Exhaust device for engine

A technology for exhaust devices and mufflers, which can be used in exhaust devices, machines/engines, noise reduction devices, etc., and can solve expensive and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

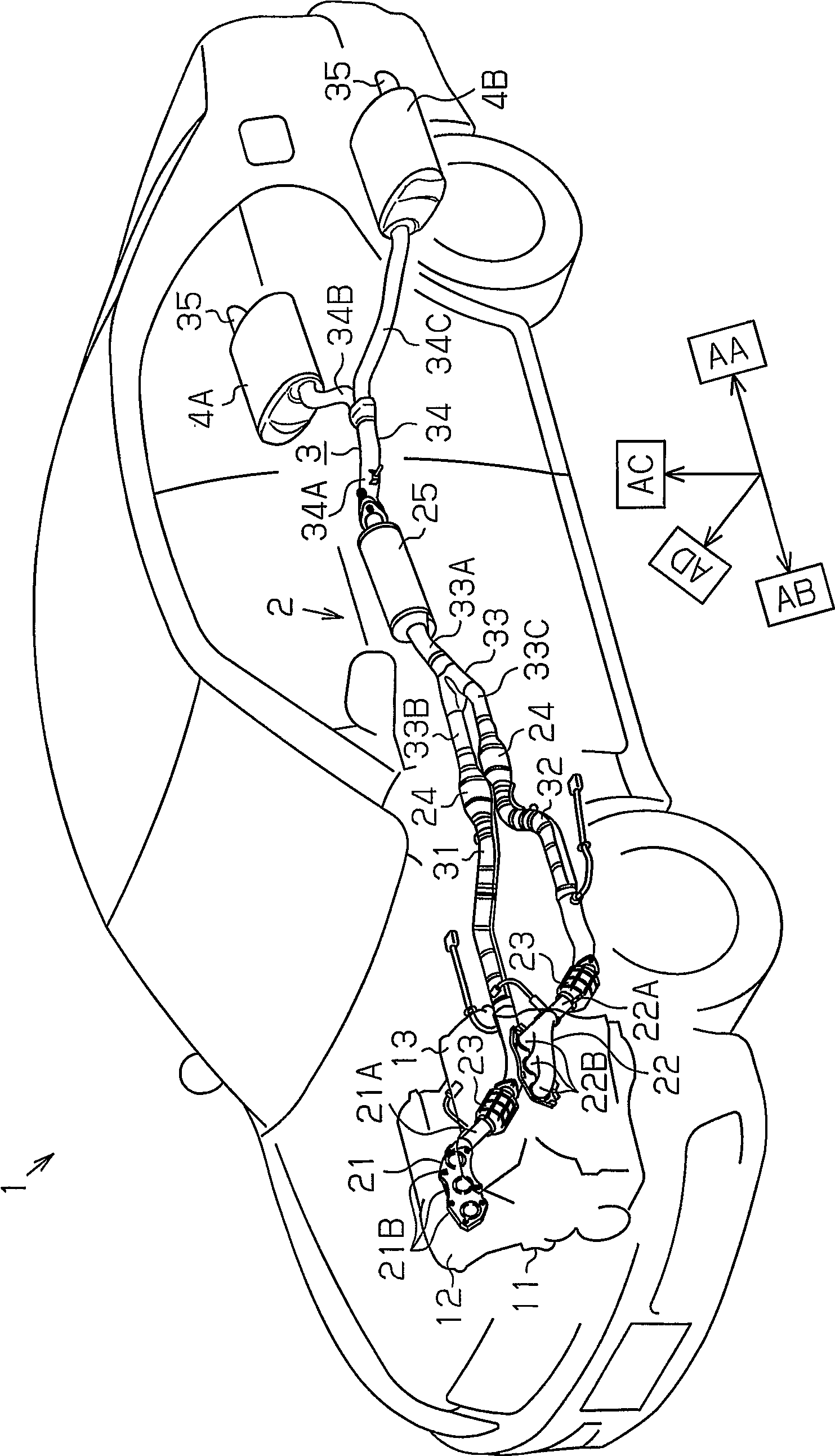

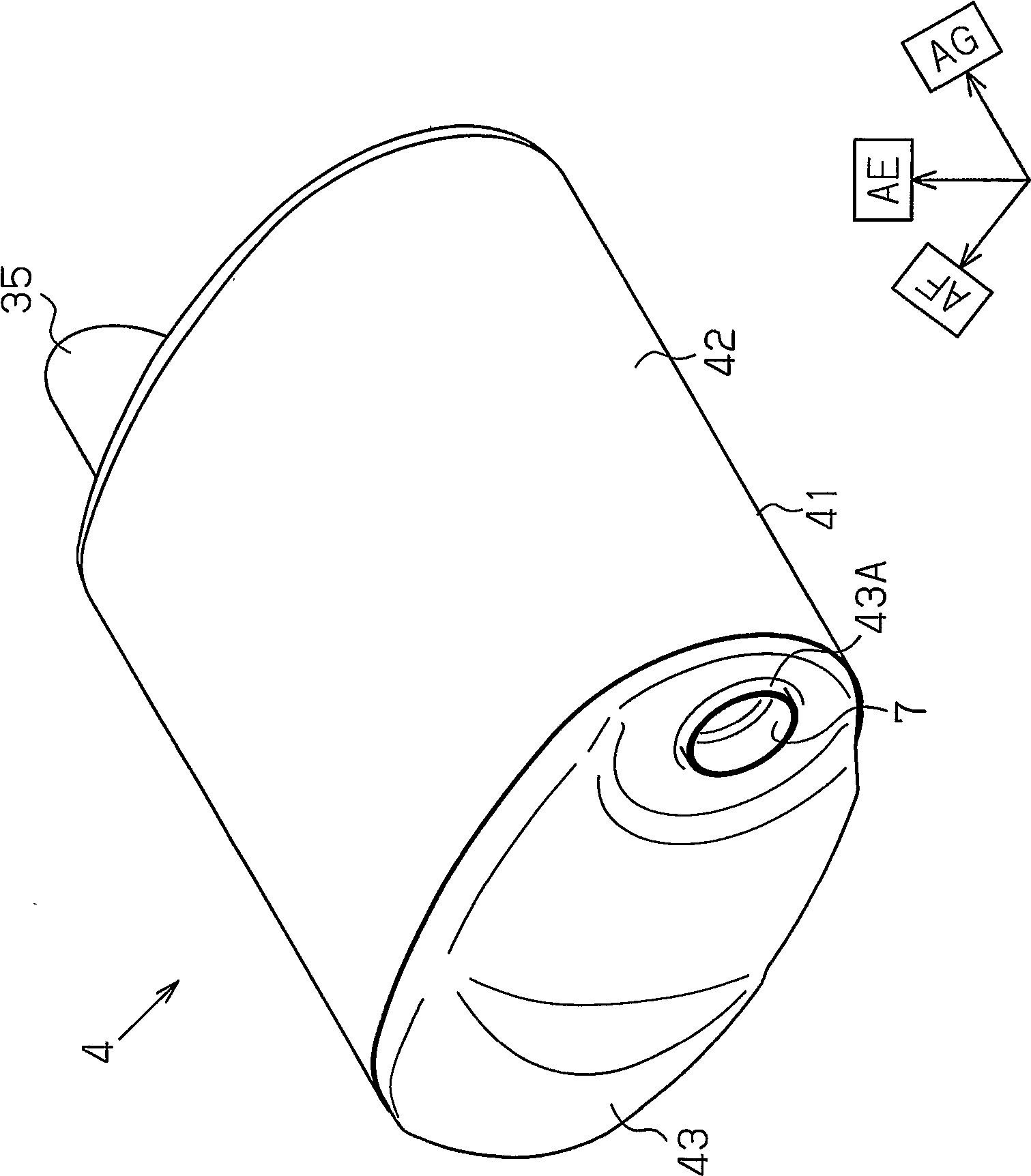

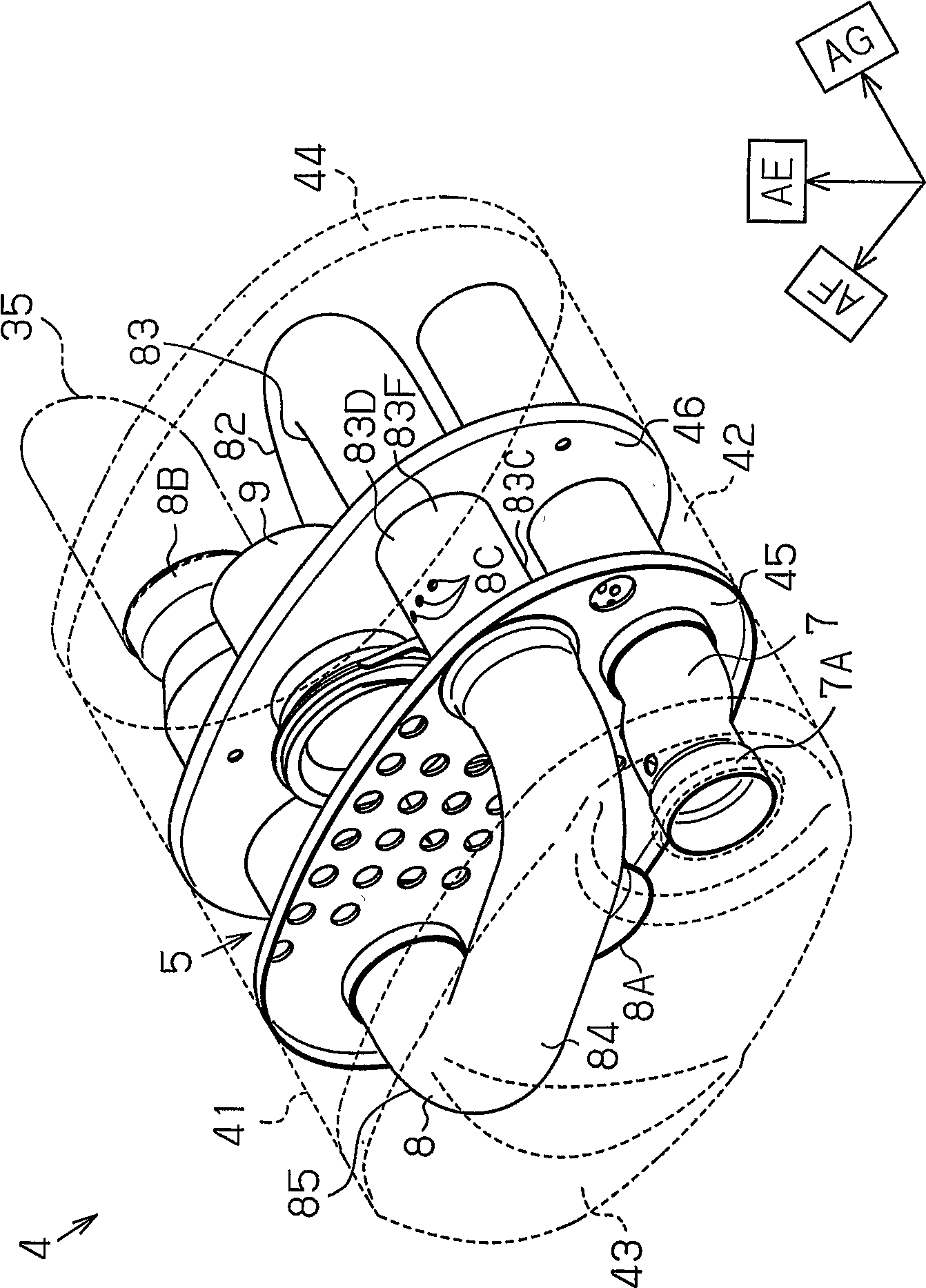

[0067] Figure 1 to Figure 2 9 shows the first embodiment of the present invention.

[0068] figure 1 The exhaust system of the vehicle 1 according to the first embodiment is shown. When defining a given position of the exhaust system as a reference, the side from the reference toward the engine 11 is referred to as the upstream side, and the side from the reference toward the exhaust outlet is referred to as the downstream side. The direction from the upstream side to the downstream side is called exhaust forward AA, and the direction from the downstream side to the upstream side is called exhaust reverse AB. The forward direction AA indicates the direction from the front side of the vehicle 1 to the rear side, and the reverse direction AB indicates the direction from the rear side of the vehicle 1 to the front side. Assume that the height direction AC of the vehicle coincides with the height direction, and that the width direction AD of the vehicle 1 coincides with the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com