Gear assembly for driving an electrical switching contact

A transmission device and electric switch technology, applied in electric switches, contact drive mechanisms, contact operation mechanisms, etc., can solve the problems of variation in contact timing, inaccurate transmission characteristics, and troublesome trimming of chute devices. achieve the effect of fast conversion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

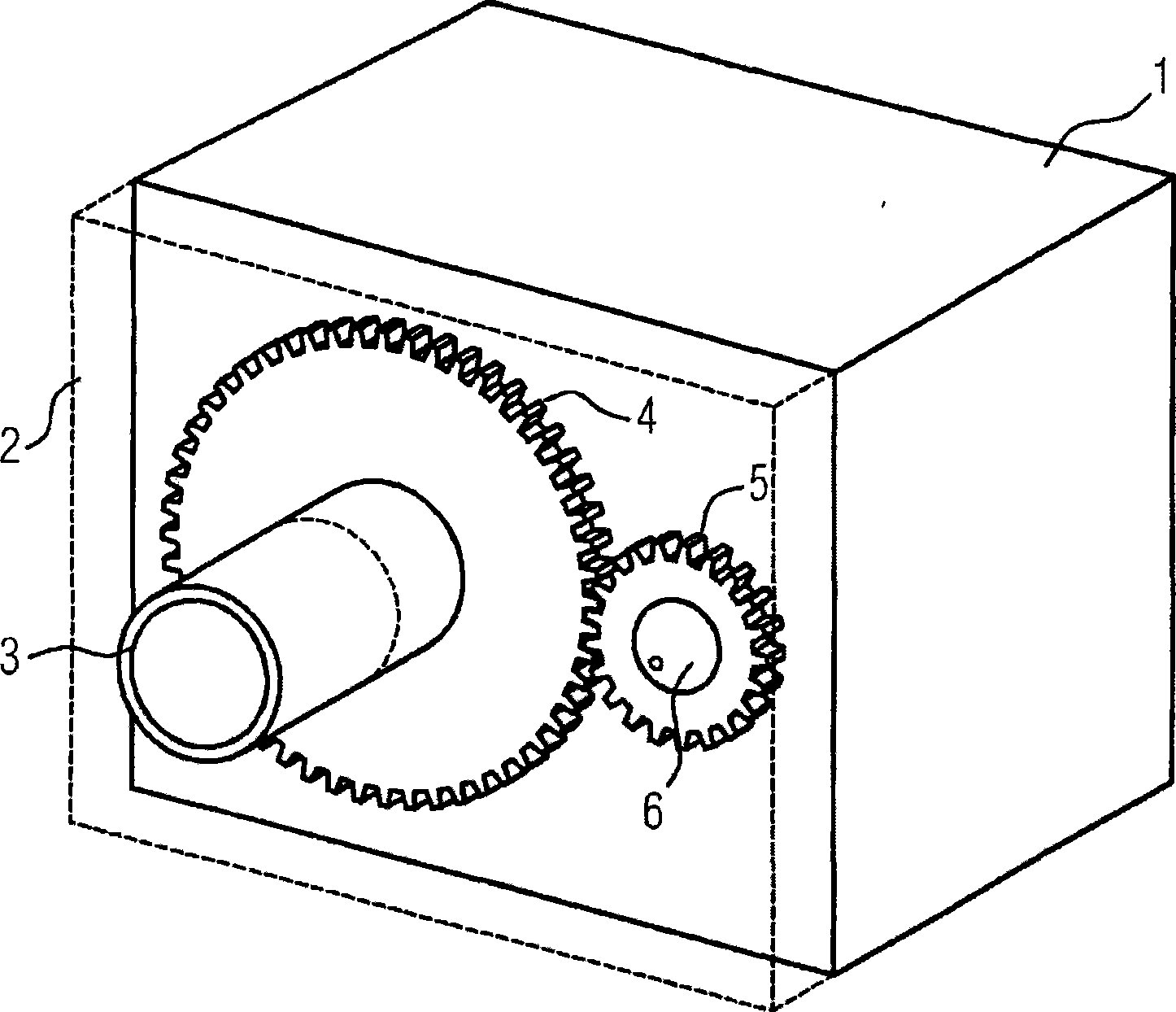

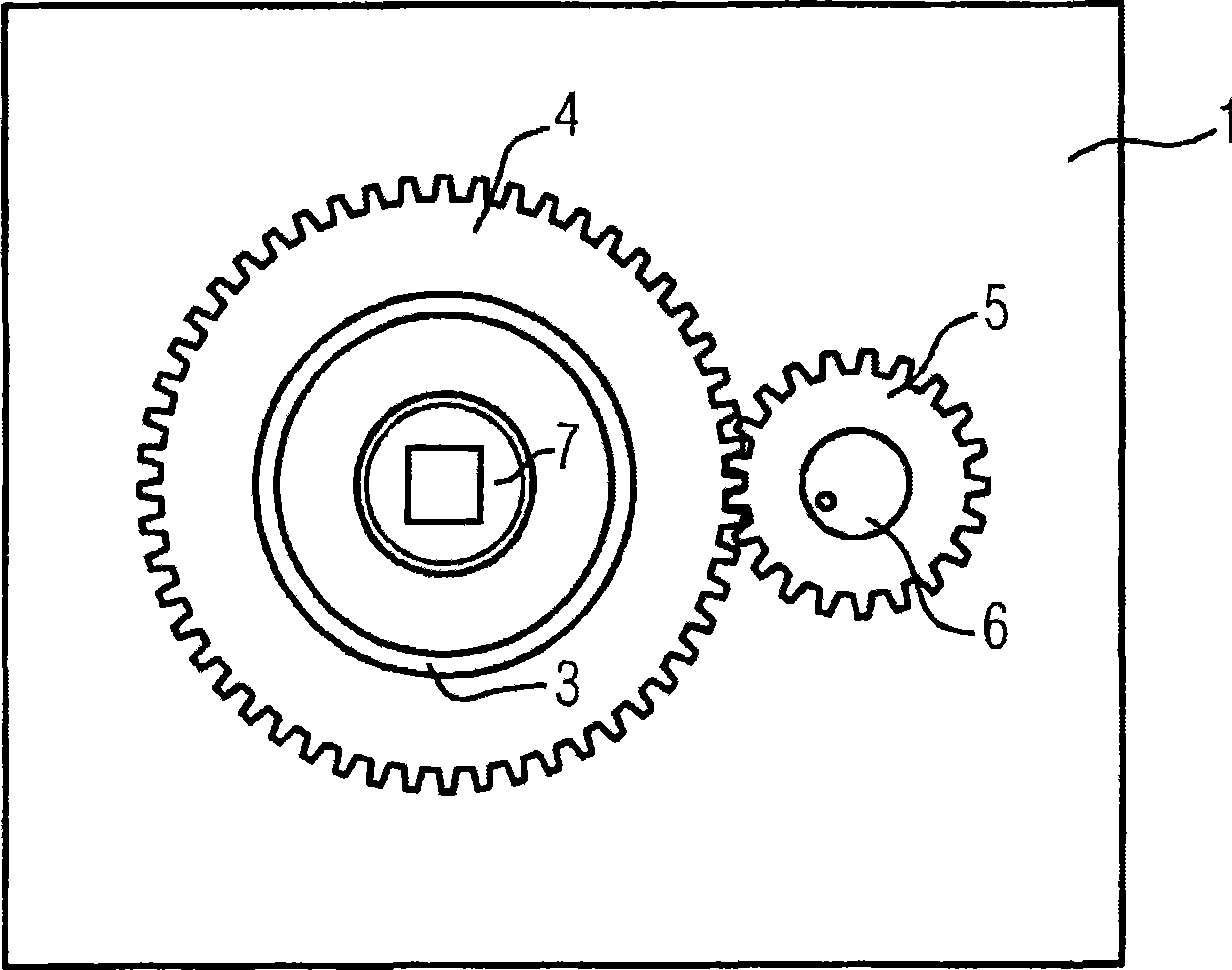

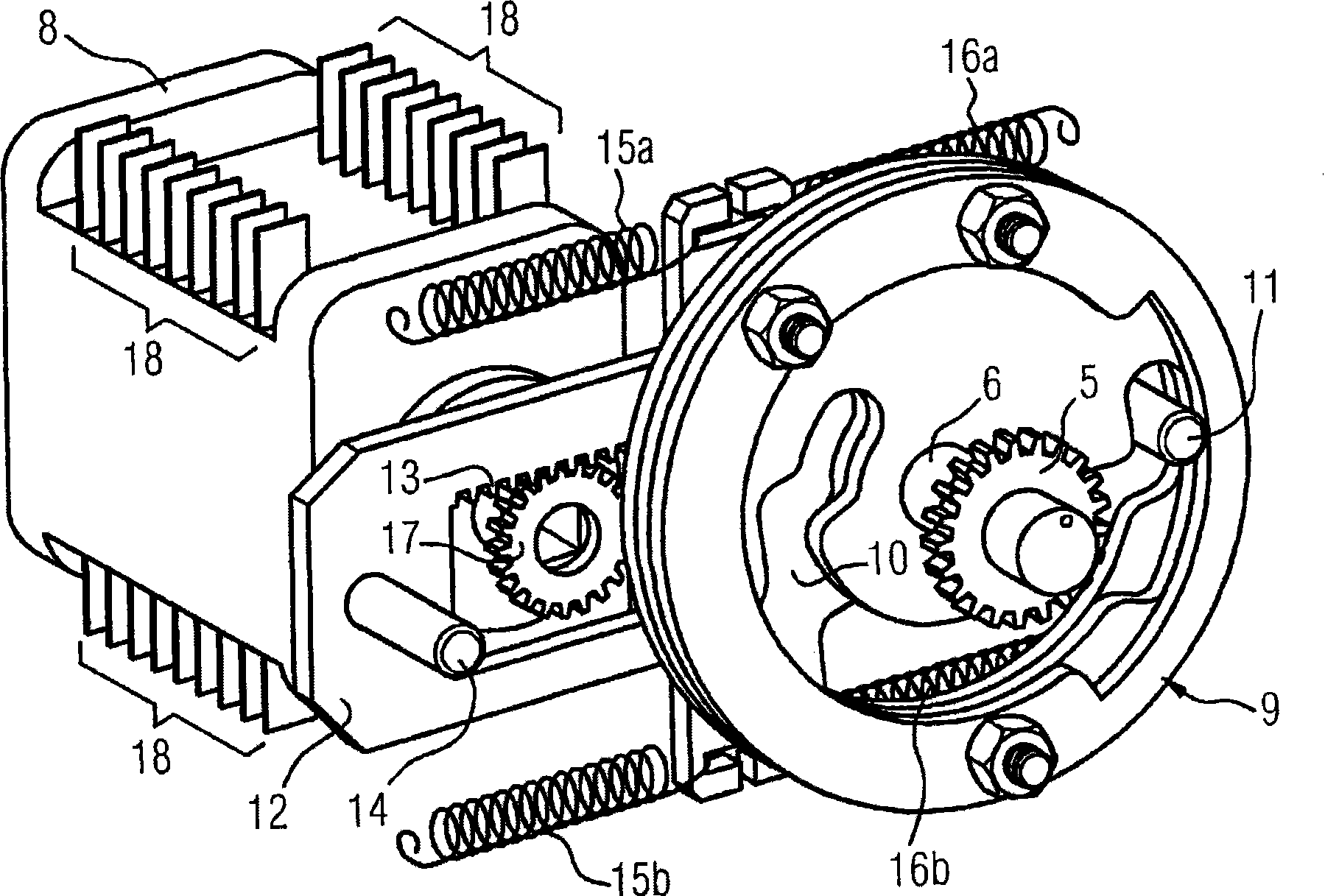

[0040] The transmission device is located inside the frame 1 . The frame basically has a cuboid-shaped structure, and the transmission is installed inside it. To see it more clearly, in figure 1 Middle panel 2 is indicated by a dotted line. A drive shaft 3 protrudes from the panel 2 . The drive shaft 3 is of tubular design and is mounted on the machine frame 1 so as to be rotatable about the longitudinal axis of the tube. The drive shaft gear 4 surrounds the drive shaft 3 concentrically. The drive shaft gear 4 meshes with the drive pinion 5 . The drive pinion 5 is mounted on the drive pinion shaft 6 . Drive shaft gear 4 and drive pinion 5 are covered by panel 2 . In order to interface with the primary distribution equipment, the drive shaft 3 can be directly or indirectly connected to the shaft for driving the primary switch contacts. This is achieved, for example, by the tubular drive shaft 3 being fitted onto the shaft in a positively closed manner.

[0041] figure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com