Electrostatic wax spraying machine

An electrostatic spraying and electrostatic technology, applied in the direction of spraying devices, liquid spraying equipment, etc., can solve the problems of inconsistent bending strength, affecting product processing quality, affecting product stamping quality, etc., to reduce manpower operations, improve raw material waste and not Uniformity, the effect of improving the electrification degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below in conjunction with the embodiments and the accompanying drawings, but the embodiments of the present invention are not limited thereto.

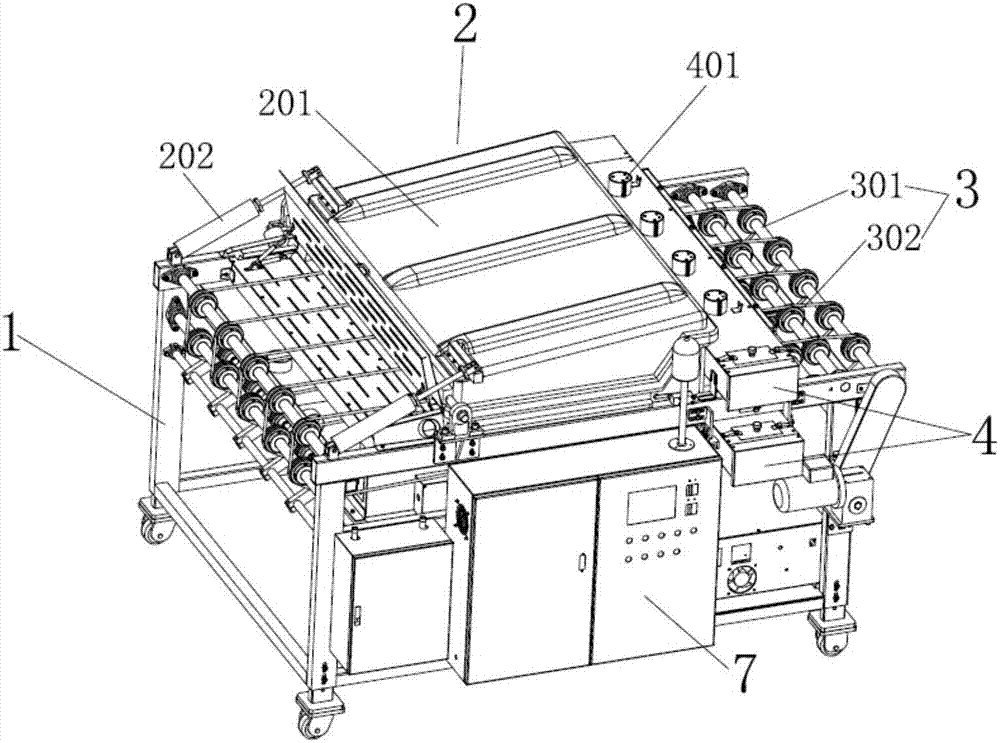

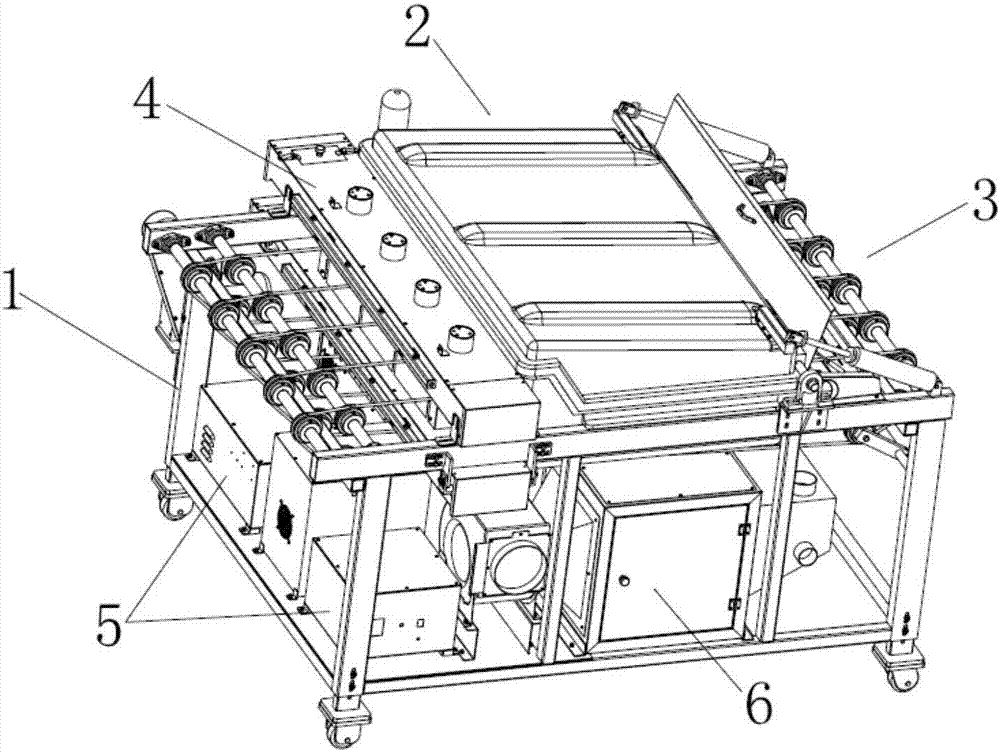

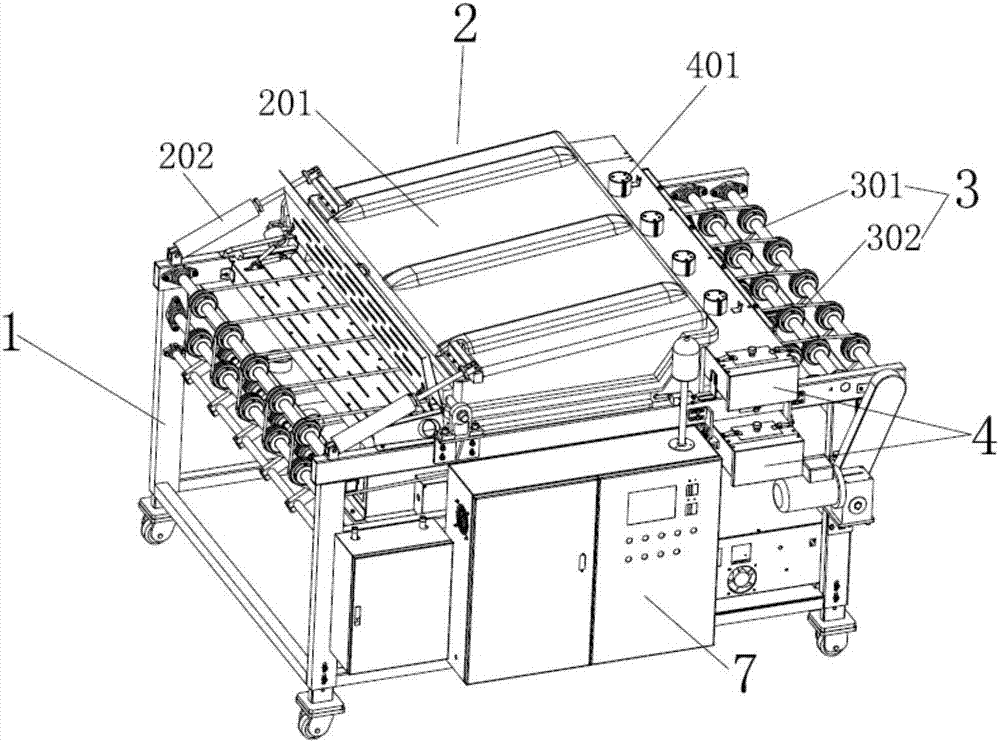

[0020] Such as Figure 1 to Figure 2 As shown, the electrostatic wax spraying machine includes a working support 1, an electrostatic adsorption box 2 arranged on the working support 1, and a conveying mechanism 3 provided through the electrostatic adsorption box 2, and the conveying mechanism 3 includes a conveying roller 301 and a connection On the conveyor belt 302 between the conveyor rollers 301, the upper and lower sides of the conveyor roller 301 are provided with a wax melting box 4, and the wax melting box 4 is provided with a nozzle module 401, and the nozzle module 401 includes a super A fine atomizing nozzle and a spray volume controller connected between the wax melting box 4 and the ultrafine atomizing nozzle, the electrostatic adsorption box 2 is provided w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com