Bearing experiment table capable of applying complex load

A complex load and test bench technology, applied in the direction of mechanical bearing testing, etc., can solve problems such as lack of general applicability, inability to apply dynamic and eccentric loads, and no power device.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

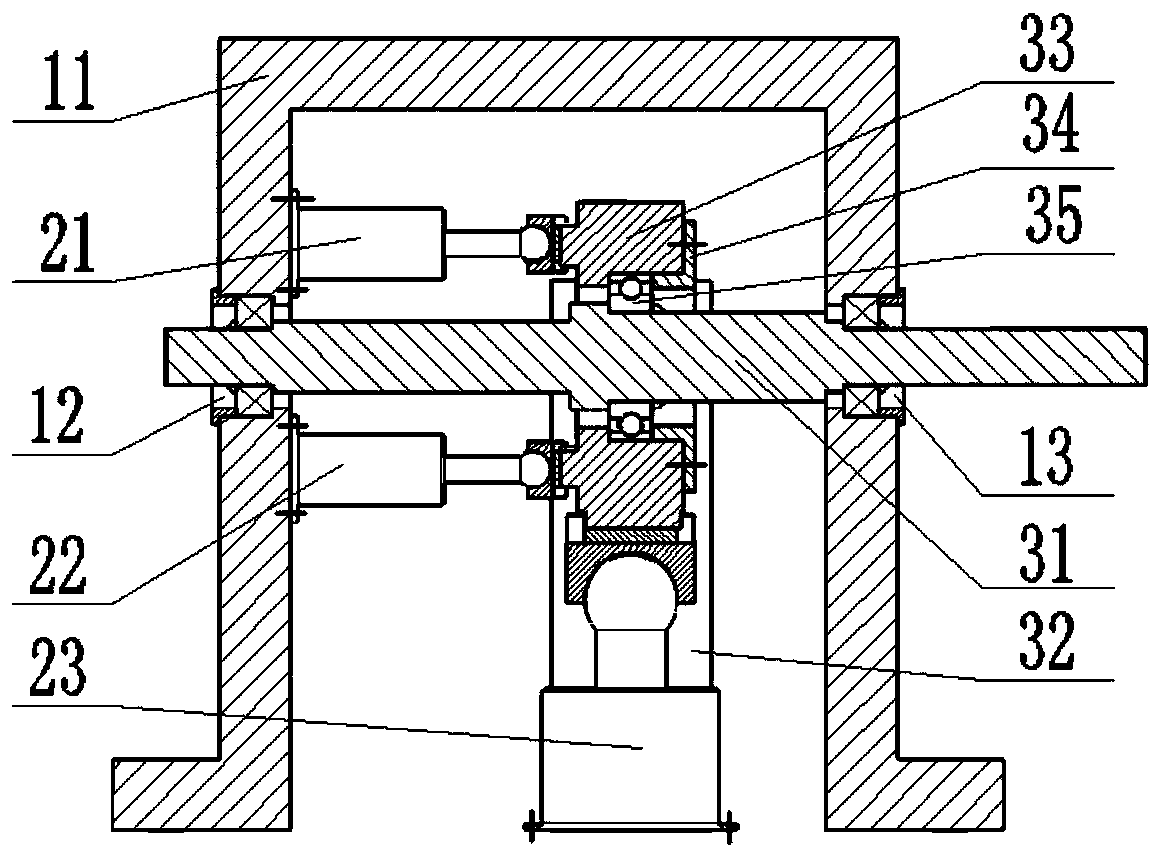

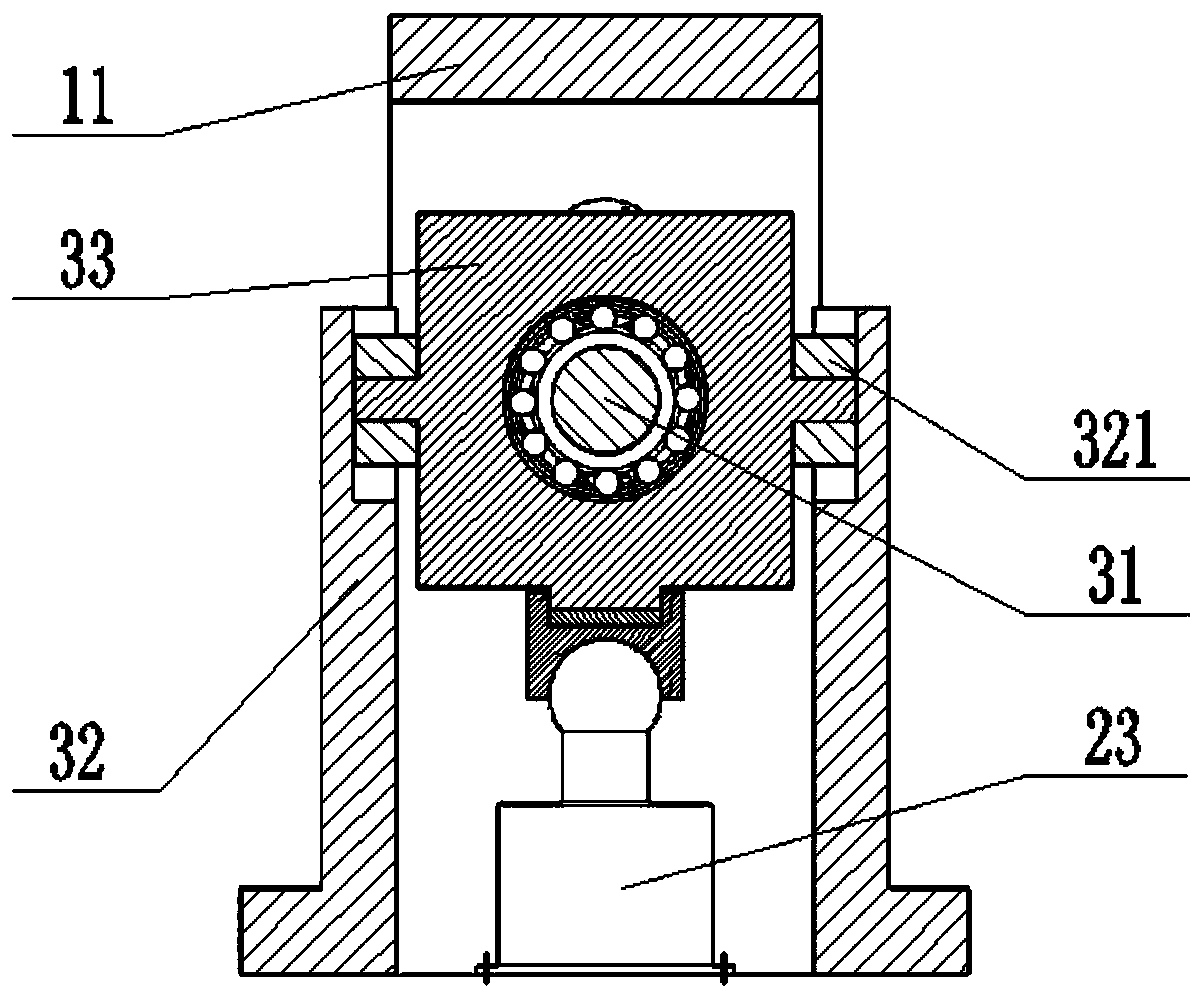

[0031] The specific implementation manners of the present invention will be further described below in conjunction with the accompanying drawings and technical solutions.

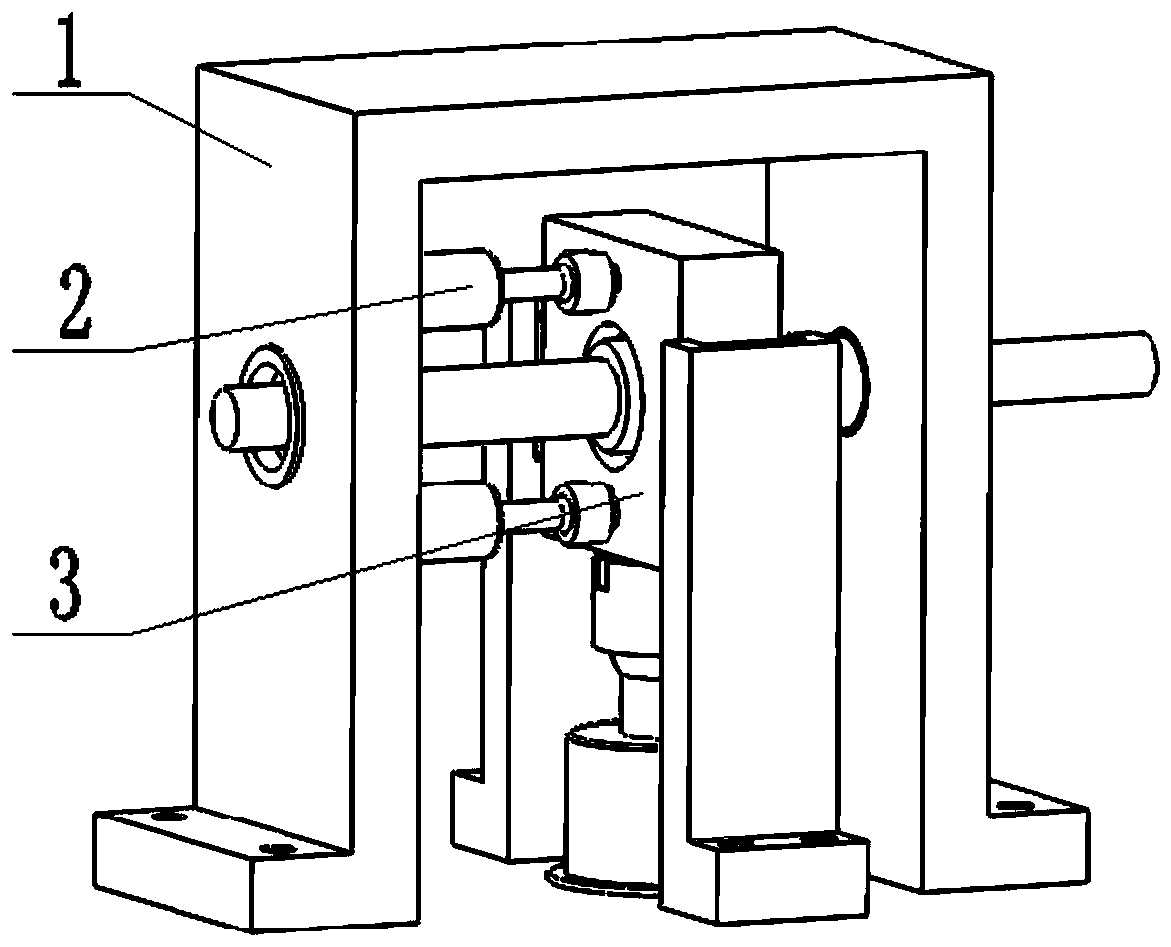

[0032] Such as figure 1 with Figure 8 As shown, a bearing test bench capable of applying complex loads according to the present invention includes a supporting device 1 , a loading device 2 , an experimental device 3 and a testing device 4 . The supporting device 1 is the supporting device of the loading device 2 and the testing device 3; the loading device 2 is the core device of the bearing test bench, and the loading device 2 can complete the application of complex loads; the experimental device 3 is the installation device of the experimental bearing; the testing device 4 The test device can be arranged according to the needs of the experimenter, and it is generally arranged around the experimental device 3.

[0033] Such as figure 2 As shown, the support device 1 includes an overall support 11 of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com