Defluorination absorbing material based on aluminum base composite oxides and its preparation method and use and special device of the preparation method

A technology of aluminum-based composite and adsorption materials, which is applied in the direction of chemical instruments and methods, and other chemical processes, and can solve problems such as limitations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

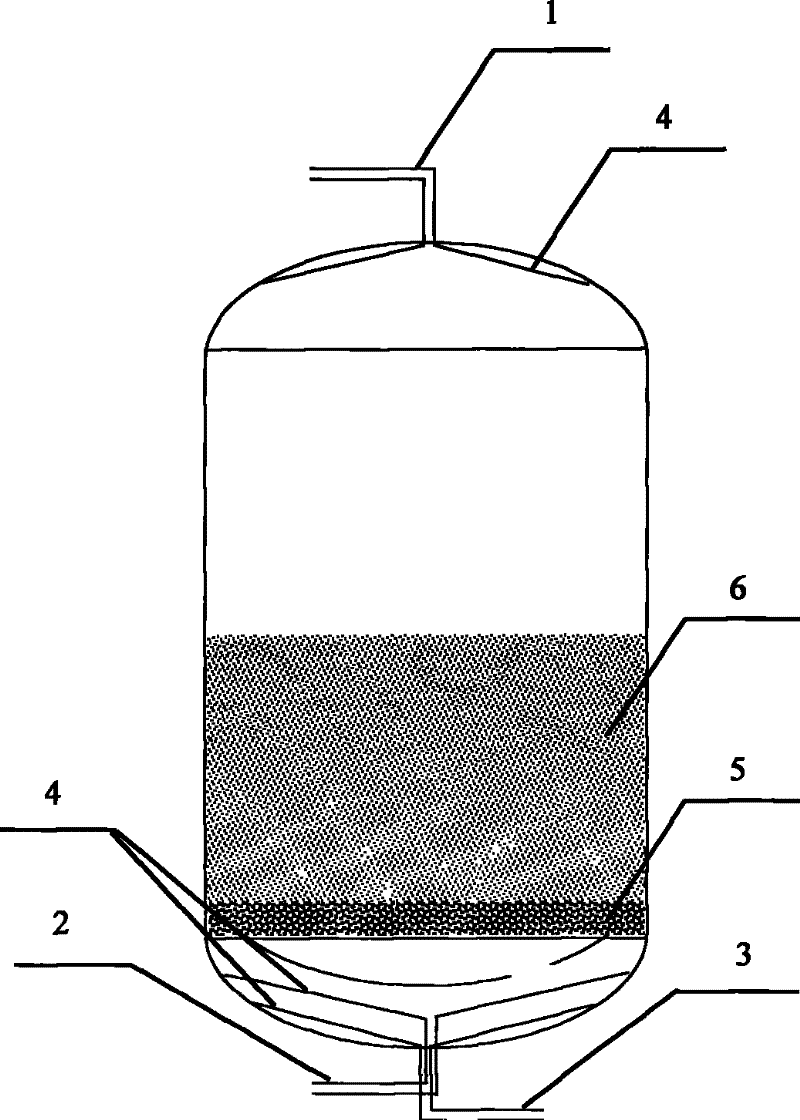

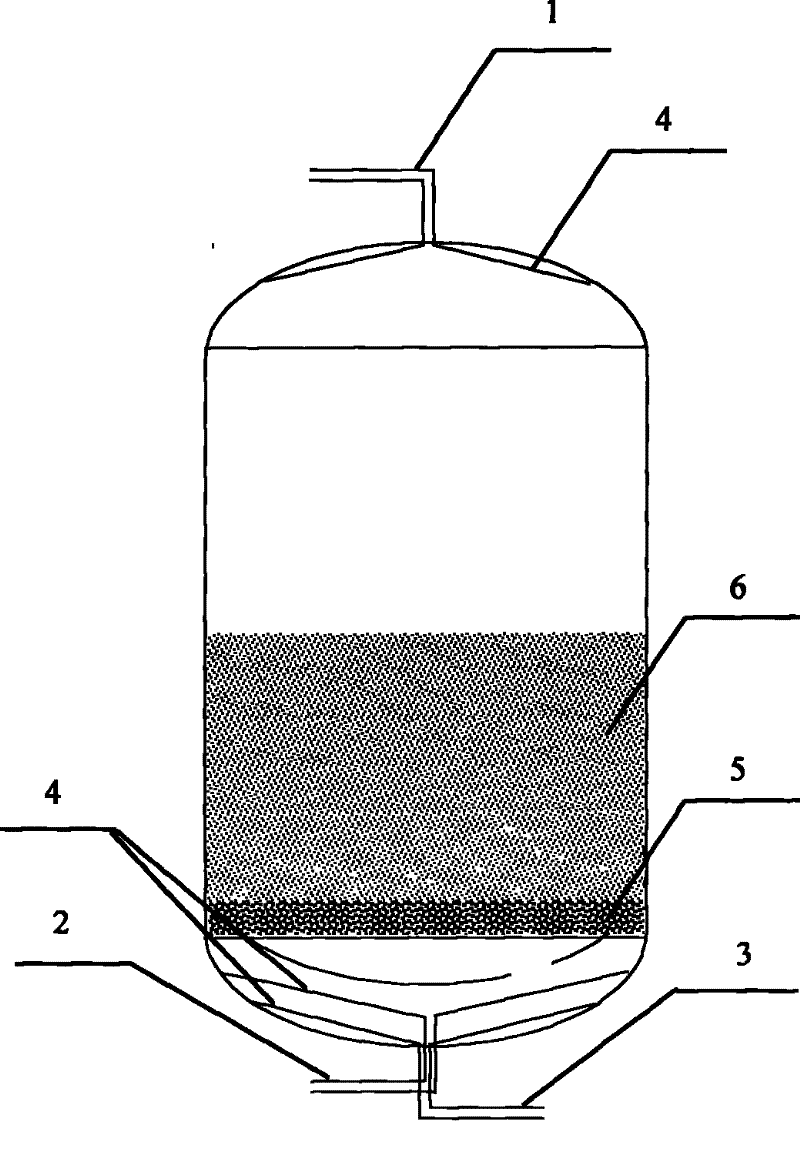

[0062] See figure 1 . The columnar water purification reactor based on the aluminum-based composite oxide fluorine removal material prepared by the in-situ preparation method has a water inlet 1 on the top, and a water distributor 4 at the water inlet in the columnar water purification reactor. There is a support layer 5 in the lower part of the device, a porous load matrix material 6 is arranged on the support layer, and a water distributor 4 is arranged under the support layer; a water outlet is opened at the bottom of the columnar water purification reactor below the water distributor 2 and the inlet 6 of aluminum salt solution and inorganic alkali solution. The diameter of the reactor is 1 m, the effective height is 1.8 m, and the filling height of the porous supporting matrix material 6 is 1.5 m.

[0063] Material preparation: use diatomite with a particle size range of 0.2mm to 0.4mm as the porous loading matrix, and fill it into a columnar water purification reactor; ...

Embodiment 2

[0067] The water purification reactor is the same as in Example 1.

[0068]Material preparation: Anthracite with a particle size range of 0.5 mm to 1.0 mm is used as a porous loading matrix, which is filled into a columnar water purification reactor; 20 g / L polyaluminum chloride (PAC) solution and 8 g / L NaOH are prepared respectively solution; use a pump to pump the NaOH solution into the above-mentioned water purification reactor until the anthracite is immersed and stop pumping the NaOH solution. After 30 minutes of immersion, the NaOH solution will be released through the water outlet; then pump the PAC solution into the above water purification reaction Stop pumping the PAC solution until the anthracite is submerged, let the PAC solution flow out through the water outlet after immersion for 10 minutes; let the PAC solution stand for 20 minutes intermittently, repeat the above method twice, and let the PAC solution stand for 20 minutes between each time. The aluminum-based ...

Embodiment 3

[0072] The water purification reactor is the same as in Example 1.

[0073] Material preparation: use quartz sand with a particle size range of 0.8 mm to 2.0 mm as the porous loading matrix, and fill it into a columnar water purification reactor; prepare Al 2 (SO 4 ) 3 with FeCl 3 mixed solution (wherein Al 2 (SO 4 ) 3 The concentration is 20g / L, FeCl 3 The concentration is 5g / L) and 10g / L NaOH solution; pump the NaOH solution into the above-mentioned water purification reactor until the quartz sand is submerged and stop pumping the NaOH solution, and after immersion for 30 minutes, pass the NaOH solution through the water outlet released; then Al 2 (SO 4 ) 3 with FeCl 3 pump the mixed solution into the above-mentioned water purification reactor until the quartz sand is submerged and stop pumping into the Al 2 (SO 4 ) 3 with FeCl 3 The mixed solution, soaked for 10 minutes to make Al 2 (SO 4 ) 3 with FeCl 3 The mixed solution flows out through the water outle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com