Shipborne stirring station

A mixing station and ship-mounted technology, which is applied in the field of concrete production equipment, can solve the problems that concrete mixing equipment is not suitable for mobile feeding, the degree of automation of ship-borne mixing stations is low, and the safety and reliability cannot be guaranteed. The effect of high practicability, high degree of automation and fast speed

Inactive Publication Date: 2010-11-10

CHINA CONSTR SECOND ENG BUREAU LTD +2

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

In order to overcome the deficiencies of the existing technology and complete the construction of water facilities with quality and quantity, the present invention provides a ship-mounted mixing plant to solve the problem that the existing concrete mixing equipment is not suitable for ship-borne water surface mobile feeding, unreasonable layout, Technical problems that cannot be continuously produced; and solve the problems of low automation, slow concrete production speed, poor measurement accuracy, and unguaranteed safety and reliability of existing ship-mounted mixing plants

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

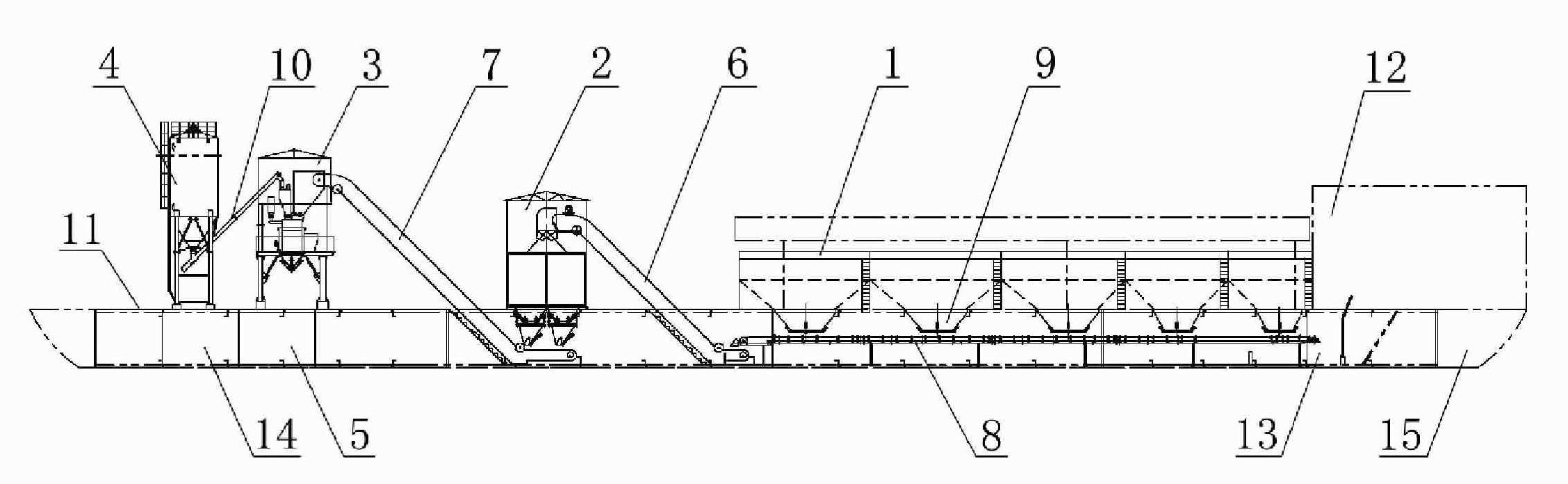

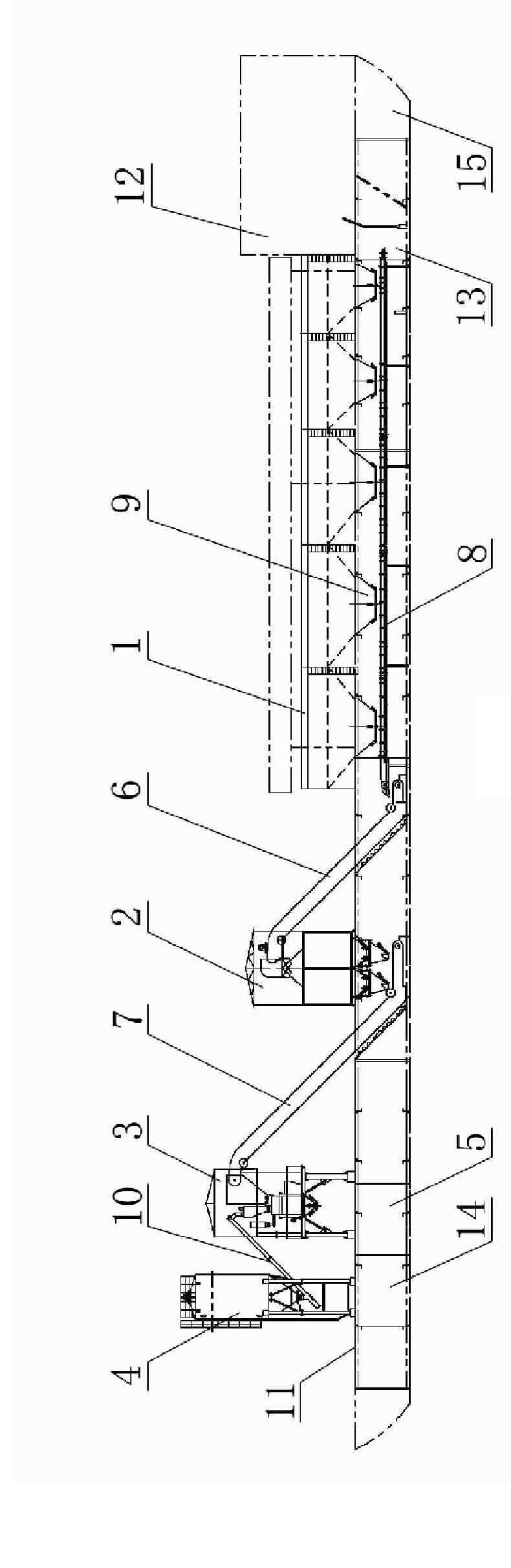

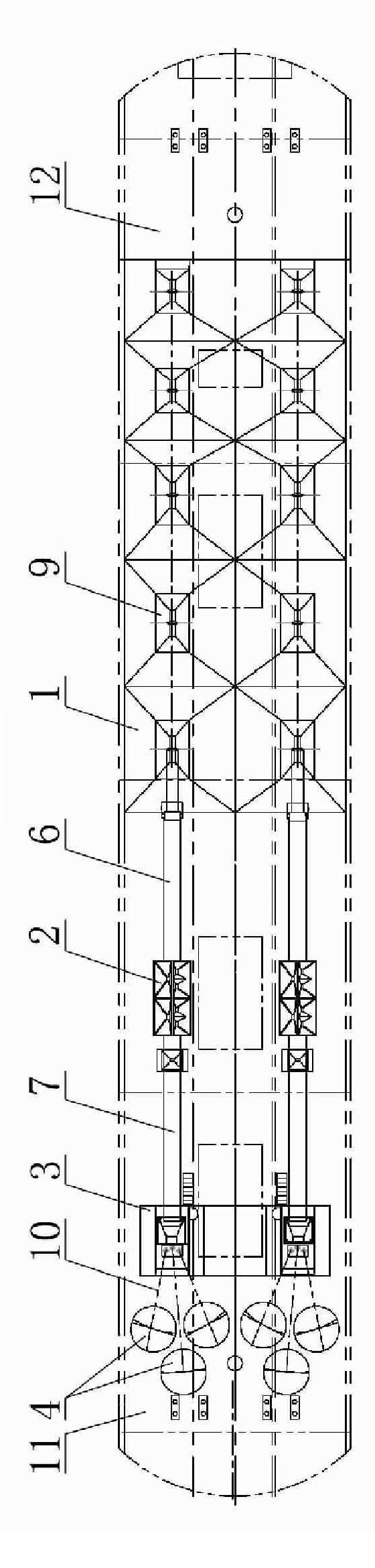

A shipborne type mixing station comprises the following components: a ship body which comprises a synthetic chamber, and mixing stations positioned on the ship body. Two sets of mixing stations are totally installed on the ship body and are installed symmetrically along a longitudinal axis of ship body. Each set of mixing station comprises a sandstone aggregate storage bin, a material preparing building and a powder material bin which are distributed in order along the longitudinal direction of ship body. The ship bin of ship body which is at the side of power material bin is internally installed with water, an adjunct bin and a sedimentation tank. The ship bin of ship body which is at the side of sandstone aggregate storage bin is internally installed with a water discharge bin that is positioned at the ship body end position at the side of sandstone aggregate storage bin. The mixing station of the invention has the advantages of high reliability, high practicability, excellent use effect, and realization of mobile batch production on water surface. The mixing station can be stopped adjacently to the bridge piper in construction. The concrete is manufactured after mixing sand, stone and cement on the conveying lighter. Then the concrete is poured in the bridge pier continuously.

Description

Ship-mounted mixing plant technical field The invention relates to equipment for producing concrete, in particular to a ship-mounted concrete mixing station used in working conditions such as rivers and lakes. Background technique my country's inland waters are vast, and with the development of the construction of the motherland, it is necessary to build many transportation and water conservancy facilities in the waters. A large amount of concrete is required for the construction of these facilities, and usually these mixing equipment for producing concrete are erected on land around water bodies, and the concrete is delivered by methods such as delivery pumps or ships. But the reliability of these methods is relatively poor, will force the ship to suspend sailing when running into the bad weather of thick fog when transporting by ship, and be difficult to get rid of in case pipe is stuck on the water surface when adopting delivery pump to transport. This will inevitably ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): B28C9/04B28C5/08B28C7/14B28C7/16

Inventor 白文山申明远董素贞牛灿伟高博罗琼英钟燕

Owner CHINA CONSTR SECOND ENG BUREAU LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com