Hydraulically actuated electronic limited slip differential for front wheel drive vehicles

A technology of differentials and actuators, used in vehicle components, differential transmissions, transmissions, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

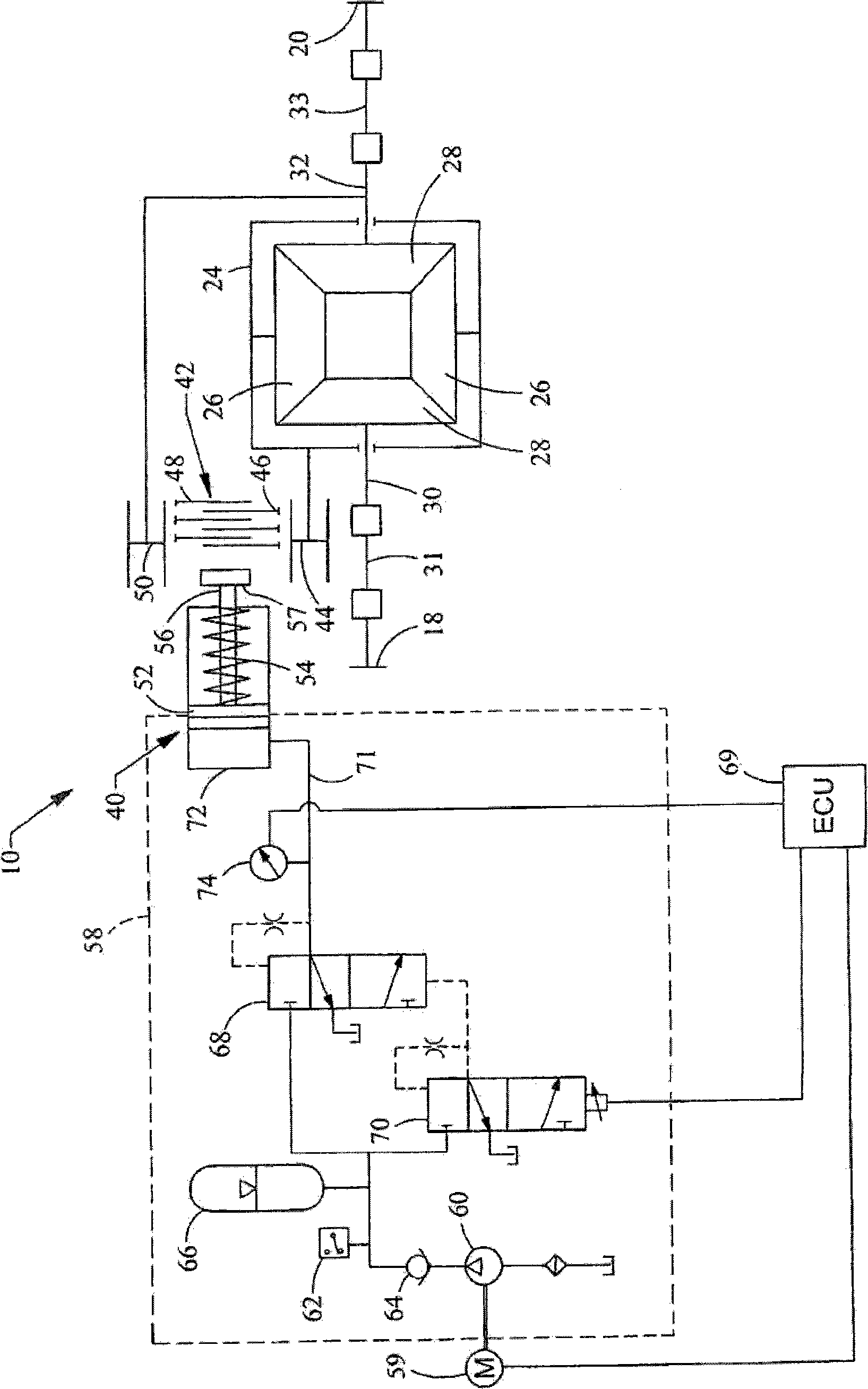

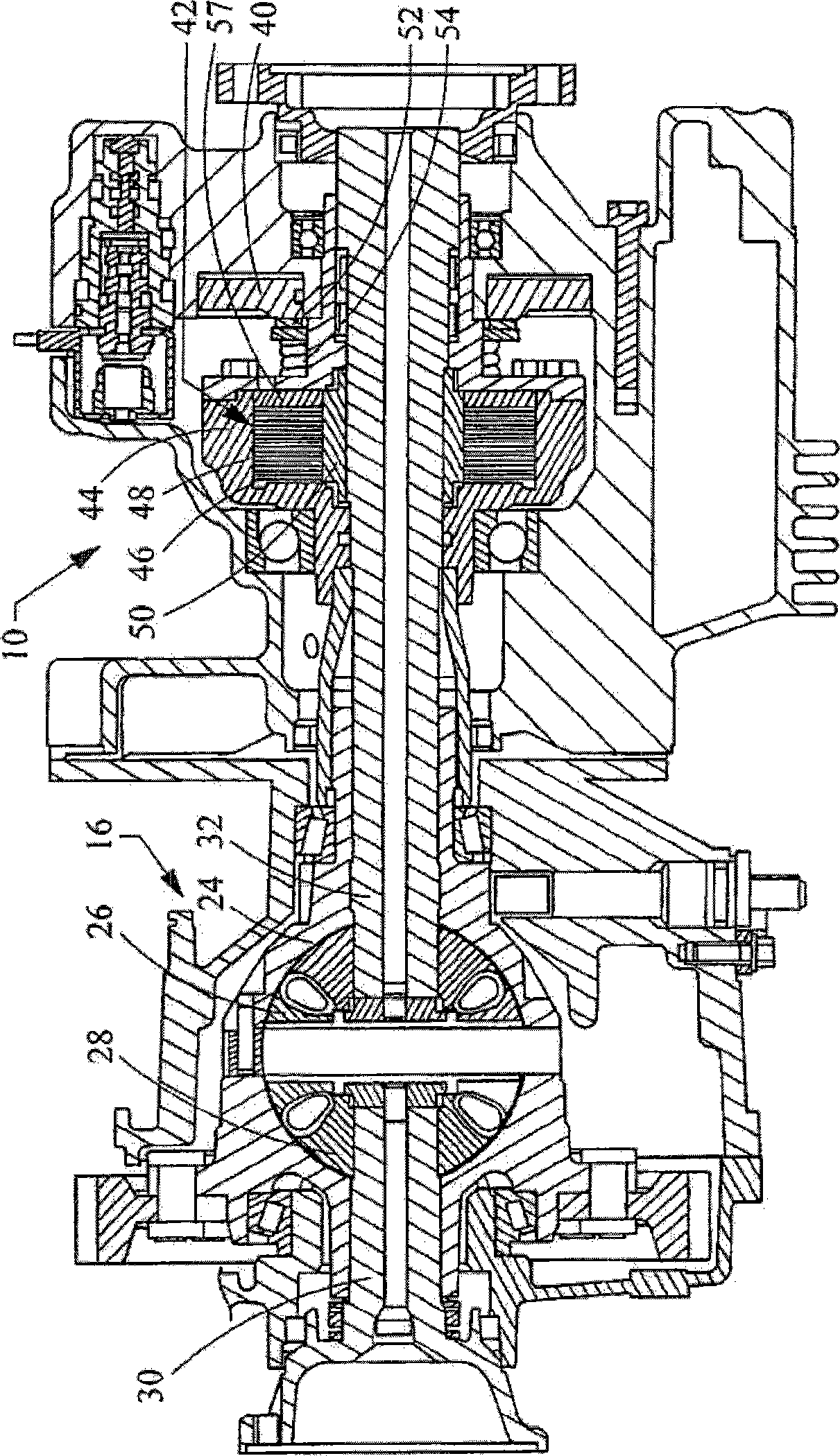

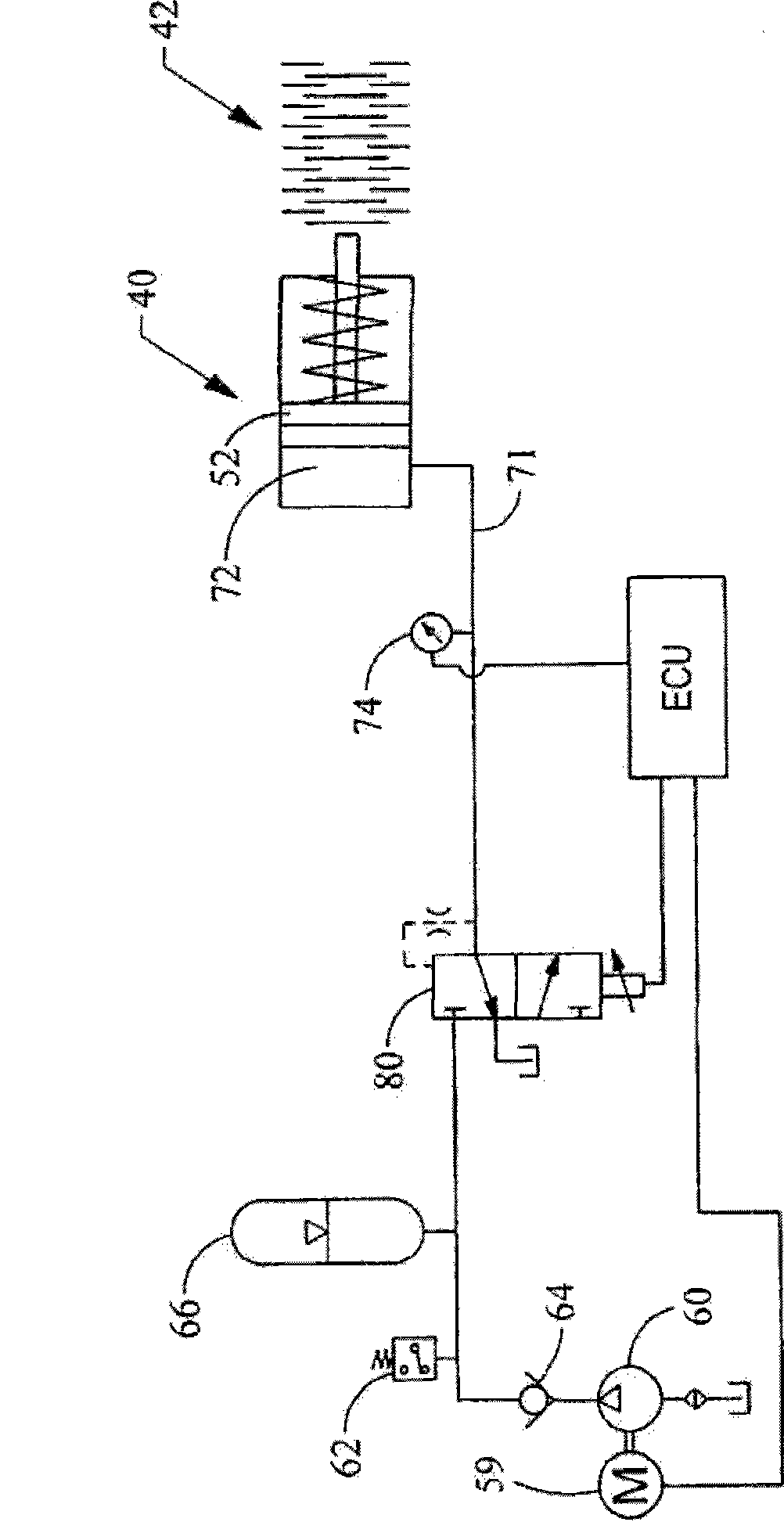

[0010] figure 1 and figure 2 An actuation system for a limited slip differential assembly is provided. The actuation system is indicated generally by reference numeral 10 .

[0011] The differential assembly 16 includes the basic elements of typical differential assemblies including a differential case 24 driven by the driveline output of the vehicle via a gear or chain drive (not shown). out) to drive. A pair of planet gears 26 are rotatable about a common differential shaft mounted to the differential case. These planetary gears 26 mesh with a pair of side gears 28 which in turn are splined or otherwise connected to a pair of Half shafts 31,33. The aforementioned components of the differential assembly 16 are common elements of so-called open differentials. Front-wheel drive vehicles can also use a differential, which is a planetary gearset.

[0012] Under certain low traction conditions it may be desirable to lock or modulate the differential assembly 16 to provide ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com