Lightweight structured suitcase

A luggage and component technology, applied in the field of light luggage, can solve the problems of being easily torn and unable to effectively protect items

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

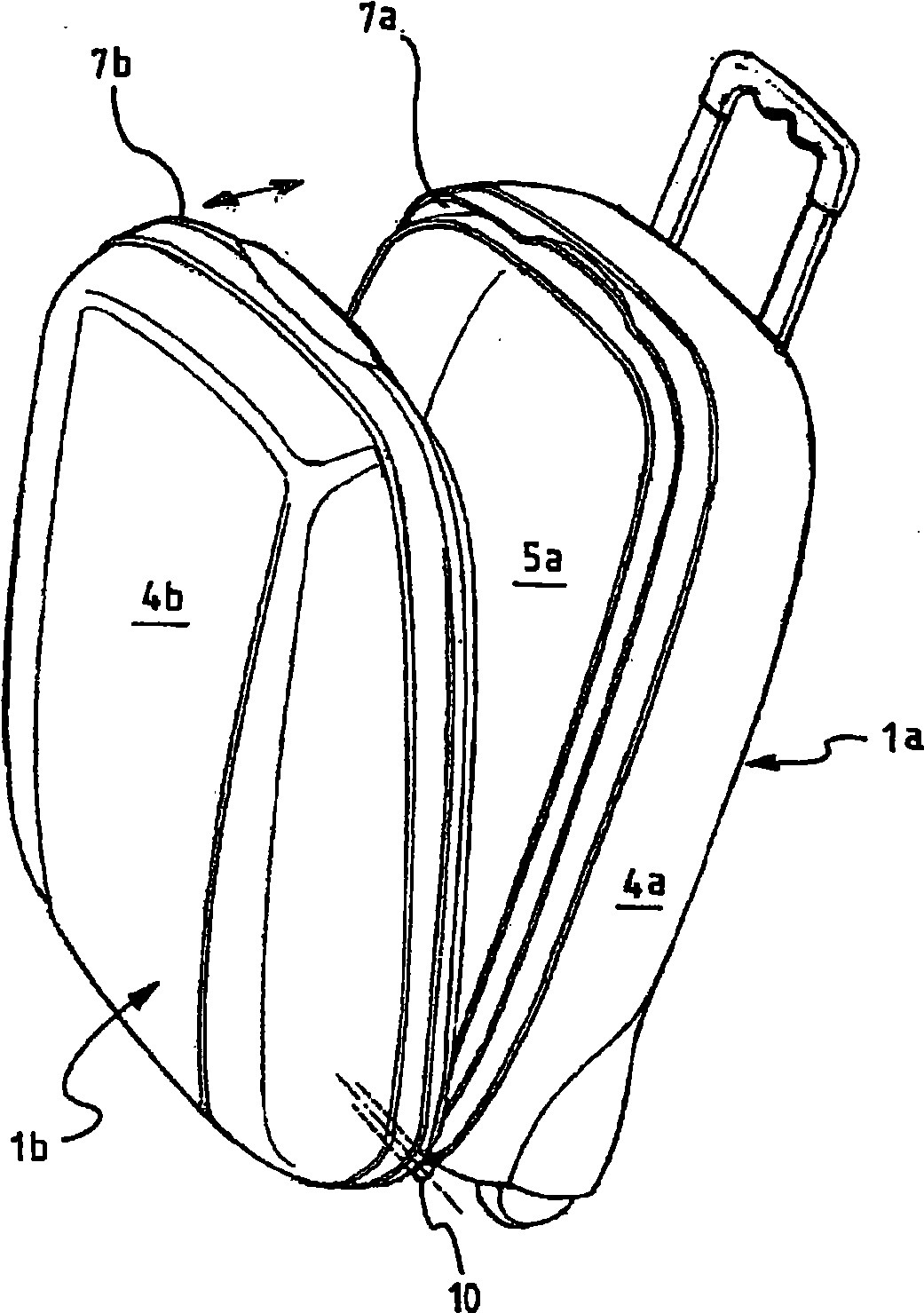

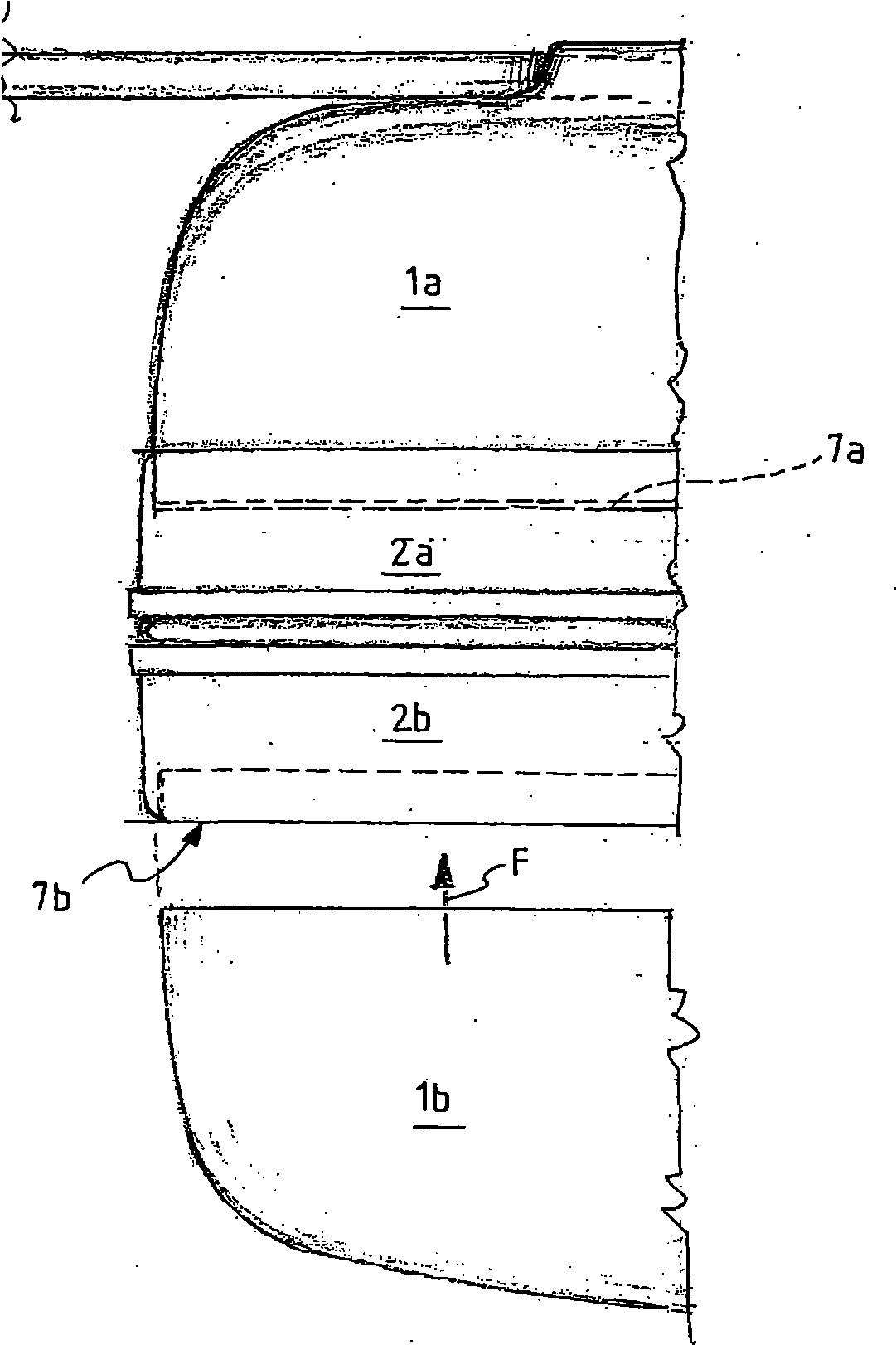

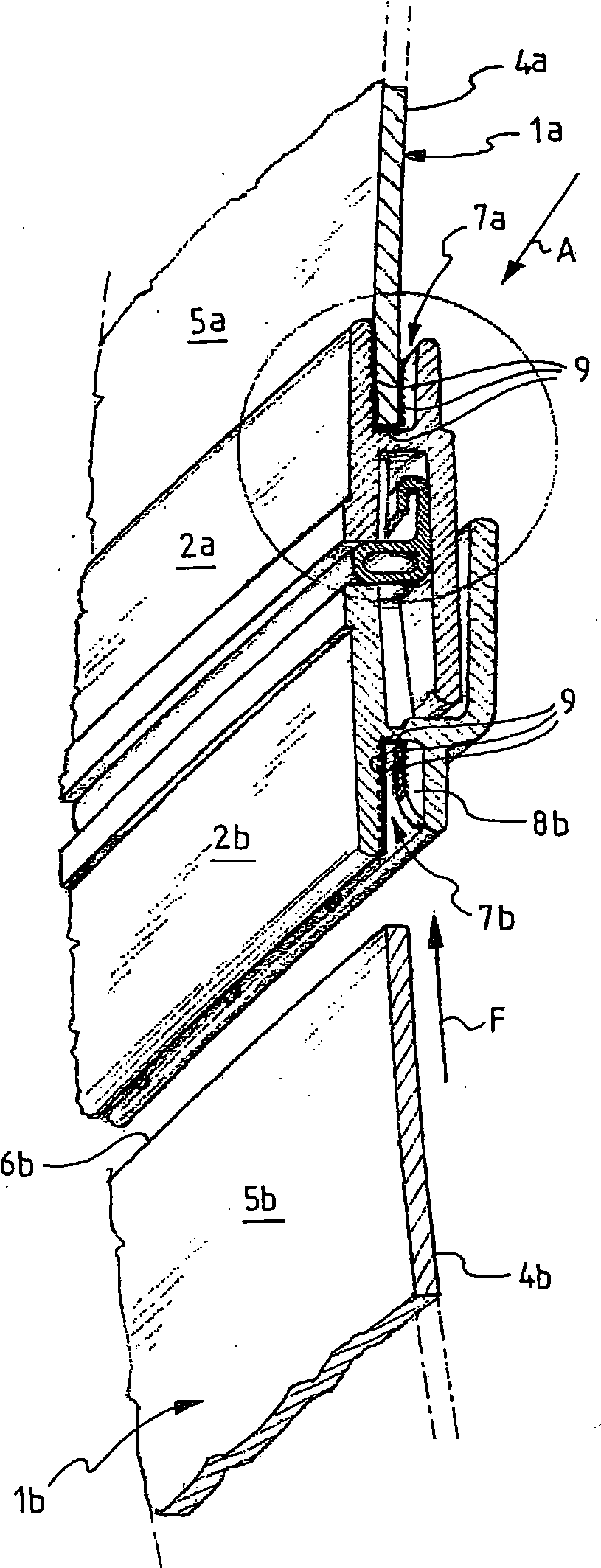

[0018] Such as figure 1 The shown luggage case comprises two components 1a, 2a between which at least partly an adhesive material 3 is firmly connected by bonding.

[0019] These two components 1a, 2a are preferably an outer shell 1a and a reinforcement frame 2a made of polymeric material, but obviously these two components 1a, 2a can be any two components on a luggage case that must be firmly connected together.

[0020] For example, the connection between attachments or accessories such as handles, locks, hinges and the trunk frame can be bonded.

[0021] In a preferred embodiment, at least one of the two components 1a, 2a joined together by the bonding material 3 is made of thermoplastic material, eg PC, PC / ABS, PP, HDPE.

[0022] Each of the two housings 1a, 1b, preferably stamped or injection molded from sheet metal, has a raised outer surface 4a, 4b visible from the outside, as well as an opposite inner surface 5a, 5b and a closed-loop peripheral surface 6a, 6b .

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com