Multi-headed fast tearing butt coupler and fabricated part

A butt buckle and fast technology, applied in the field of prefabricated strong fasteners and prefabricated parts manufacturing, can solve problems such as unsatisfactory and no impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

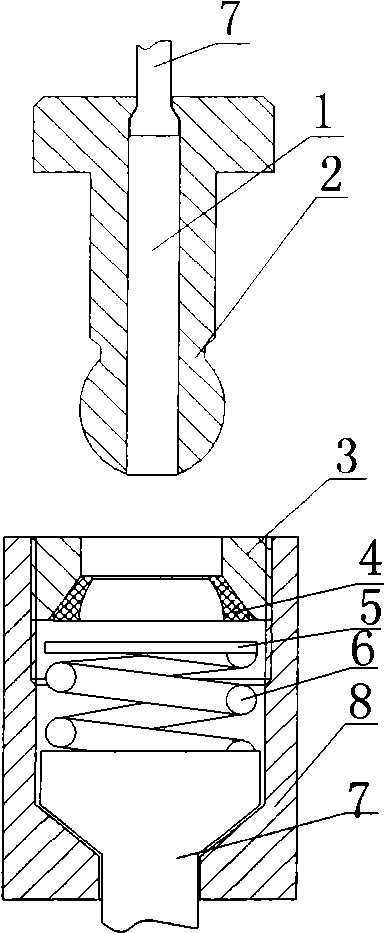

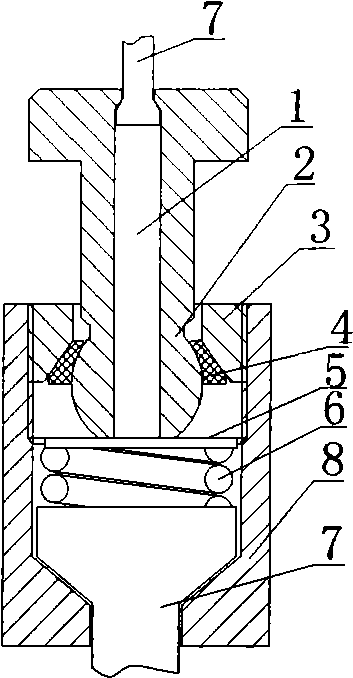

[0015] Embodiment 1: with reference to attached figure 1 and 2 . Multi-head fast strong pull butt joint fastener, which includes a plug 2, the top pull nut 8 is an internal thread structure, the internal thread is a strong wire buckle, a steel hole is opened in the center of the bottom of the cap, and the periphery of the steel hole is a steel bar heading card platform, the plug 2 is a hollow plug, the center of the hollow bottom of the plug 2 is provided with a steel bar hole 1, the periphery of the steel bar hole is a steel bar heading block, and the compression spring 6 is located in the top pull nut 8, One end of the compression spring 6 is located on the steel bar heading card table, and the other end is equipped with a tapered sleeve 4 composed of two or more pieces (generally two pieces form a tapered sleeve-the cavity of the sleeve is tapered and vertically vertical). through, see attached figure 1 and 2 ), the threaded sleeve 3 is screwed into the top pull nut 8 a...

Embodiment 2

[0016] Embodiment 2: On the basis of Embodiment 1, that is to say, the other end of the compression spring 6 is provided with a gasket 5, and the tapered sleeve 4 composed of two or more pieces is located on the gasket 5.

Embodiment 3

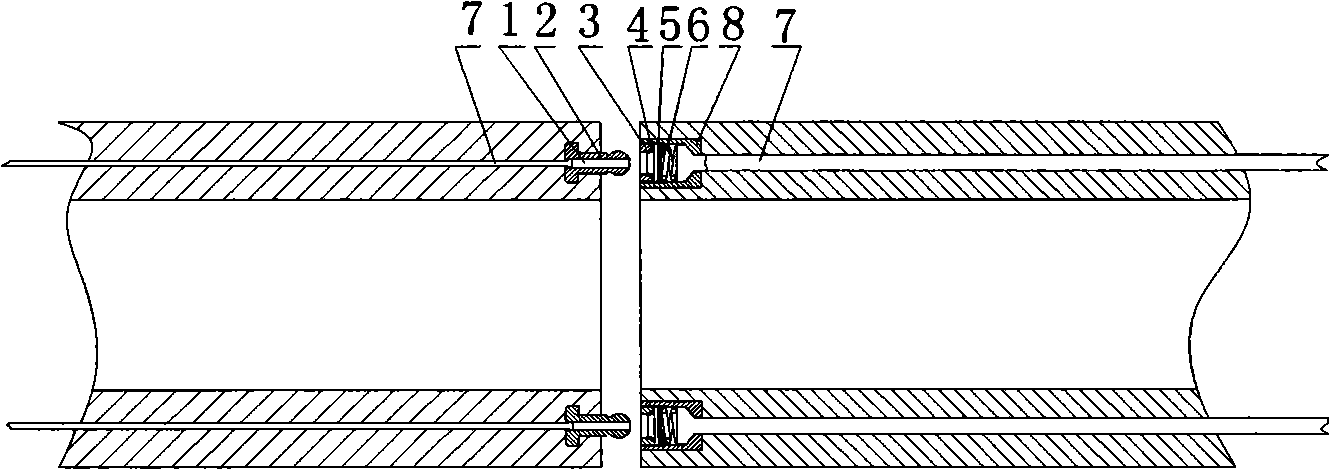

[0017] Embodiment 3: with reference to attached image 3 and 4 . On the basis of Example 1, the prefabricated part is composed of multi-head fast and strong butt joint fasteners. The top pull nut 8 is an internal thread structure, and the internal thread is a strong wire buckle. There is a steel bar hole in the center of the bottom of the cap. The periphery of the steel bar header card platform, the two ends of the prefabricated longitudinal steel bars 7 are upset and clamped on the header card platform, the connector 2 is a hollow connector, and the center of the hollow bottom of the connector is opened. There is a steel bar hole 1, and the periphery of the steel bar hole is a steel bar upsetting card platform. The two ends of the longitudinal steel bar of the prefabricated part are upsetting and clamped on the upsetting card platform. The compression spring 6 is located in the top pull nut 8. The compression spring One end of 6 is located on the head of the steel bar, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com