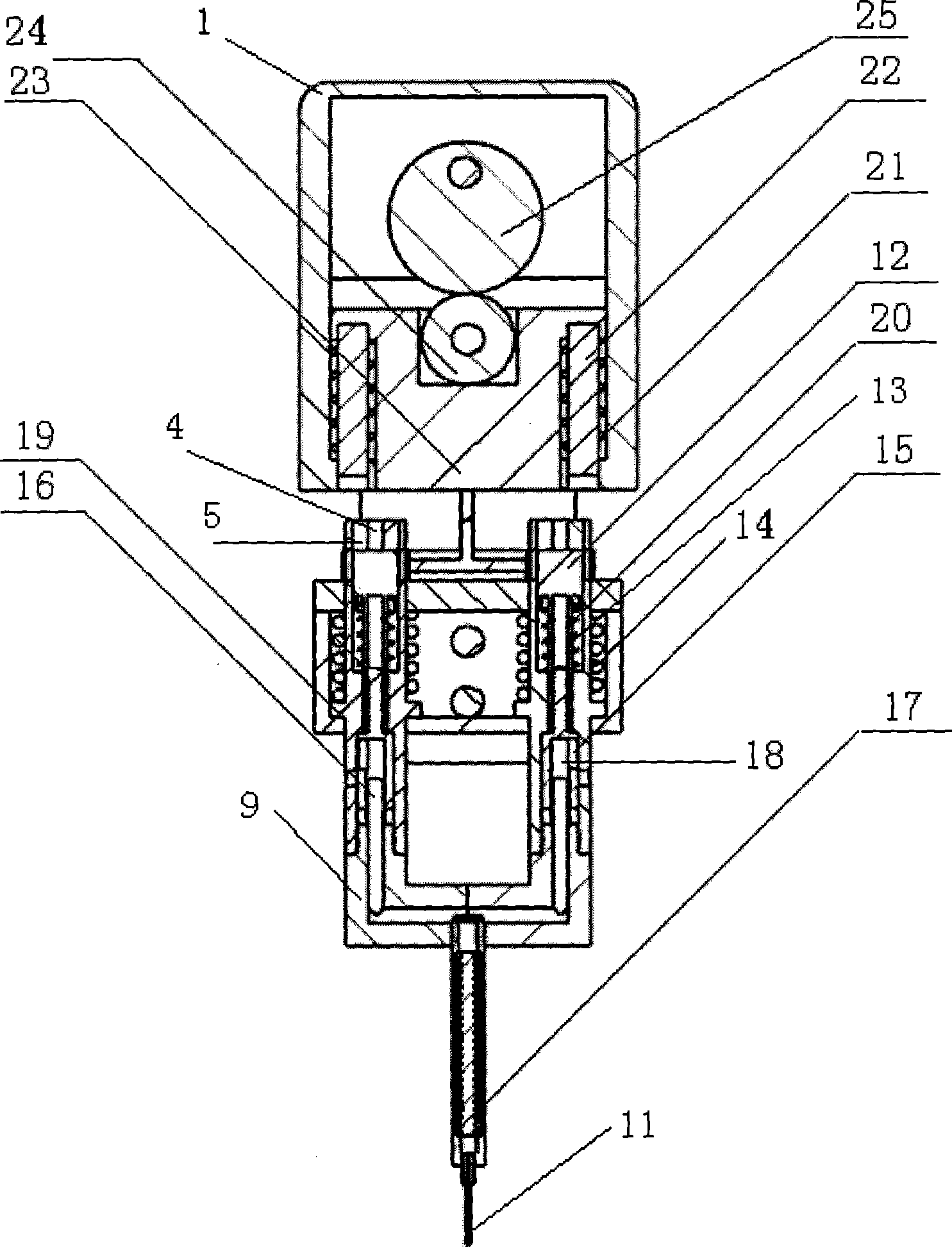

[0014] Referring to the accompanying drawings, the precision double-liquid dispensing device includes a frame 1, a container 2, and a needle nozzle 11 that are sequentially installed from top to bottom. The frame 1 has a cavity, and a lifting rod 23 and a cam 25 are installed in the cavity. , both sides of lifting rod 23 are fixed with guide rod 22 respectively, and guide rod 22 is covered with supporting spring 21, and the upper end of supporting spring 21 props against lifting rod 23 top walls, and the lower end props against the bottom wall of frame 1 cavity. The top of lifting rod 23 is equipped with rotating shaft, and roller 24 is arranged on the rotating shaft, and roller 24 is in close contact with cam 25, and roller 24 can rotate around the rotating shaft under the drive of cam 25. The elevating rod 23 protrudes from the frame 1 and is connected to the container 2 with screws 6. There are two hollow rods 7 with convex circles 19 in the container 2, and the two hollow r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com