Fuel injector with direct needle control and servo valve assistance

一种燃料喷射、喷射器的技术,应用在燃料喷射装置、特殊燃料喷射装置、装料系统等方向,能够解决燃料喷射器结构尺寸大等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

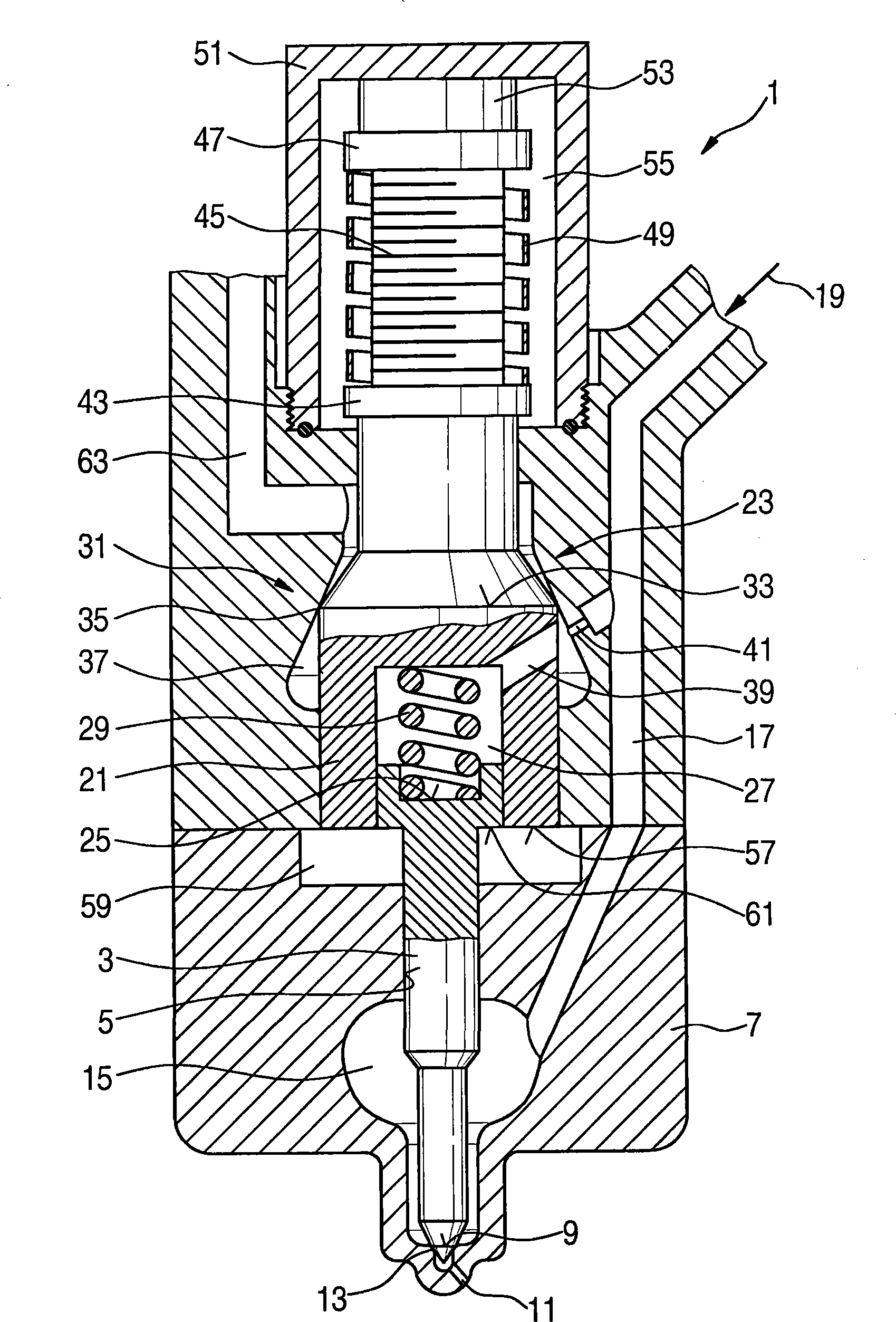

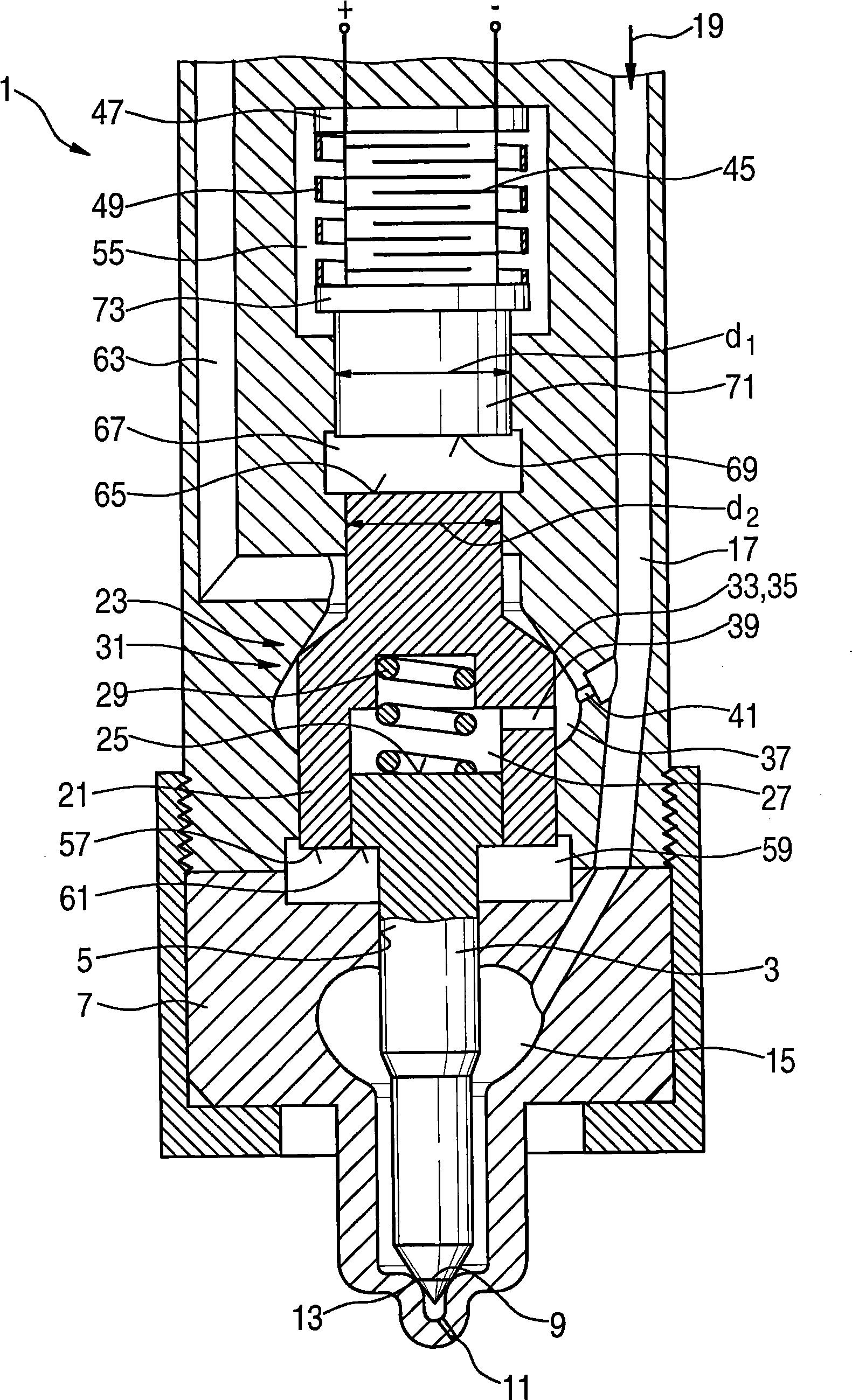

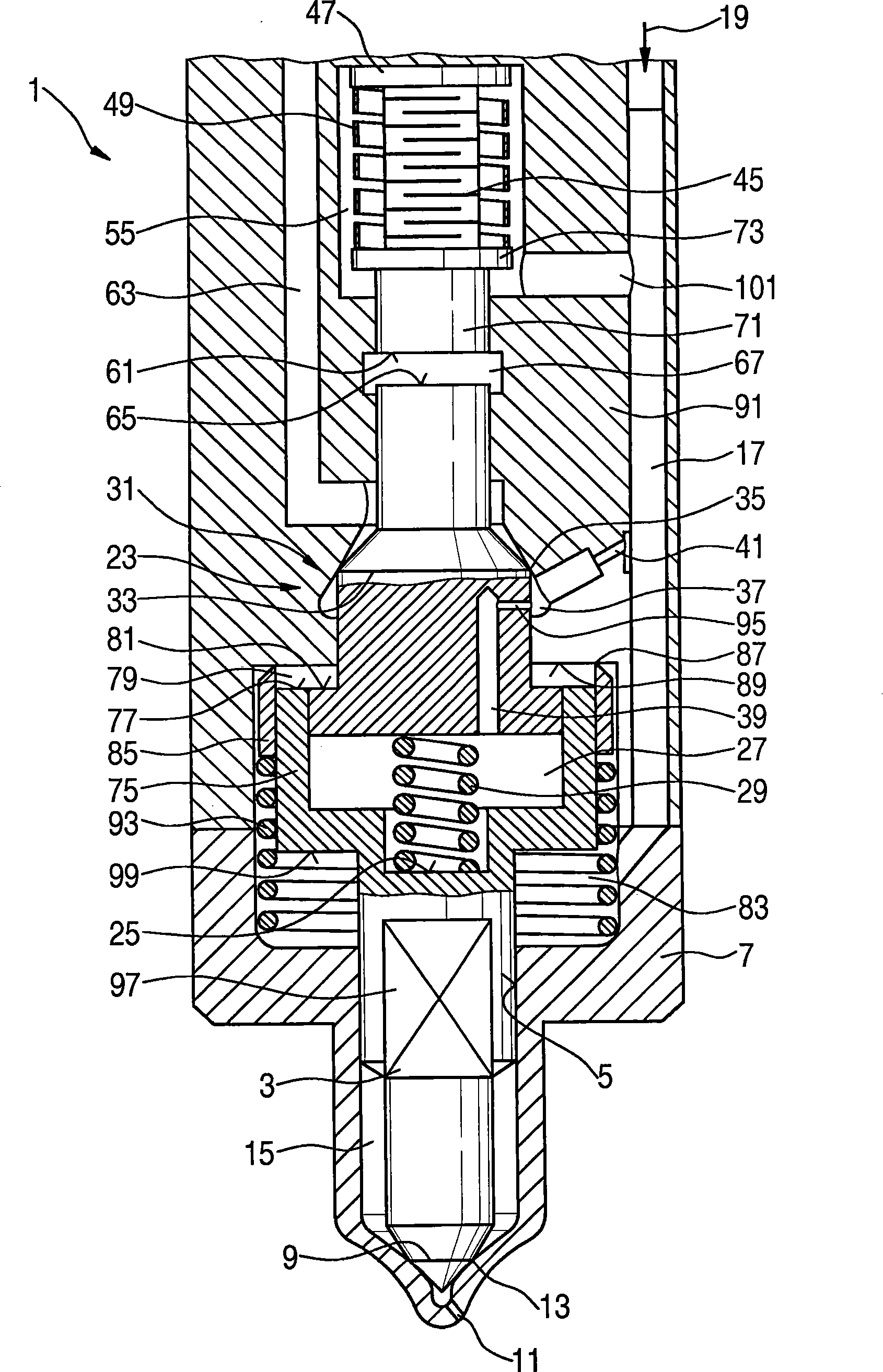

[0023] The fuel injector 1 includes an injection valve element 3 which is guided in a guide 5 in a lower housing part 7 . A sealing edge 9 is formed on the injection valve element 3 and rests in a seat 13 when the injection opening 11 is closed. In addition to the exemplary embodiment shown here in which fuel injector 1 has one injection opening 11 , more than one injection opening 11 can also be provided.

[0024] The injection valve element 3 is surrounded by a nozzle chamber 15 . The nozzle chamber 15 is connected to a fuel inlet 19 via an inlet channel 17 . The fuel inlet 19 is in turn connected to a common rail system high-pressure accumulator (not shown here).

[0025] On its end facing away from the injection opening 11 , the injection valve element 3 has a piston section which is guided in an annular section 21 of the control piston 23 . An end face 57 is formed on the annular section 21 , which acts as a pressure face on the control chamber 59 . A shoulder 61 is f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com