Frost resistant container for extinguishing fluid

A liquid and storage container technology, applied in the field of pressure bottle closure devices, can solve the problems of poor fire resistance, pipeline melting, high purchase cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

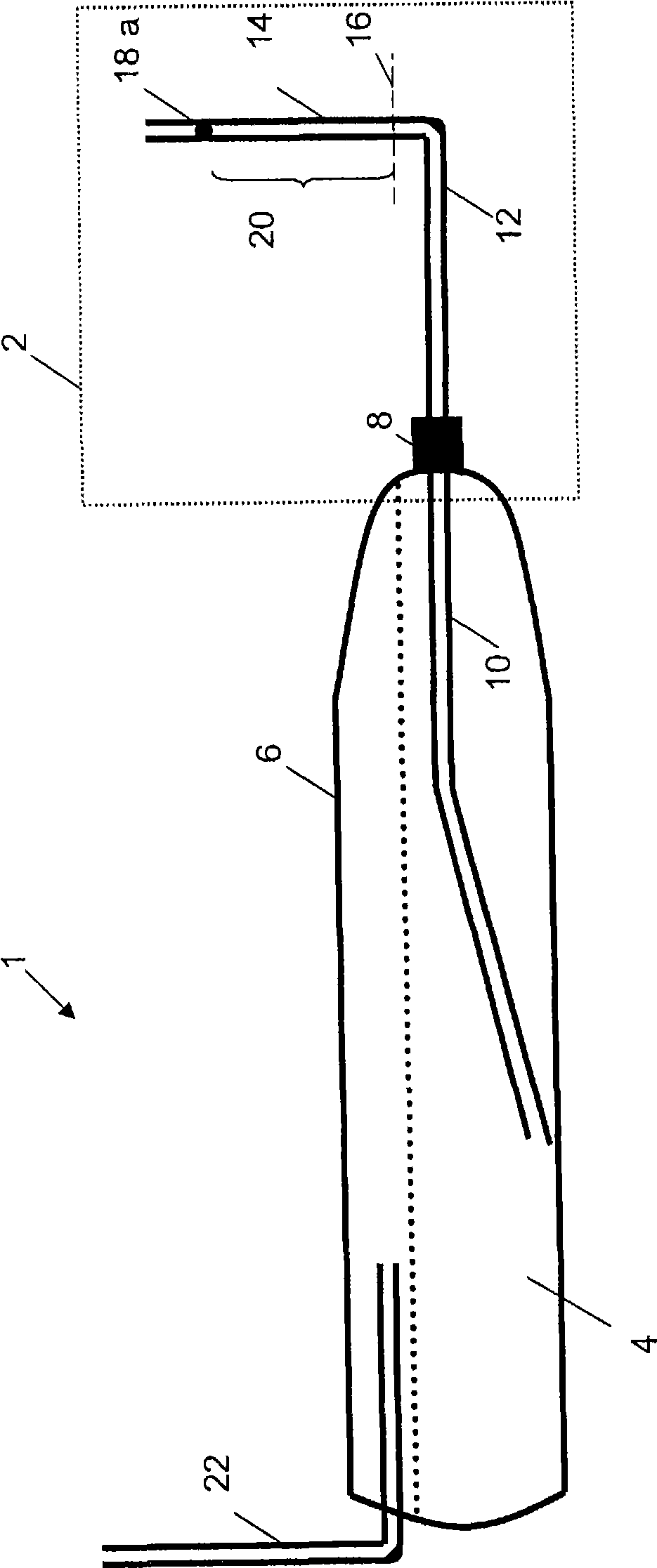

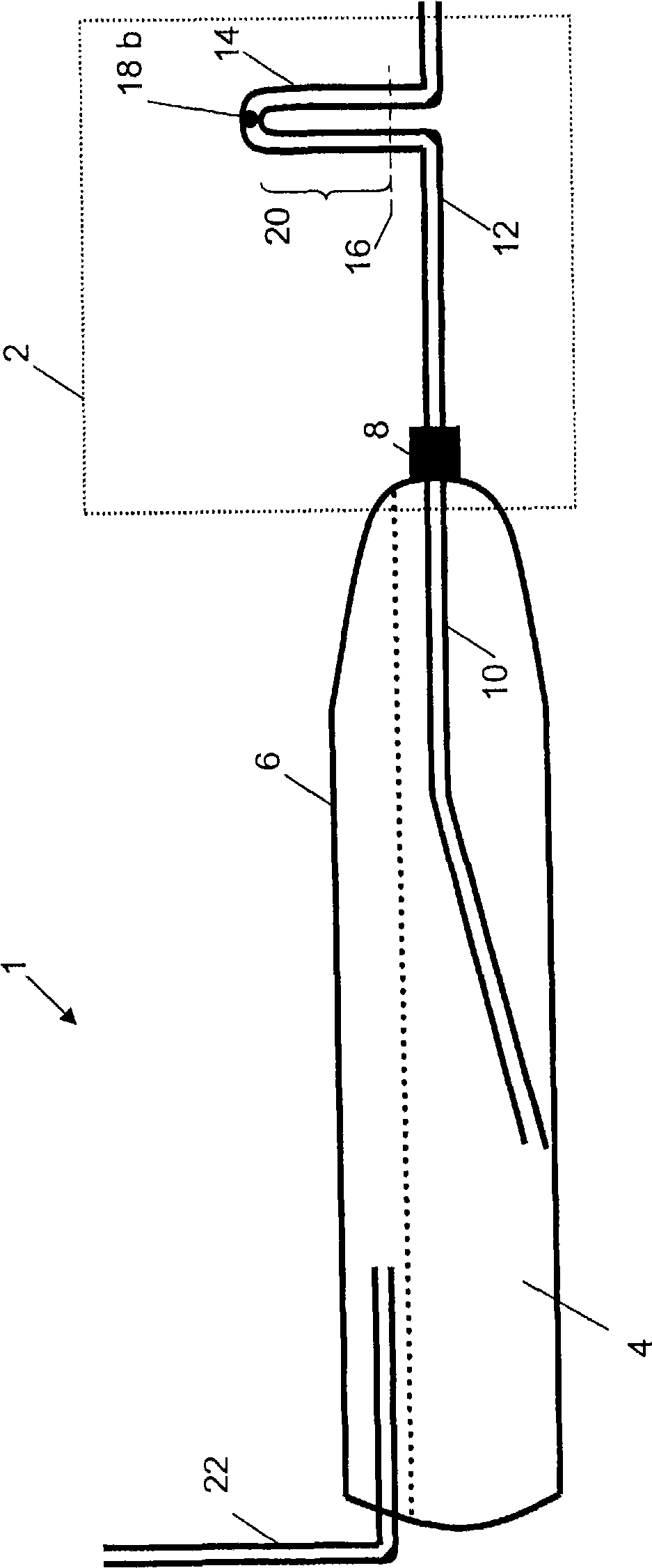

[0024] figure 1 A fire extinguishing device 1 is shown, which comprises a closure device 2 and a pressure bottle 6 . The closure device 2 is composed of an adapter part 8 , a connection part 12 , a standpipe 14 and a rupture disc 18 a. A submerged tube 10 inclined toward the inner wall of the pressure bottle 6 is provided inside the pressure bottle 6 . This submerged pipe 10 is located below the level of the extinguishing liquid 4 . In case of fire, compressed air is introduced into the pressure bottle 6 through the compressed air applying device 22 provided with a one-way check valve (not shown), and the fire extinguishing liquid is sprayed out from the pressure bottle 6 .

[0025] The closure device 2 is formed in such a way that the standpipe 14 bends, preferably perpendicularly, from the connecting piece 12 into the vertical. The rupture disc 18 a is arranged in the standpipe 14 such that the rupture disc is above the level 16 of the extinguishing liquid 14 . A gas spa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com