Thermal transfer printer with ribbon saving function

A thermal transfer printer, functional technology, applied in printing and other directions, can solve problems such as waste and wasted carbon ribbon, and achieve the effect of reducing waste and printing accurately

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

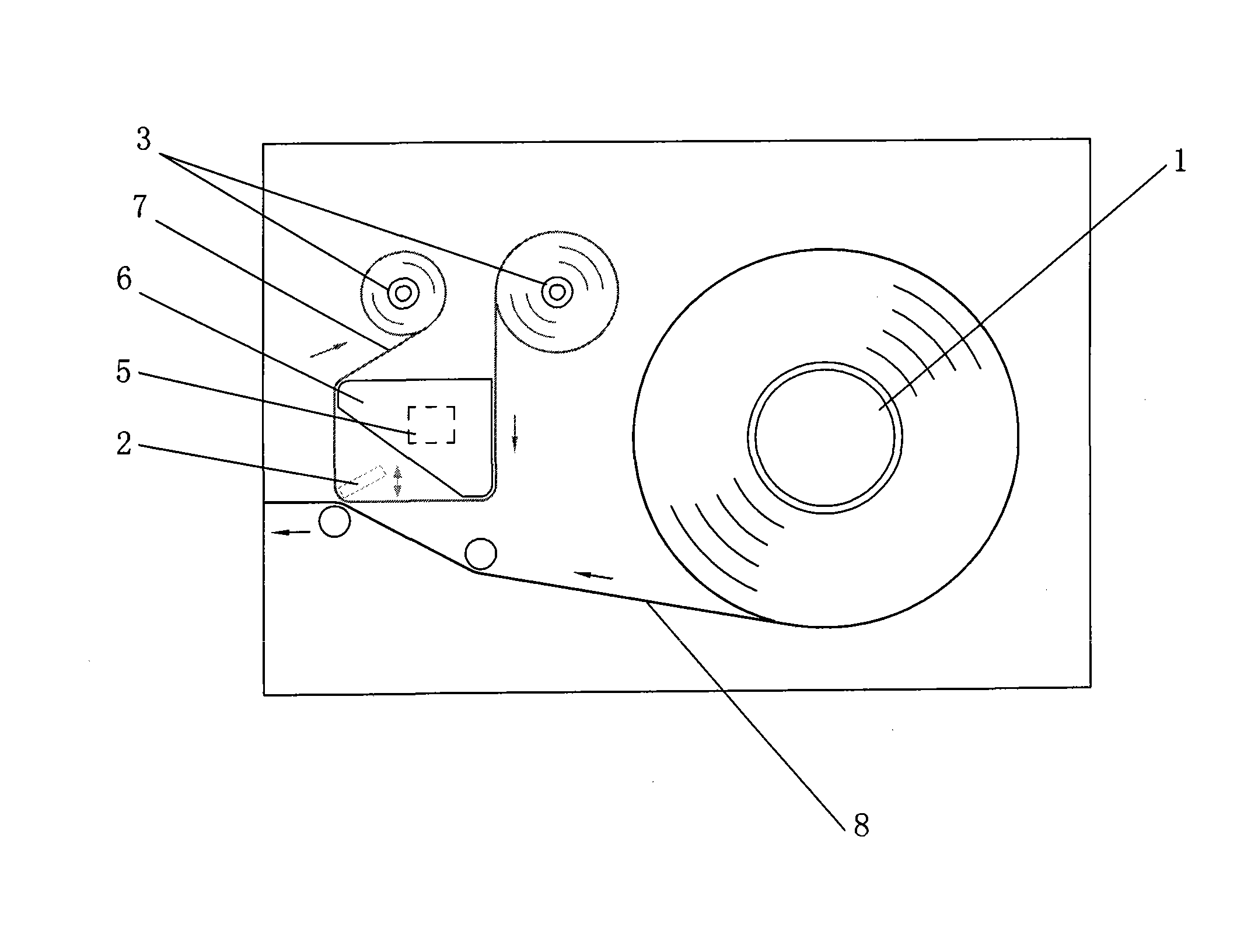

[0024] refer to Figure 1 to Figure 2 , the present invention is implemented like this:

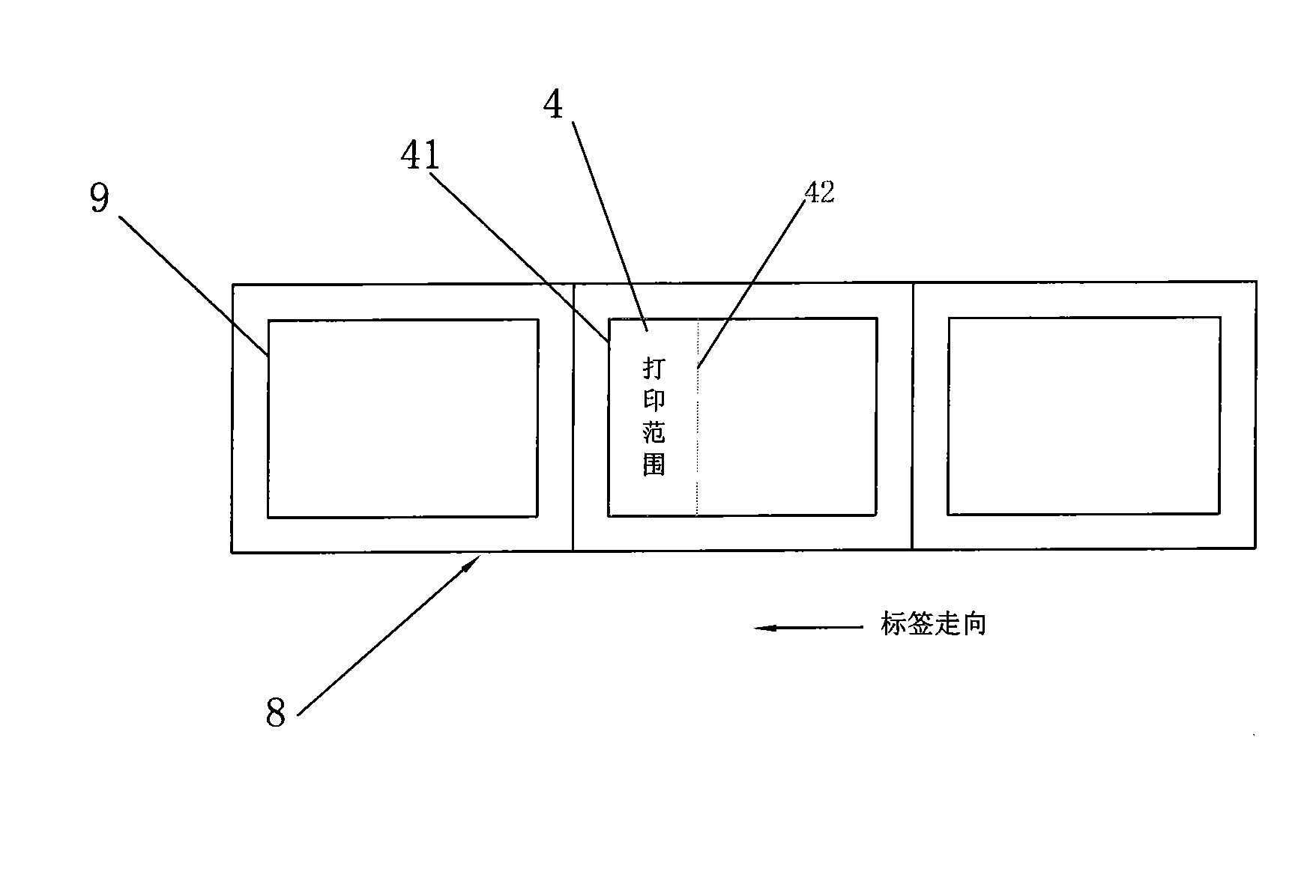

[0025] exist figure 1 Among them, a thermal transfer printer with the function of saving carbon ribbons includes a printer paper feeding device (1) and a print head (2), and it also includes a ribbon driving device (3) controlled separately from the printer paper feeding device (1) ), the print head (2) is controlled by the print head clamping device (6), the print head clamping device (1) includes a detection module (5) for detecting the printing position (4), and the detection module (5) detects At the printing position (4), the software controls the clamping device (6) of the print head to perform the clamping action, and the ribbon (7) is controlled by the ribbon transmission device (3) to move synchronously with the printing paper (8) and start printing. When the printing is completed, the software controls the print head clamping device (6) to loosen and separate from the printing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com