Simulation experimental system for controlling mine tunnel dust environment

A technology for controlling simulation and test systems, which is applied in aerodynamic tests, dust prevention, mining equipment, etc., and can solve problems such as the difficulty of simulating the on-site environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

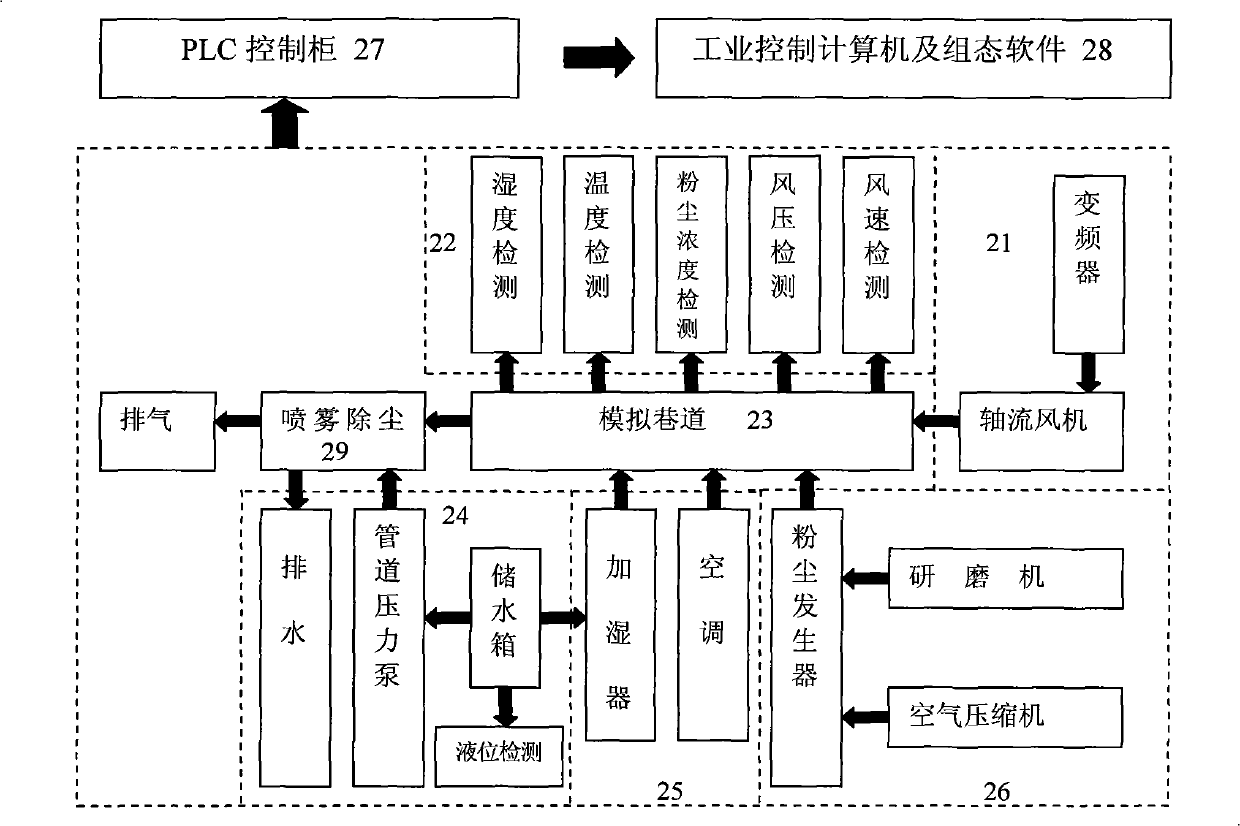

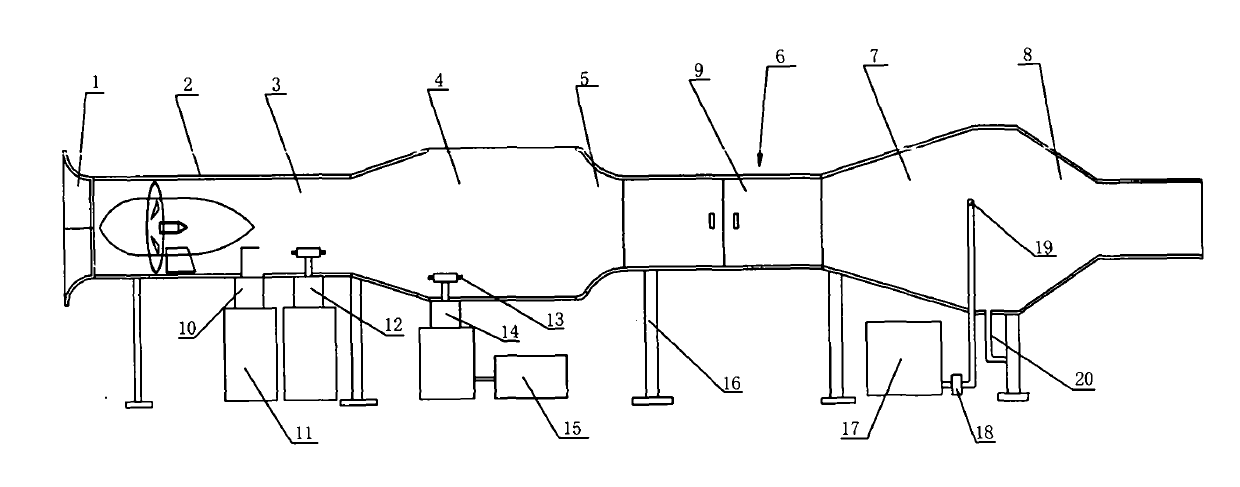

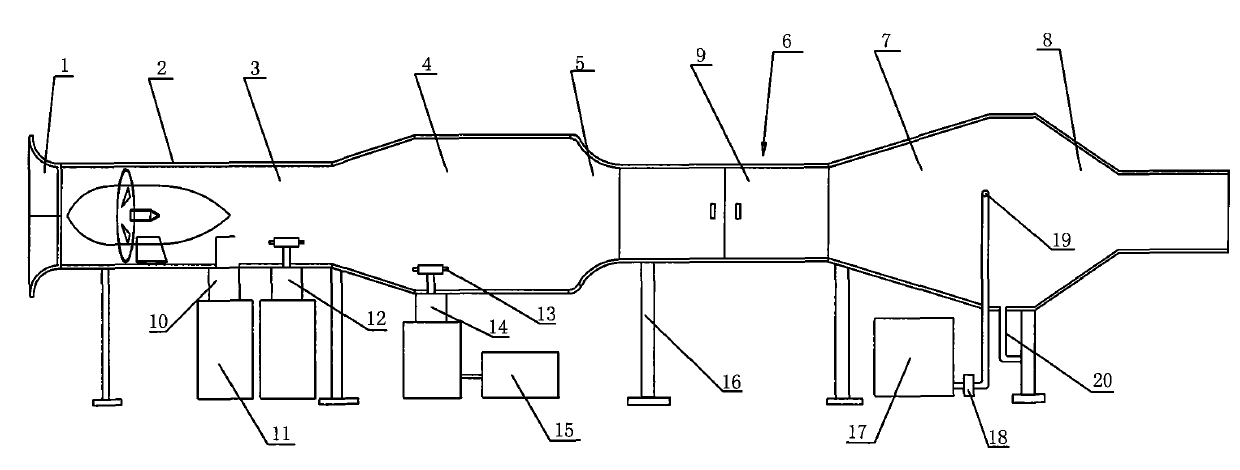

[0014] combine figure 1 and figure 2 , a mine roadway dust environment control simulation test system, including simulated roadway 23, ventilation system 21, dust generation system 26, temperature and humidity control system 25, water supply and drainage system and dust removal system 24, 29, signal detection system 22 and computer control and data analysis systems27,28. The main body wall of the simulated roadway 23 adopts a multi-layer structure, wherein the inner and outer layers are made of metal materials such as stainless steel, the middle layer is an insulation layer, and the insulation layer adopts high-aluminum needle-punched blankets. An observation window 9 is provided, and the observation window 9 is made of transparent double-layer insulating glass. In order to facilitate operation, a support frame 16 is used to support the main body of the simulated roadway, so that the entire simulated roadway is 1m above the ground. The ventilation system 21 includes an axia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com