Developing device, toner particle carrying roller, image forming apparatus, image forming system, and method of manufacturing toner particle carrying roller

A technology for developing devices and image bearing bodies, applied in the fields of electric recording technology using charge patterns, equipment for electric recording technology using charge patterns, and electric recording techniques, which can solve the problem of different concave sizes, depths, shapes, and arrangement methods Uniformity, dispersion, image fog, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 2 approach to no. 4 approach

[0166] [Other Embodiments (Second Embodiment to Fourth Embodiment, etc.)]

[0167] The developing device and the like according to the present invention have been described above based on the above-mentioned embodiments, but the above-mentioned embodiments of the invention are only for making the present invention easier to understand, and are not intended to limit the present invention. The present invention can be changed and improved without departing from the gist thereof, and of course equivalents thereof are also included in the present invention.

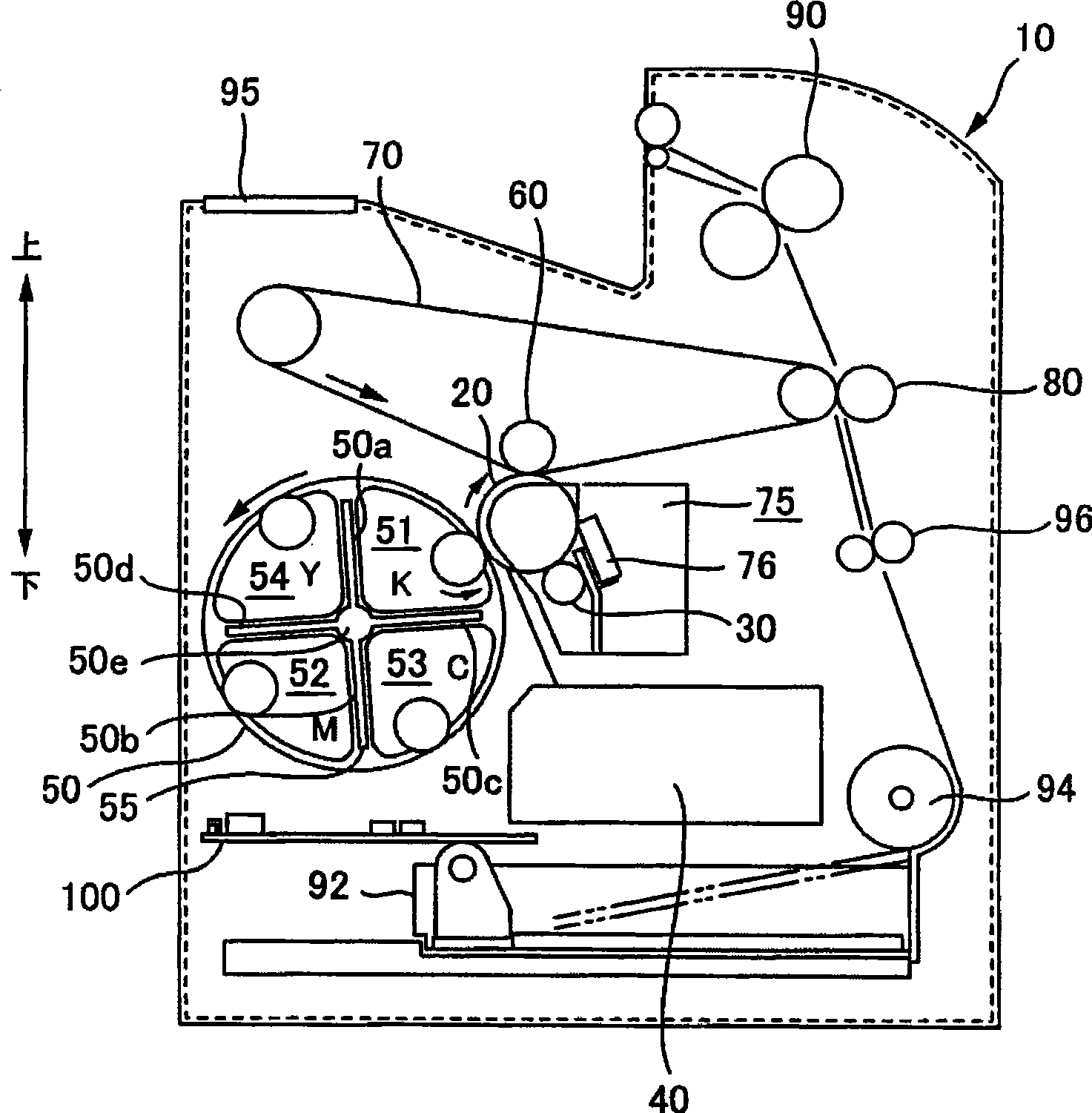

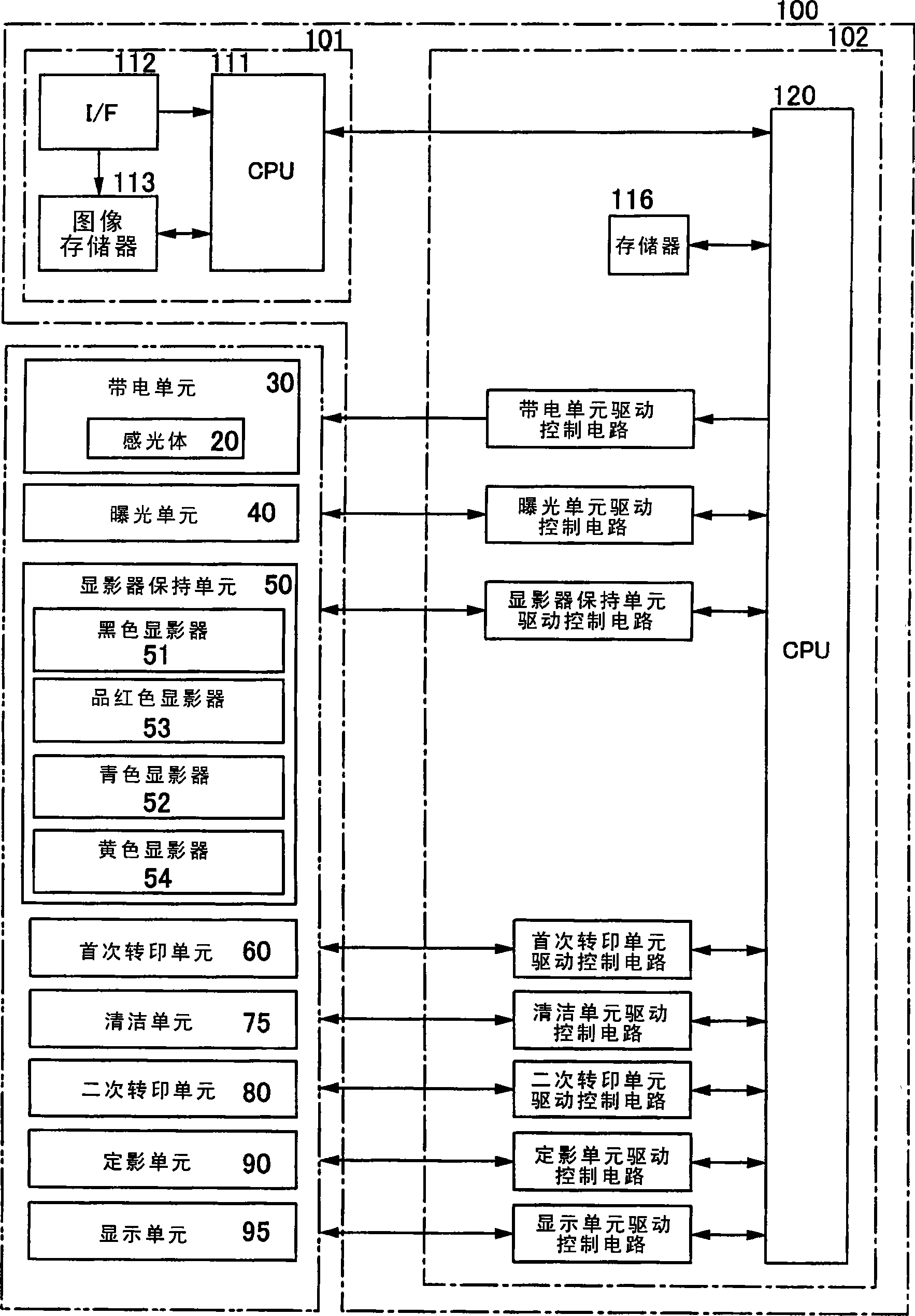

[0168] In the above-mentioned embodiments, an image forming apparatus has been described taking a full-color laser printer as an example, but the present invention can also be applied to various image forming apparatuses such as monochrome laser printers, copiers, and facsimile machines.

[0169] In addition, in the above-mentioned embodiment, the example in which the printer has a plurality of attaching and detachable parts ...

no. 2 approach

[0173] >

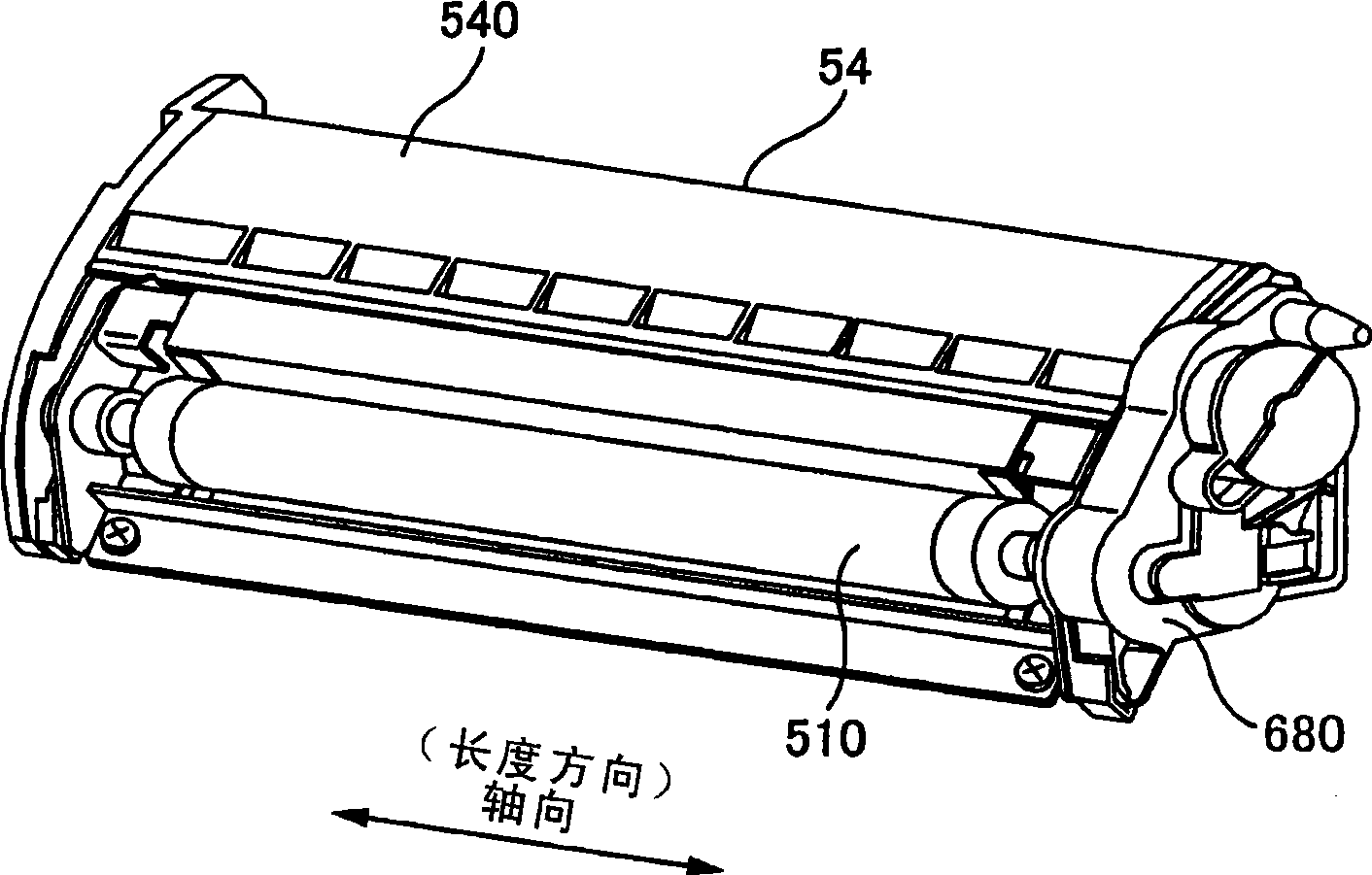

[0174] Here, use Figure 15 to Figure 18 A structural example of the developing roller 510 of the developing device according to the second embodiment will be described. Figure 15 It is a schematic perspective view of the developing roller 510, showing the spiral first groove 1518a and the second groove 1518b whose winding directions are different from each other. Figure 16 It is a schematic front view of the developing roller 510 , showing the positional relationship of the uneven processed portion 1512 , the non-embossed processed portion 1514 , and the intermediate portion 1516 of the developing roller 510 . Figure 17 is a schematic diagram of the cross-sectional shape of the trench 1518 . Figure 18 yes Figure 16 A-A cross-sectional schematic diagram, showing the difference between the depth of the groove 1518 of the concave-convex processing part 1512 and the depth of the groove 1518 of the middle part 1516. exist Figure 15 to Figure 18 In , in order ...

no. 3 approach

[0203] >

[0204] Here, use Figure 19 to Figure 22 A structural example of the developing roller 510 of the developing device according to the third embodiment will be described. Figure 19 It is a schematic perspective view of the developing roller 510, showing the helical first groove 2518a and the second groove 2518b whose winding directions are different from each other. Figure 20 It is a schematic front view of the developing roller 510 , showing the positional relationship between the groove forming portion 2512 and the non-groove forming portion 2514 of the developing roller 510 . Figure 21 is a schematic diagram of the cross-sectional shape of the trench 2518. Figure 22 yes Figure 20 The A-A cross-sectional schematic diagram shows the difference between the depth of the groove 2518 in the central portion 2512a and the depth of the groove 2518 in the two end portions 2512b. In addition, in Figure 19 to Figure 22 In , in order to make the figure easier to unde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com