Coffee capsule making device

A technology of coffee capsules and capsule machines, which is applied in kitchen utensils, household utensils, beverage preparation devices, etc., can solve problems such as difficult to meet user requirements, high production costs, troublesome operation, etc., and achieve simple and reasonable structure, high safety, reliable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

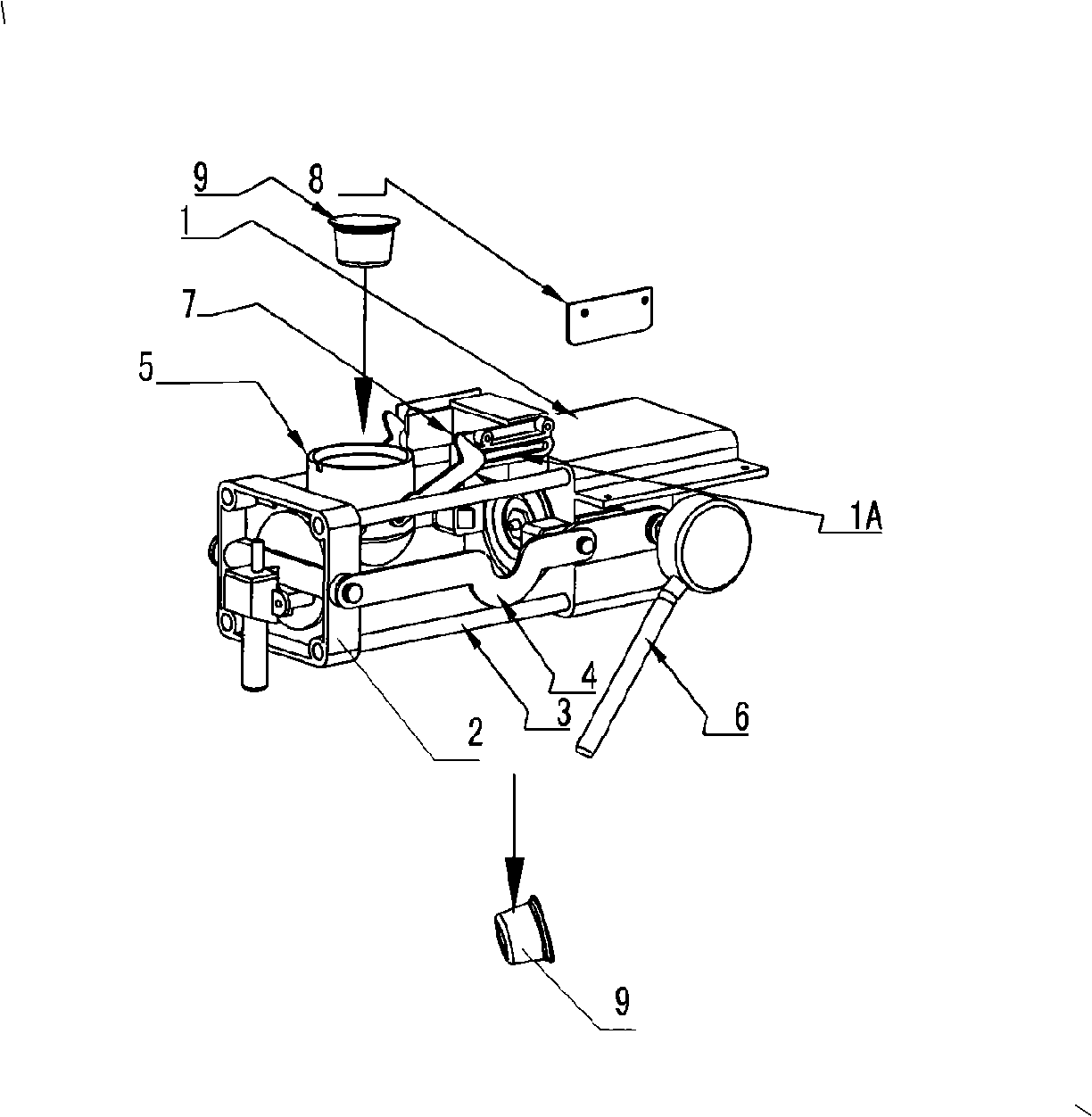

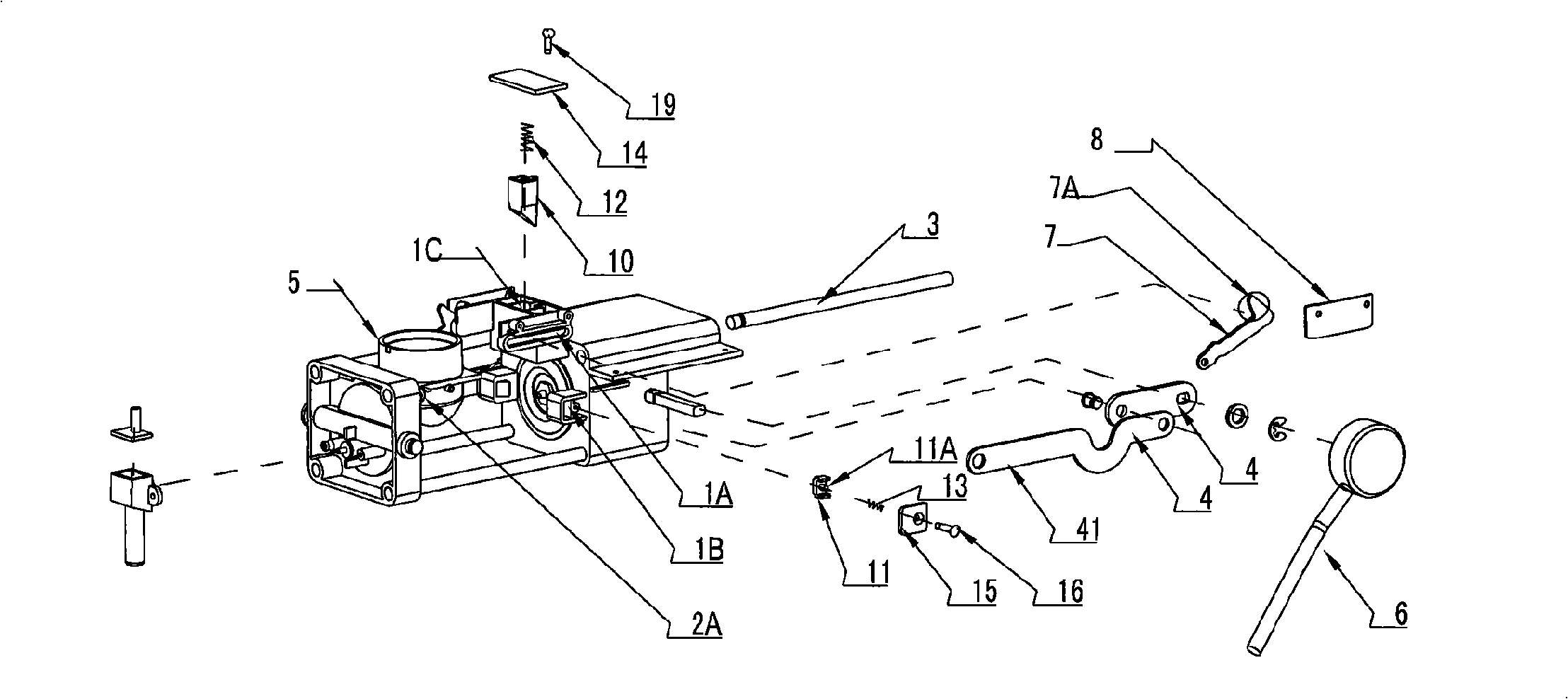

[0032] The schematic diagram of the structure of the present invention is shown in Figures 1 and 2, including a brewing device A arranged in the body 18, wherein the brewing device A includes a water inlet assembly 1, an outlet assembly 2, and a device for driving the outlet assembly 2 to perform linear motion. The driving mechanism 4, the brewing chamber 5 loaded with the coffee capsule 9, and the connecting rod 7, wherein the water inlet component 1 is provided with a guide rail groove 1A, the follower of the driving mechanism 4 is connected with the water outlet component 2, and one end of the brewing chamber 5 passes through The connecting fulcrum 2A is connected to the water outlet assembly 2, the other end of the connecting rod 7 is connected to the brewing chamber 5, and the connecting rod 7 is equipped with a positioning piece 7A, and the positioning piece 7A is placed on the guide rail groove 1A provided by the water inlet assembly 1. And when the positioning piece 7A ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com