System and method for testing stress, displacement and airtight performance in ultra-low temperature surroundings

A technology of environmental stress and testing system, applied in the direction of using liquid/vacuum for liquid tightness measurement, force measurement, measurement device, etc., can solve problems such as restricting the development of sealing research and lack of testing means.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

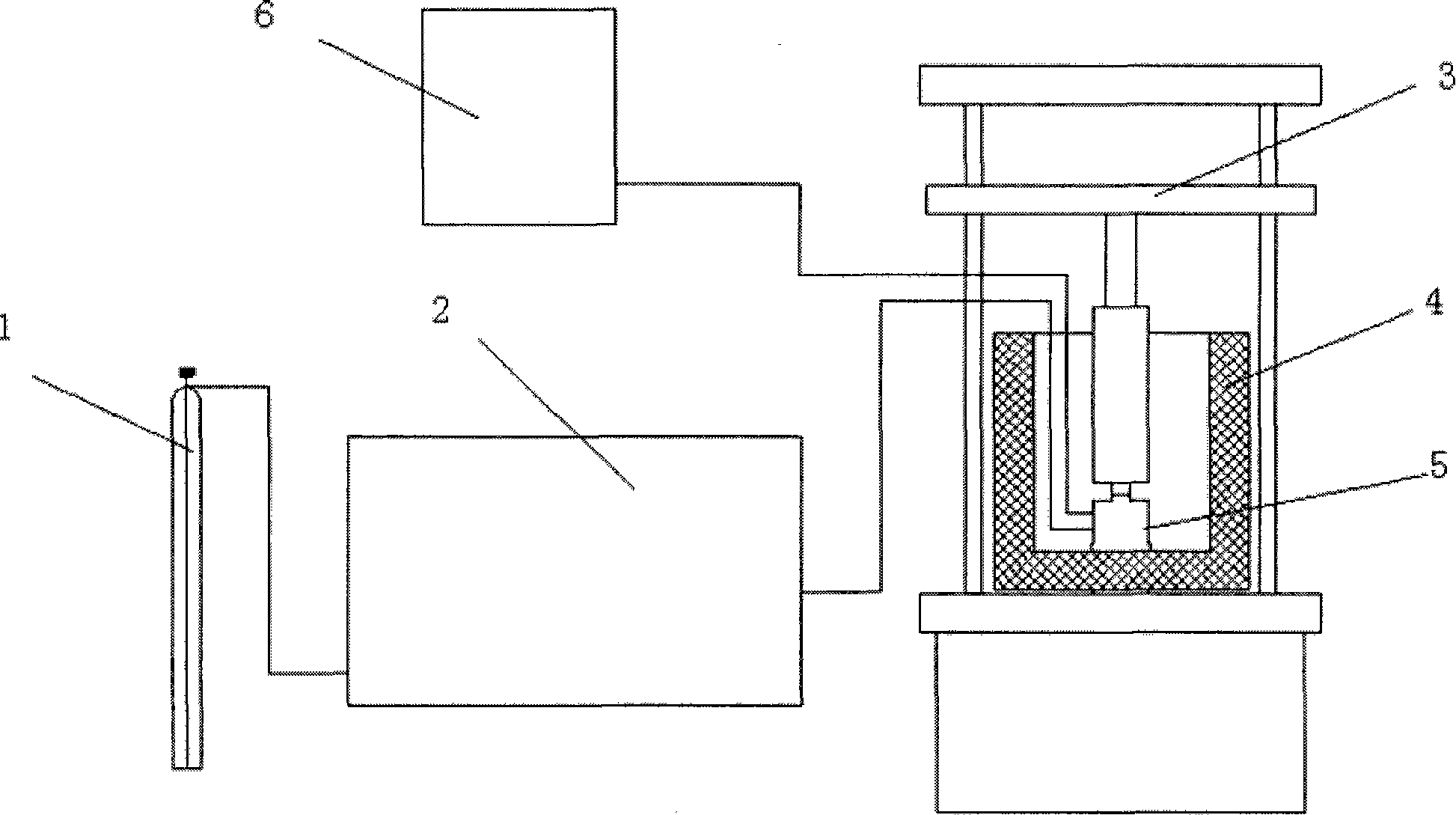

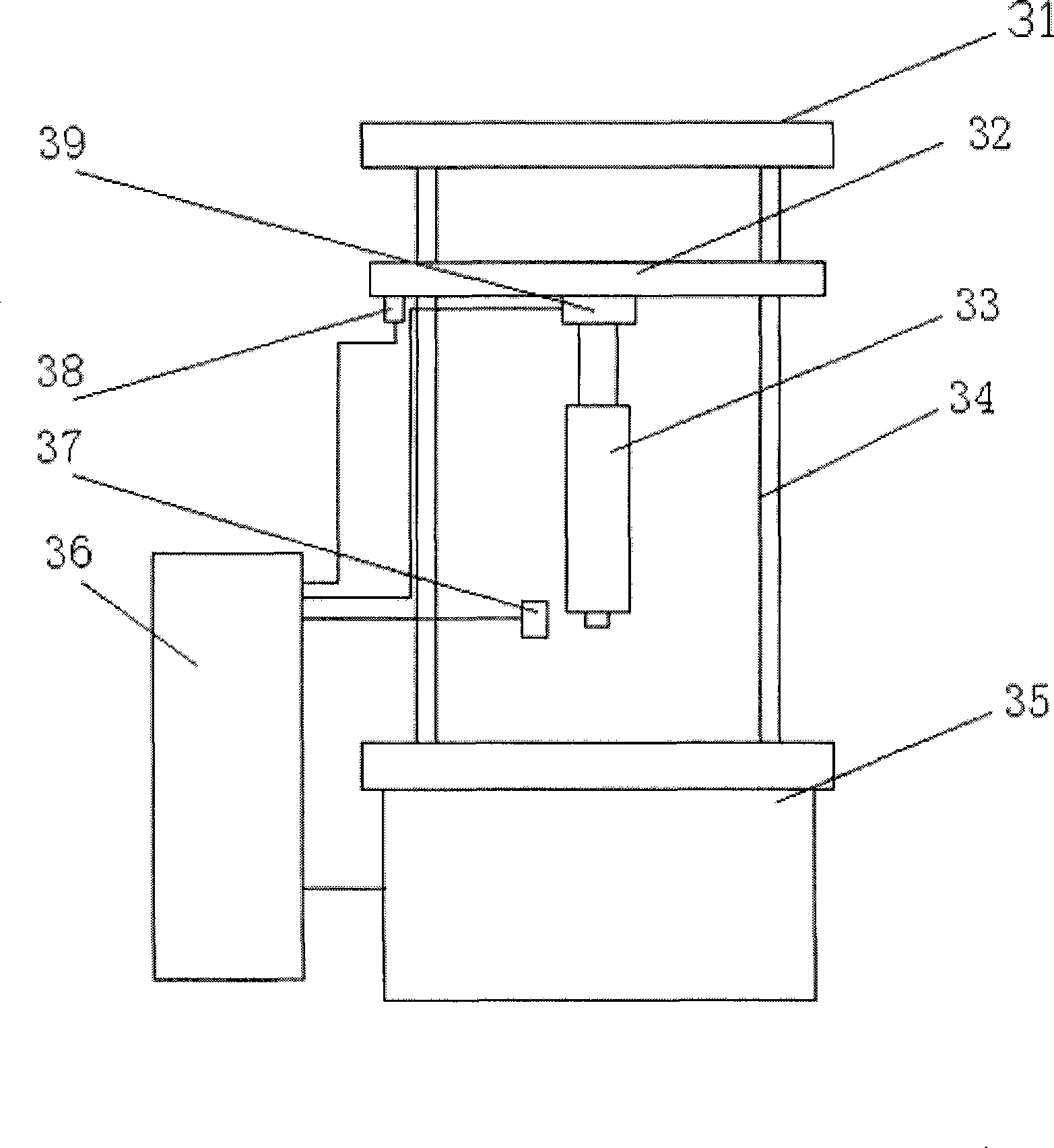

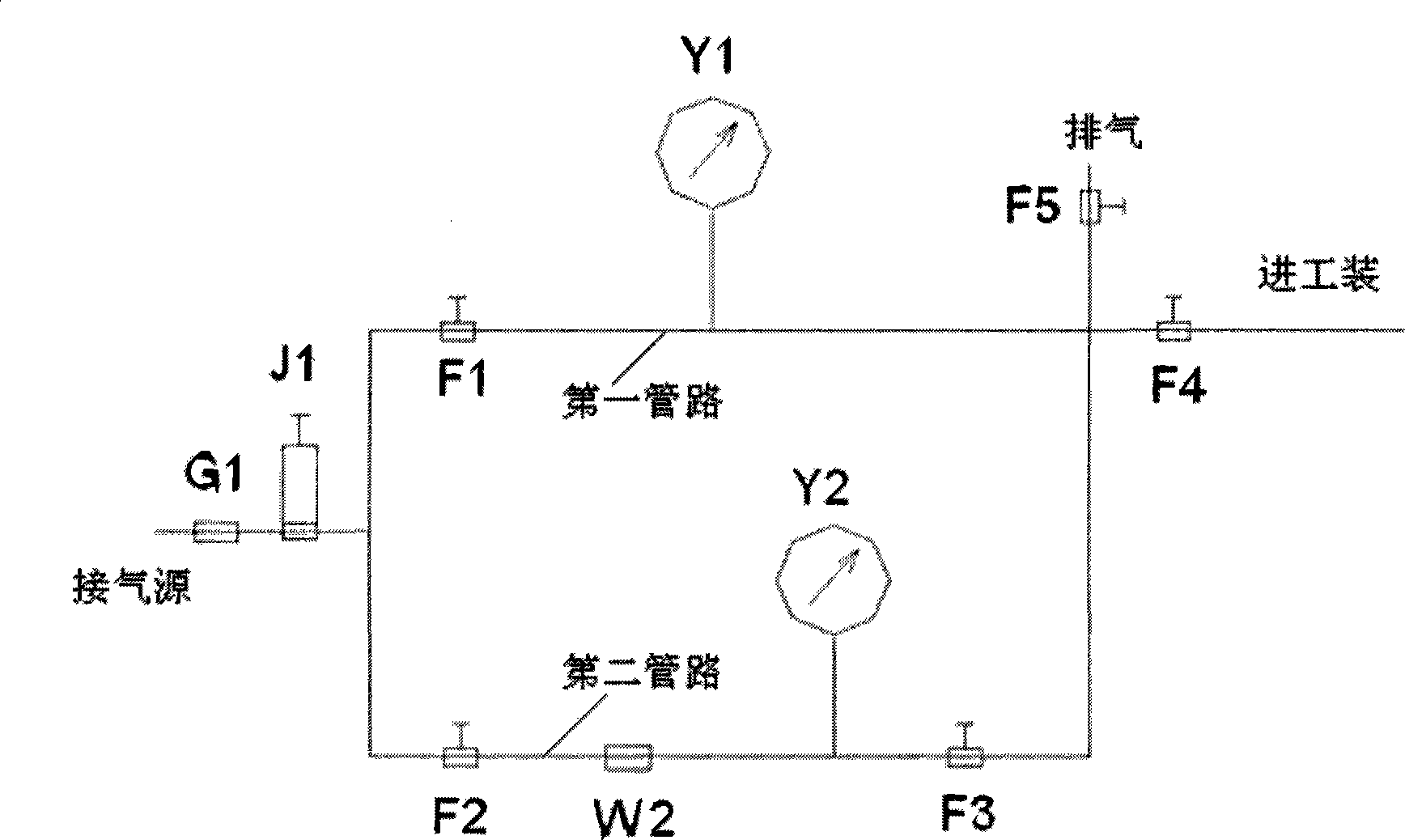

[0029] Such as figure 1 As shown, the test system for stress displacement and airtight performance in ultra-low temperature environment includes air source 1, working pressure control system 2, sealing load loading system 3, temperature environment guarantee system 4, sealing leak detection system 6, air source 1 and working pressure The control system 2 is connected through the air pipe; the working pressure control system 2 is connected to the medium input port of the sealing test tool 5 through the air pipe, and the sealing leak detection system 6 is connected to the leak detection port of the sealing test tool 5 through the air pipe, and the sealing test tool 5 is placed at temperature In the environment guarantee system 4 , the temperature environment guarantee system 4 is placed on the workbench of the sealed load loading system 3 .

[0030] The gas source 1 can be the direct pressure working medium provided by the gas cylinder, or the pressure working medium indirectly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com