Roller for taking up and/or transferring glue in devices of the tobacco processing industry

A processing industry and equipment technology, which is applied in the direction of tobacco, cigarette manufacturing, and liquid coating device on the surface, etc. It can solve the problems of difficult handling, insufficient strength and compressive stability, roll weight, etc., and achieve high sealing, The effect of enriching diversity and reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

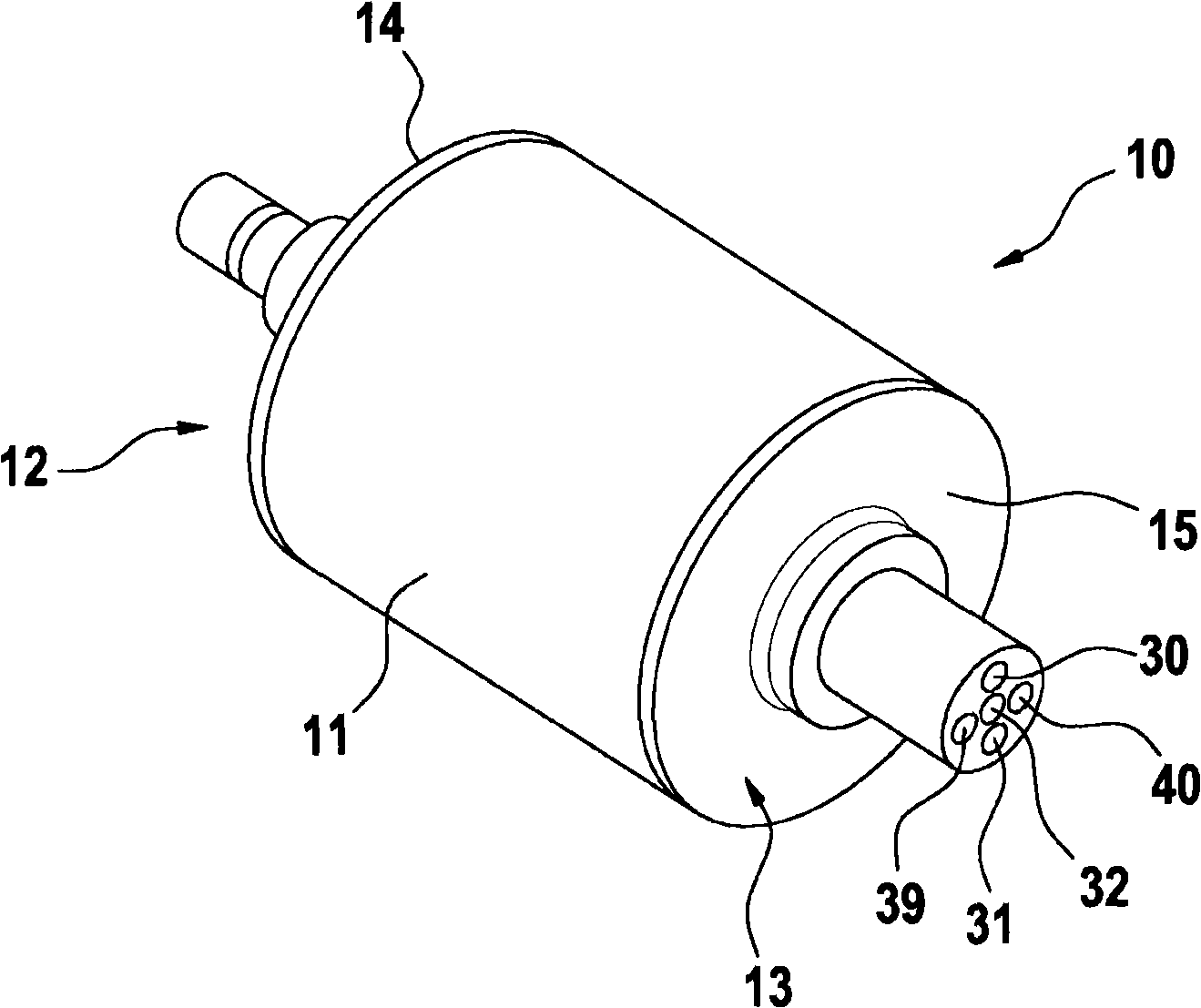

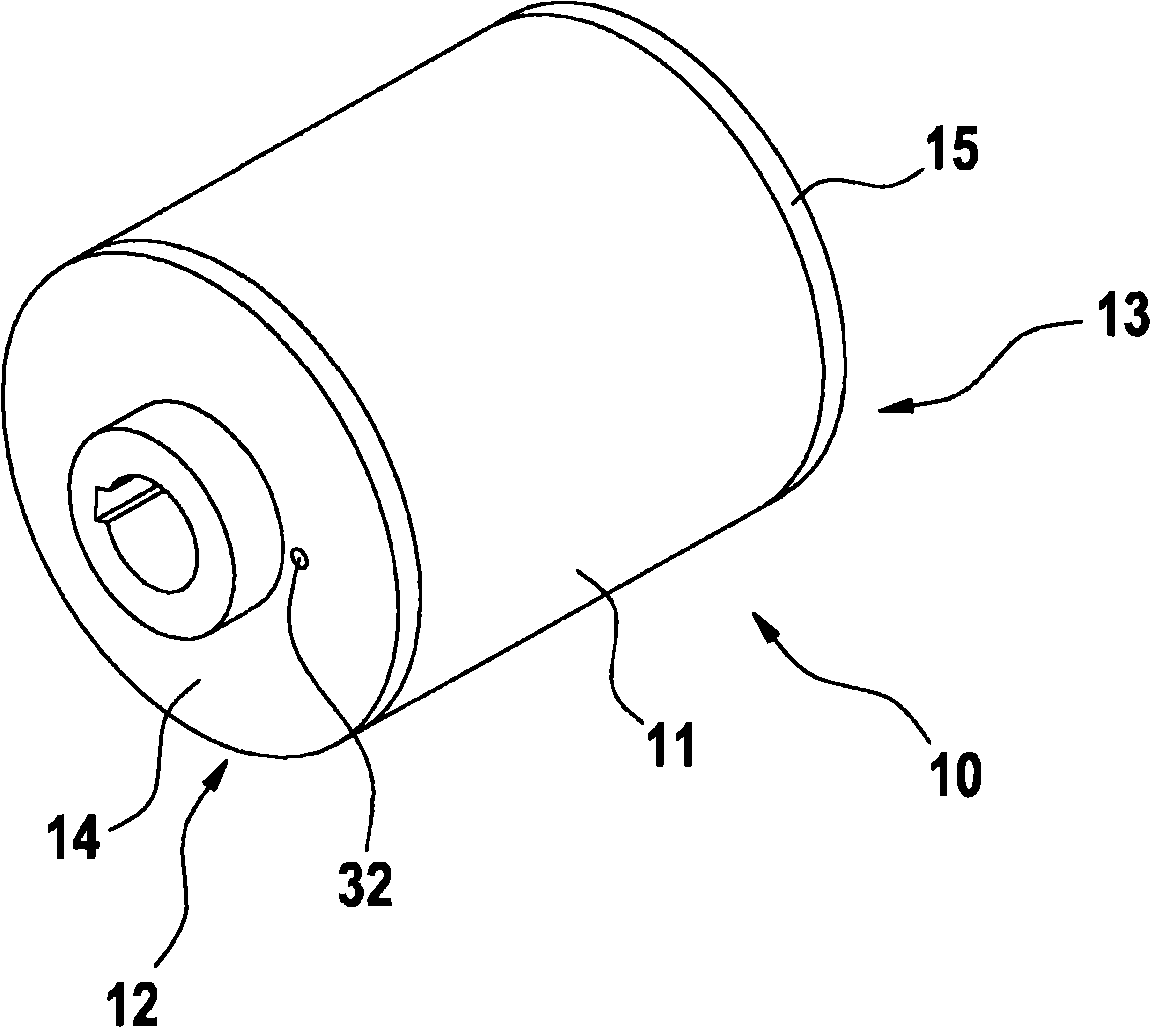

[0018] The rollers shown are used to pick up and / or transfer glue in equipment used to manufacture cigarettes and the like.

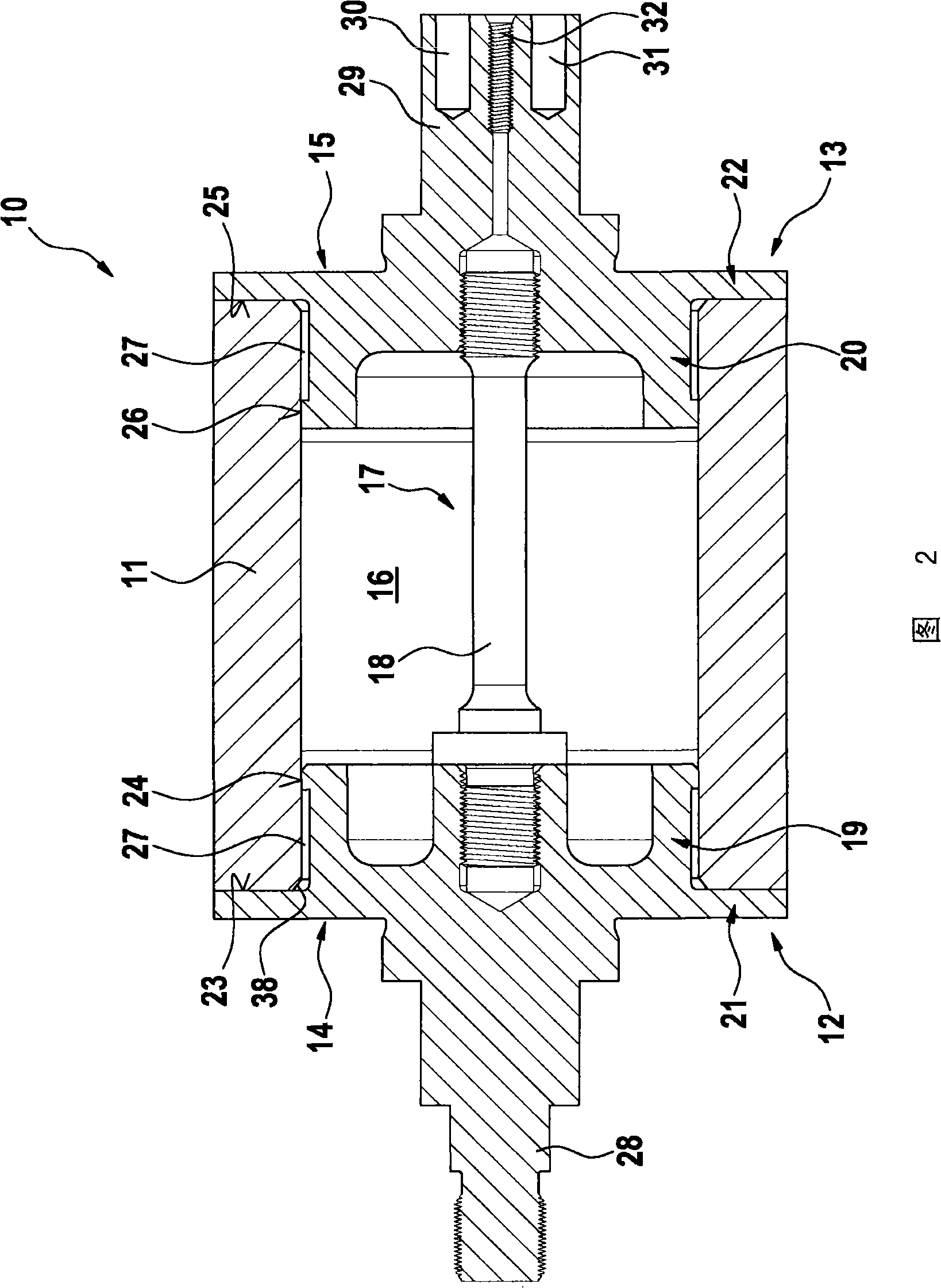

[0019] figure 1 with figure 2 The roller 10 shown comprises a cylindrical hollow-body-shaped base body 11 . A round tubular structure is preferred. However, it is also possible in principle for the cross-section of the base body 11 to have a non-cylindrical shape. The base body 11 is each provided with a flange element 14 or 15 on two opposite end faces 12 and 13 . Each flange element 14 or 15 is preferably formed in one piece. The two flange elements 14 and 15 facing one another form the cavity 16 together with the base body 11 , which are coupled to one another via a coupling piece 17 . The coupling between the flange elements 14 , 15 and the base body 11 is achieved by bonding. In the assembled state, the roller 10 is an inseparable sealed unit.

[0020] The coupling part 17 is designed in the form of a tie rod 18 . In other words, the flang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com