Radiating structure and use method thereof

A technology of heat dissipation structure and heat dissipation parts, applied in the direction of cooling/ventilation/heating transformation, electrical components, electric solid devices, etc., can solve the problems of difficult disassembly and assembly, long working hours, etc., and achieve the effect of easy fixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

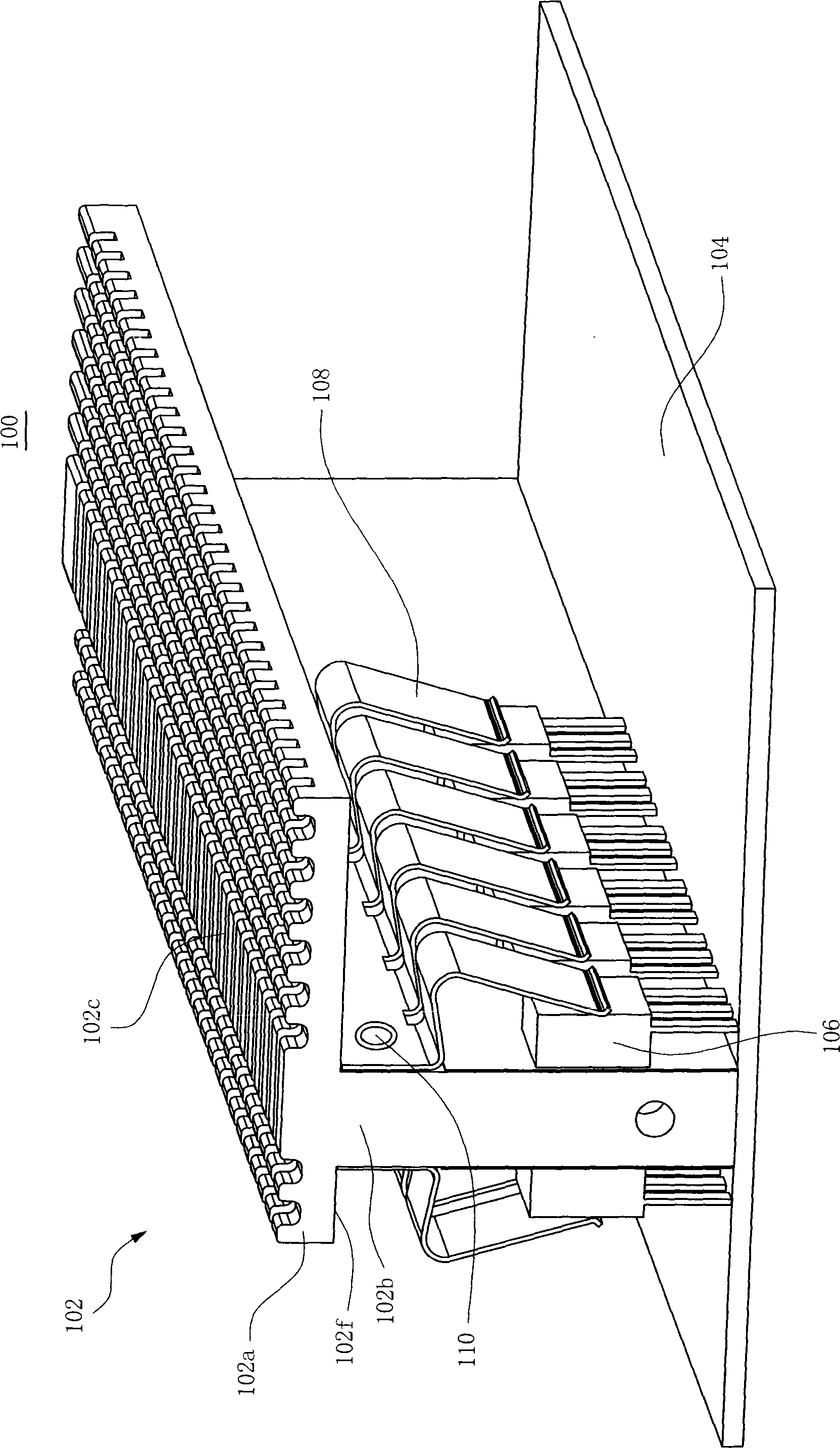

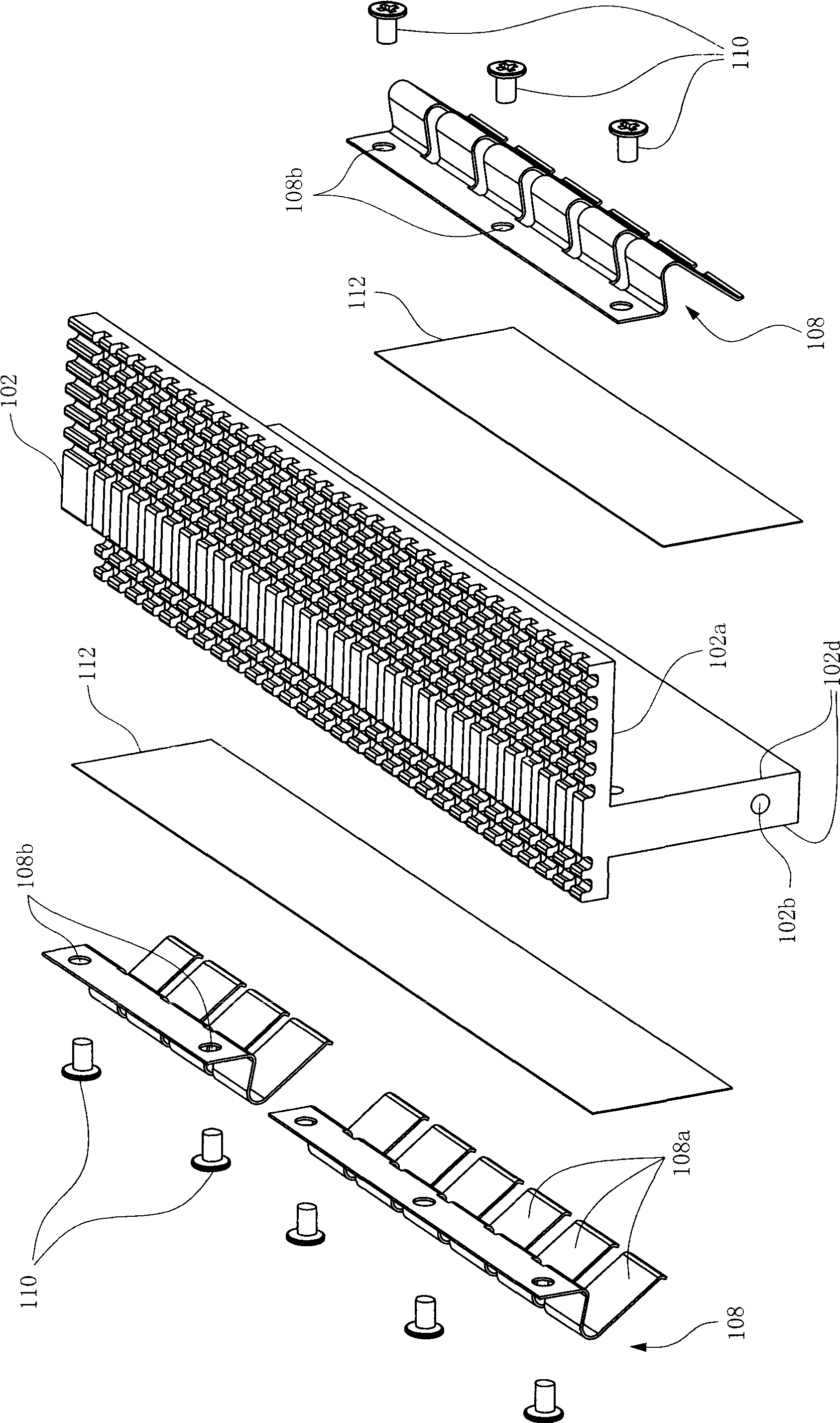

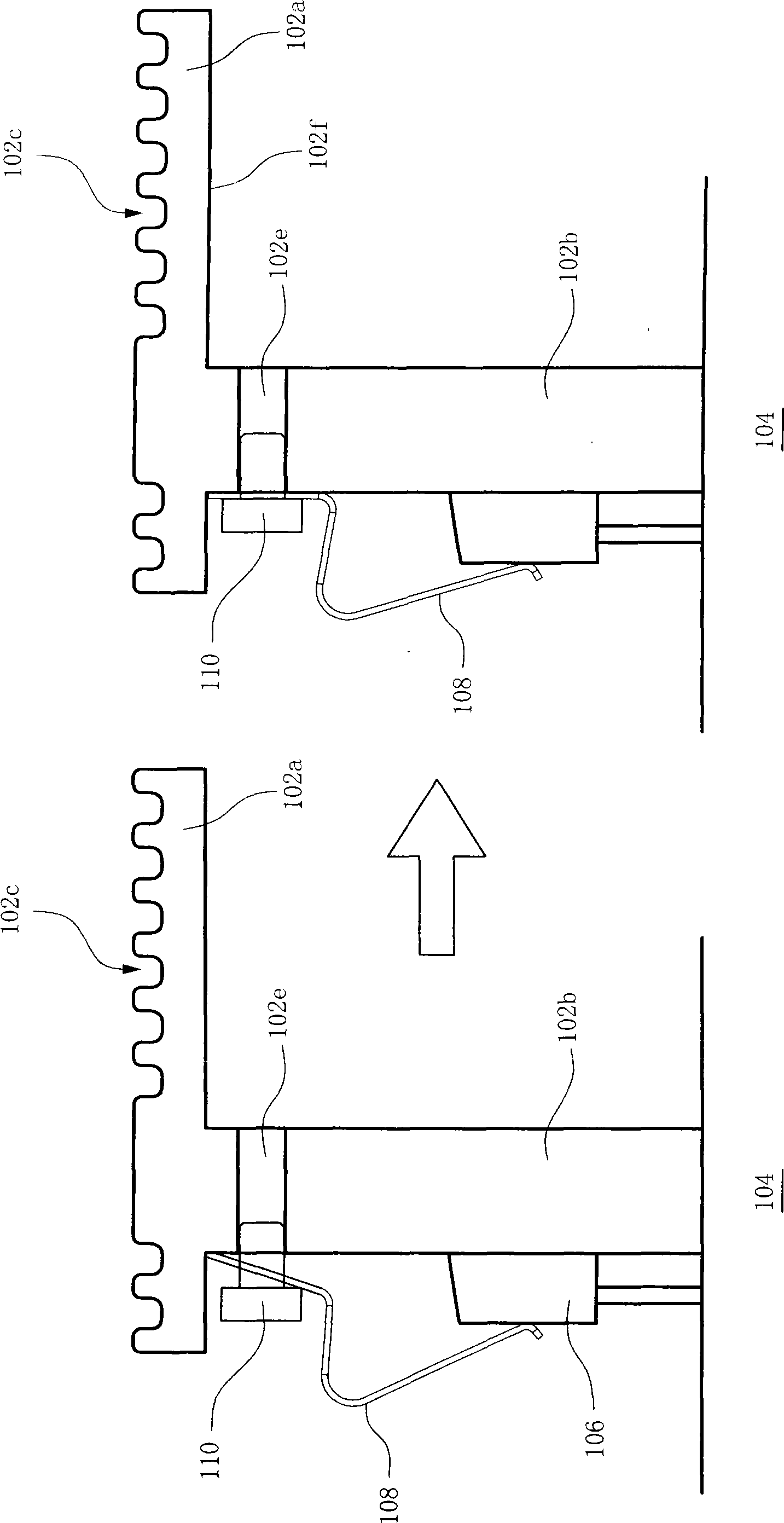

[0013] Please refer to figure 1 , shows a state in which a heat dissipation structure is mounted on a circuit board according to a preferred embodiment of the present invention. The circuit board 104 has two rows of right-angle transistors 106 (right-angle heating elements) upright connected to the circuit board. In order to increase the heat dissipation efficiency of the right-angle transistor 106 , a heat dissipation structure 100 is installed so that the heat generated by the right-angle transistor 106 can be conducted to the air more quickly. The heat dissipation structure 100 mainly includes a heat dissipation element 102 and a clamping portion 108 . The clamping portion 108 is locked on the support plate 102b by screws 110 . The heat sink 102 has a top plate 102a and a support plate 102b. The top surface of the top plate 102a is a heat dissipation surface 102c. The heat dissipation surface 102c is covered with protruding heat dissipation structures to increase the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com