Independent special-shaped tube negative pressure type compact spinning apparatus

A special-shaped tube and compact spinning technology, applied in spinning machines, textiles, papermaking, drafting equipment, etc., can solve the problems of long-term string movement and radial change, and easy flower collection of rollers and negative pressure suction pipes. Achieve the effect of not easy to gather flowers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

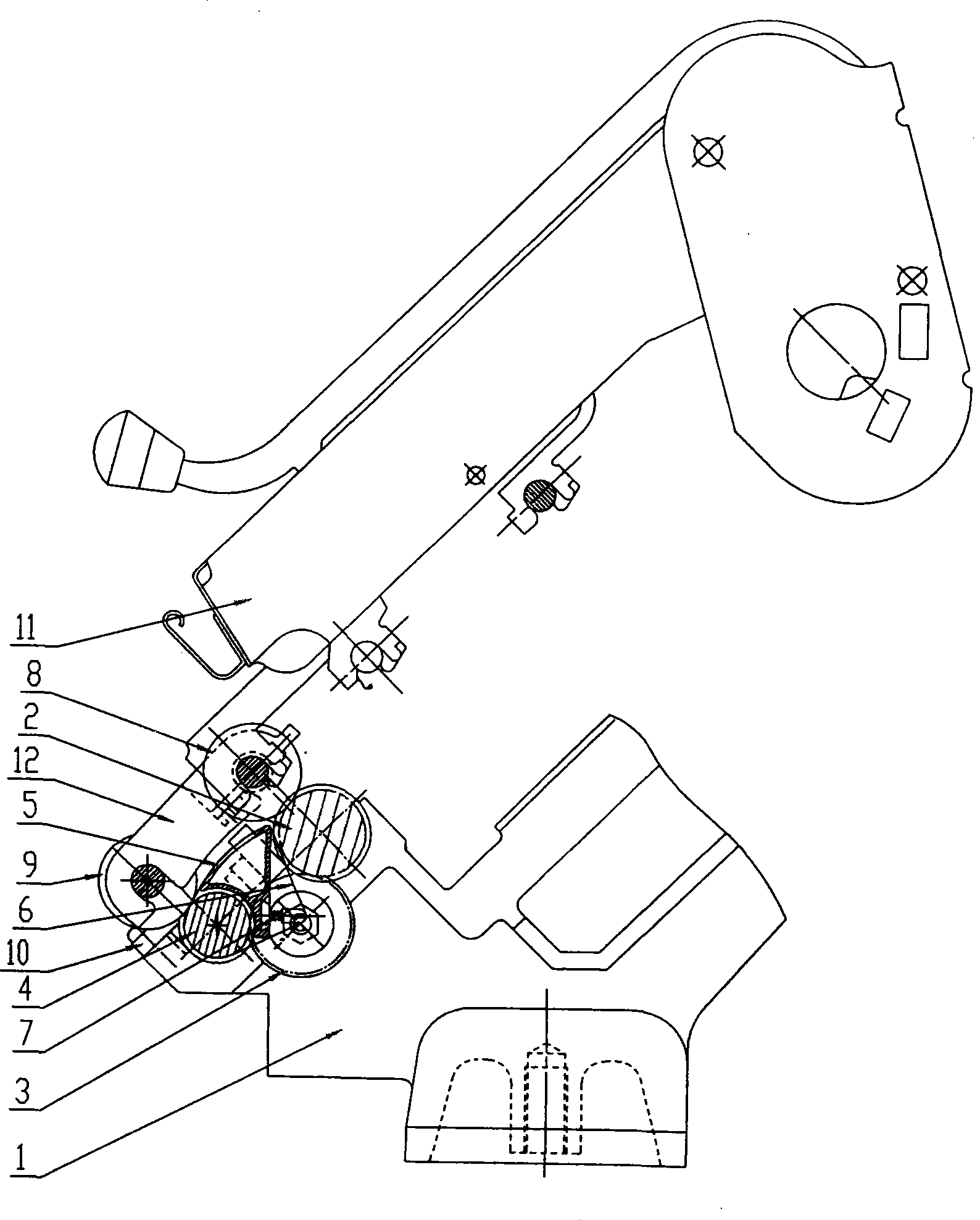

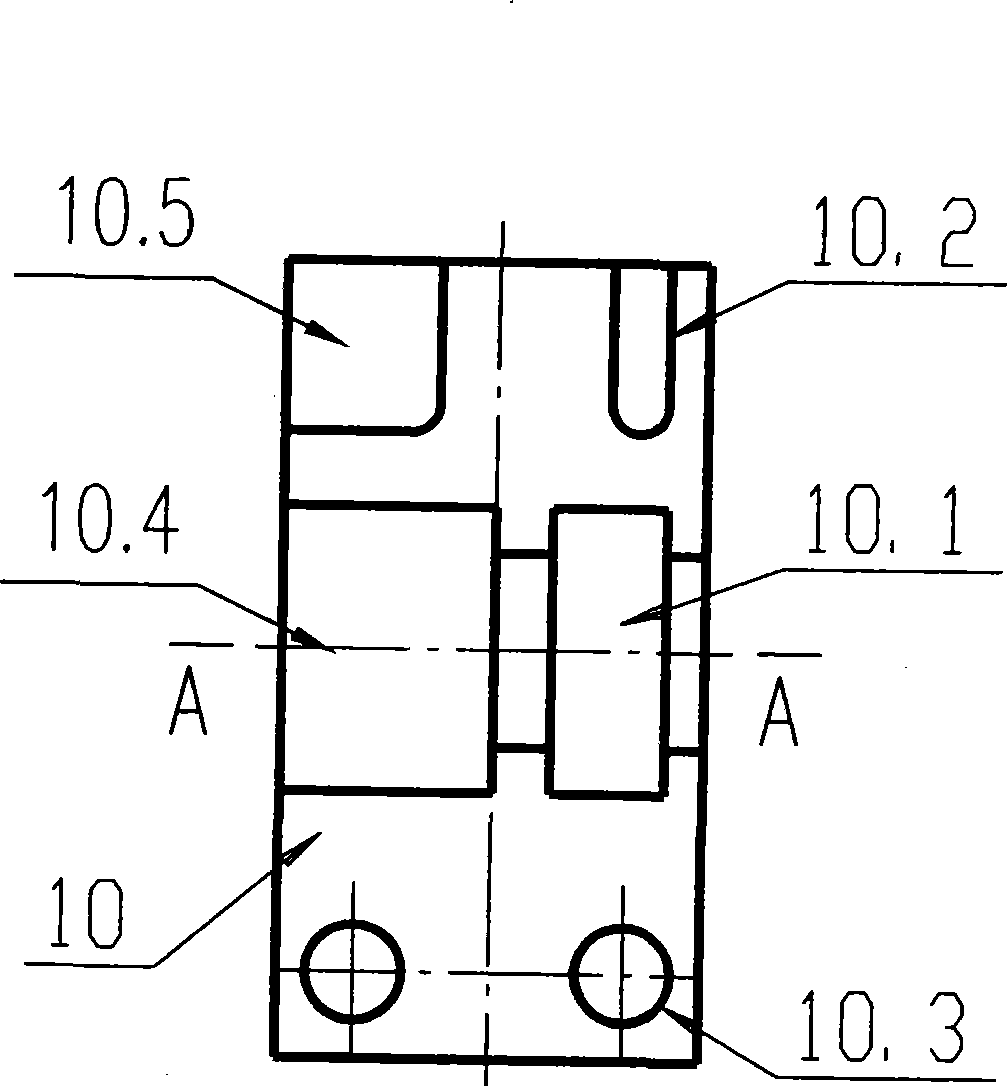

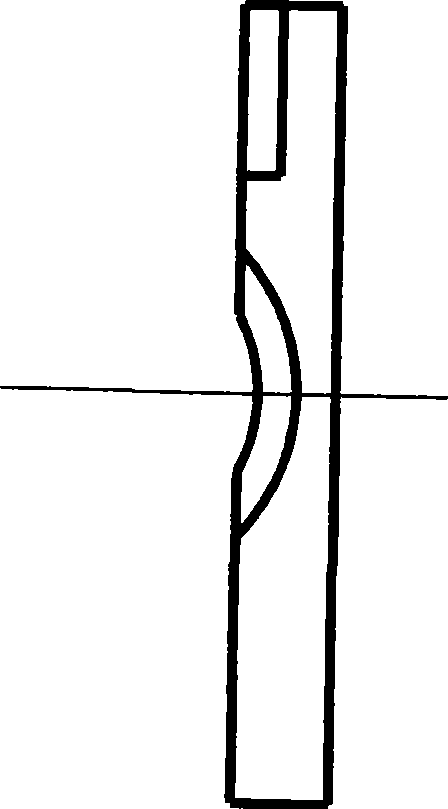

[0031] The present invention includes a roller seat 1, a front roller 2 with a gear, a bridge gear 3, an output roller 4 with a gear, a special-shaped pipe 5 with a negative pressure suction system, a grid set on the special-shaped pipe 5.1 and the output roller 4.1 Ring 6, tensioning device 7 for tensioning grid ring 6, positioning block 10 for output roller and special-shaped pipe positioning, and cradle 11, top roller box 12, front top roller 8 and output top roller 9, Front top roller 8 and output top roller 9 are pressed by top roller box 12 by cradle 11.

[0032] The front roller, the output roller, and the special-shaped pipe are a section between every two roller seats, and each section of the front roller has a gear, which is connected end to end and driven by the front of the car, and the output roller is also a section between every two roller seats. Each section also has a gear, each section is independently installed on the roller seat, and is driven by the bridge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com