Low-dimension material dynamic tensile loading measurement system

A dynamic stretching and measurement system technology, applied in the direction of measuring devices, applying stable tension/pressure to test material strength, instruments, etc., can solve the problems of inability to quantitatively describe mechanical parameters, low loading frequency, etc., and achieve compact structure and use convenient effect

Inactive Publication Date: 2010-12-01

TSINGHUA UNIV

View PDF3 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Zhang Guangping and others from the Institute of Metal Research, Chinese Academy of Sciences invented a performance test system and test method for thin film materials under the coupling of electricity / heat / force [200610047538.3]. This method uses alternating current to cause Joule heat in the metal wire. The difference in thermal expansion coefficient realizes thermal fatigue loading on metal wires. This method requires that the test object is also limited to metal materials. The loading method produces thermal deformation through thermal adaptation, and the loading frequency is not high.

The methods mentioned above are mainly for the testing of metal thin film materials, and the dynamic loading of the material is achieved through indirect methods. The loading frequency is not high, and the mechanical parameters of the material under dynamic loading cannot be quantitatively described.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment approach

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

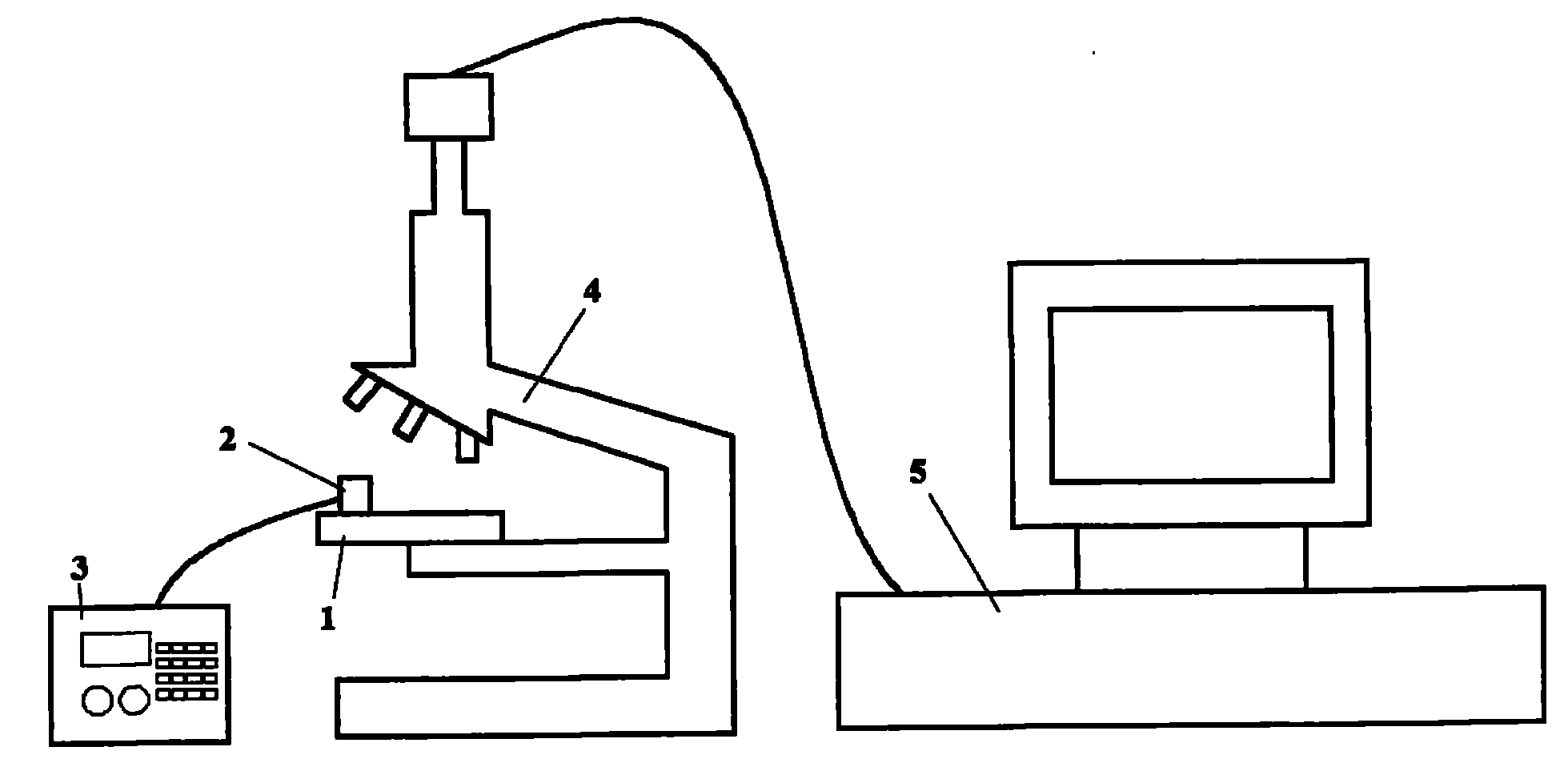

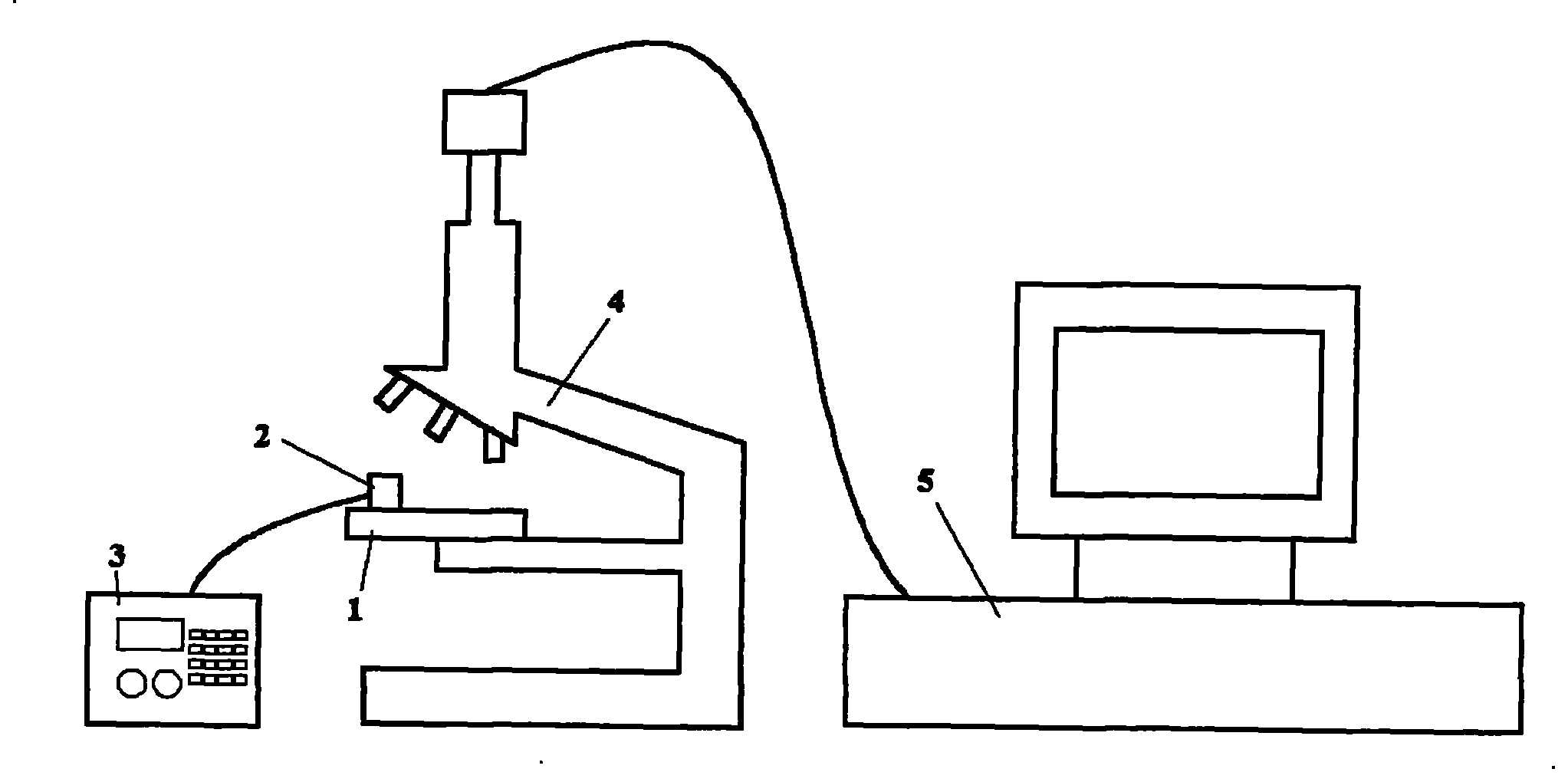

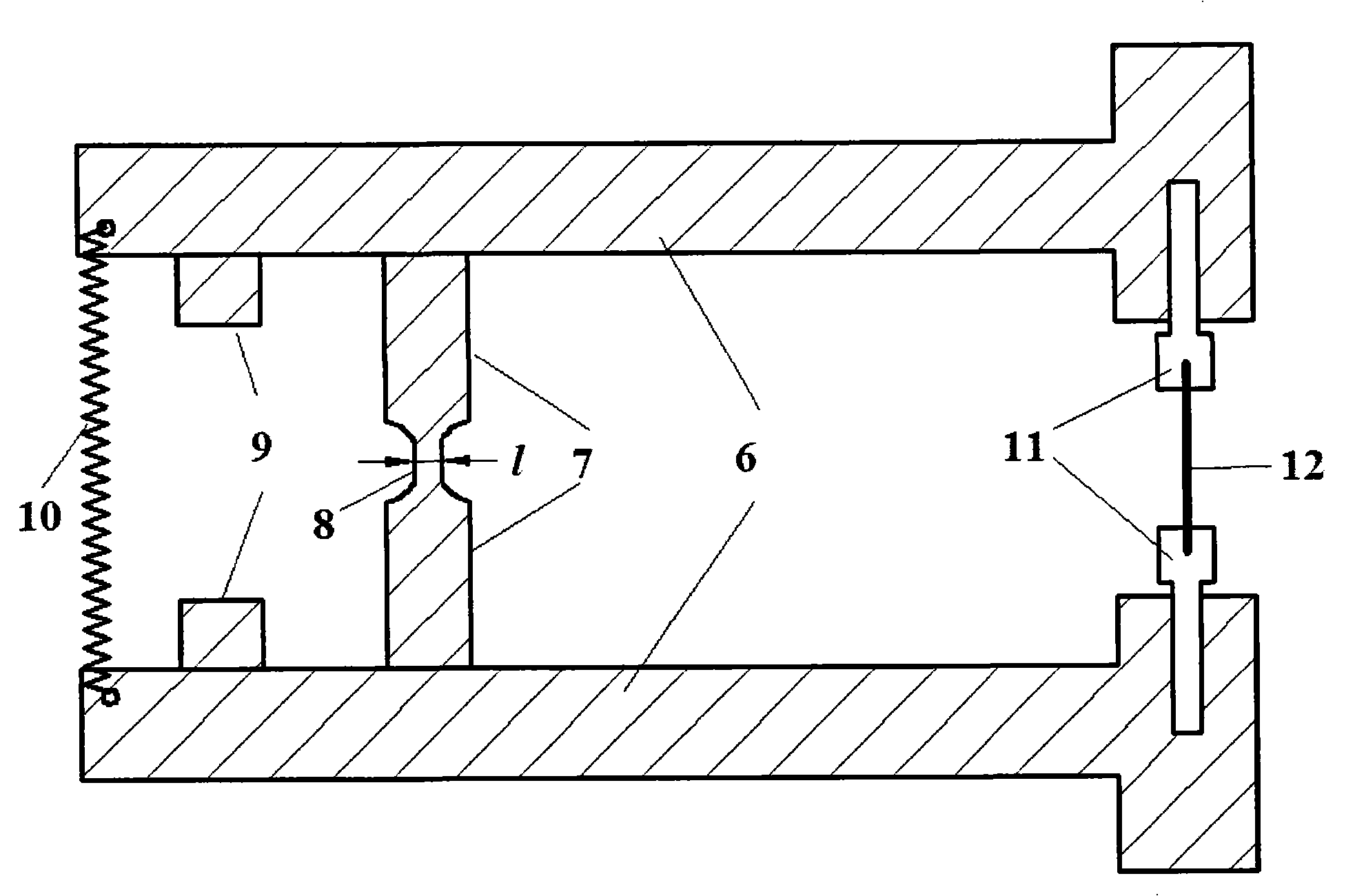

The invention relates to a low-dimension material dynamic tensile loading measurement system which belongs to the technical field of the optical measurement mechanics, the engineering material, and thThe invention relates to a low-dimension material dynamic tensile loading measurement system which belongs to the technical field of the optical measurement mechanics, the engineering material, and thce under the condition of dynamic loading; and the low-dimension material dynamic tensile loading measurement system has convenient use and compact structure.ece under the condition of dynamic loading; and the low-dimension material dynamic tensile loading measurement system has convenient use and compact structure.e mechanical property testing, comprises an optical measurement system, a dynamic loading device and piezoelectric ceramics and a control system thereof and can realize the dynamic performance test ofe mechanical property testing, comprises an optical measurement system, a dynamic loading device and piezoelectric ceramics and a control system thereof and can realize the dynamic performance test ofvarious low-dimension materials under the high frequency loading condition. The low-dimension material dynamic tensile loading measurement system adopts the piezoelectric ceramics drive to realize th various low-dimension materials under the high frequency loading condition. The low-dimension material dynamic tensile loading measurement system adopts the piezoelectric ceramics drive to realize the high frequency loading with the highest frequency reaching up to several kilohertz, amplifies the micro displacement of the piezoelectric ceramics through an precision-machined displacement amplifice high frequency loading with the highest frequency reaching up to several kilohertz, amplifies the micro displacement of the piezoelectric ceramics through an precision-machined displacement amplification lever to be fit for the tests of various hardness materials, adopts a high definition digital image relevant measurement system to measure the deformation situation of the surface of a tested piation lever to be fit for the tests of various hardness materials, adopts a high definition digital image relevant measurement system to measure the deformation situation of the surface of a tested pie

Description

Low-dimensional material dynamic tensile loading measurement system Technical field A low-dimensional material dynamic tensile loading measurement system belongs to the technical field of optical measurement mechanics, engineering materials, and mechanical performance testing. Background technique With the development of micro-nano science and technology, the application of micro-electromechanical systems (MEMS) has become more and more extensive, and various low-dimensional materials such as silicon films and metal films are widely used in the production of microelectronic mechanical systems. The properties of these materials directly affect the reliability of the microelectronic mechanical system, so accurate and reliable testing of the mechanical properties of such materials is very important. At this stage, there has been relatively good research on the static tensile mechanical properties of these low-dimensional materials, and a variety of tensile loading systems have be...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): G01N3/08G01B11/16

Inventor 谢惠民花韬张建民

Owner TSINGHUA UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com