High-parameter turbine mechanical airflow excitation test measuring device and method

A technology of turbomachinery and measuring device, which is applied in the direction of measuring device, vibration test, and testing of machine/structural components, etc., can solve problems such as inability to measure, difficult to assess the problem of air flow excitation of turbomachinery, and achieves strong applicability and easy installation. and the effect of disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

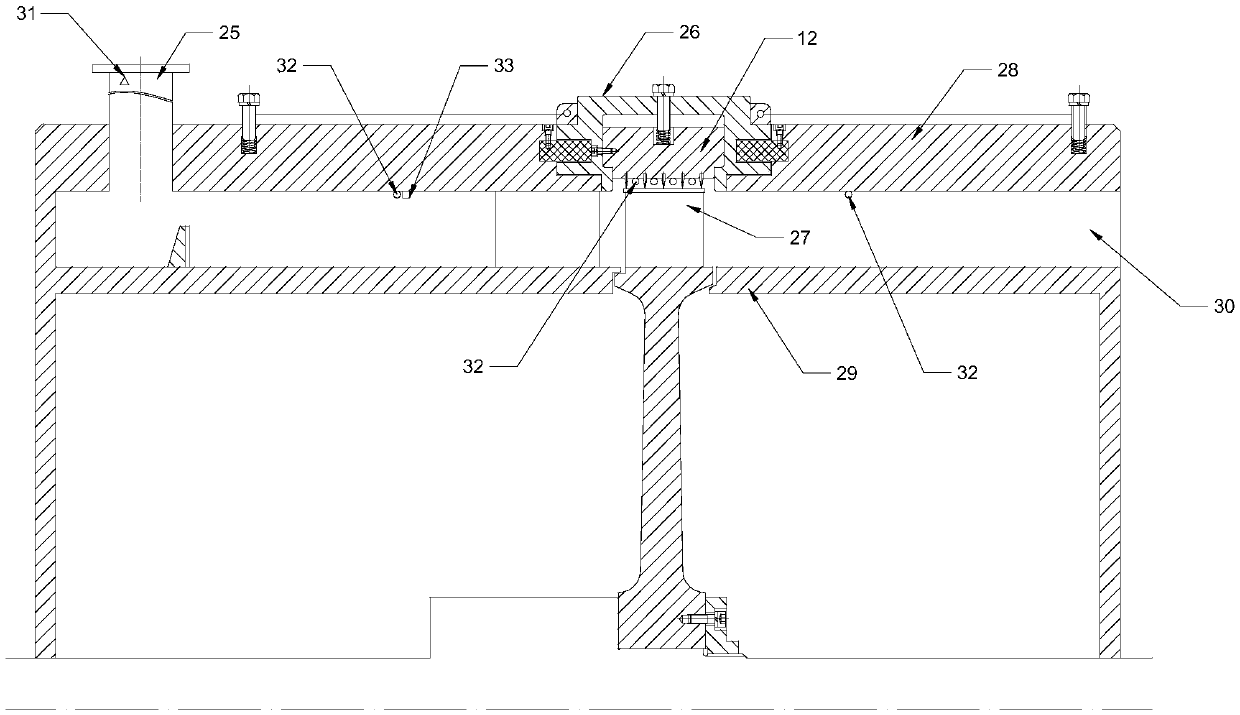

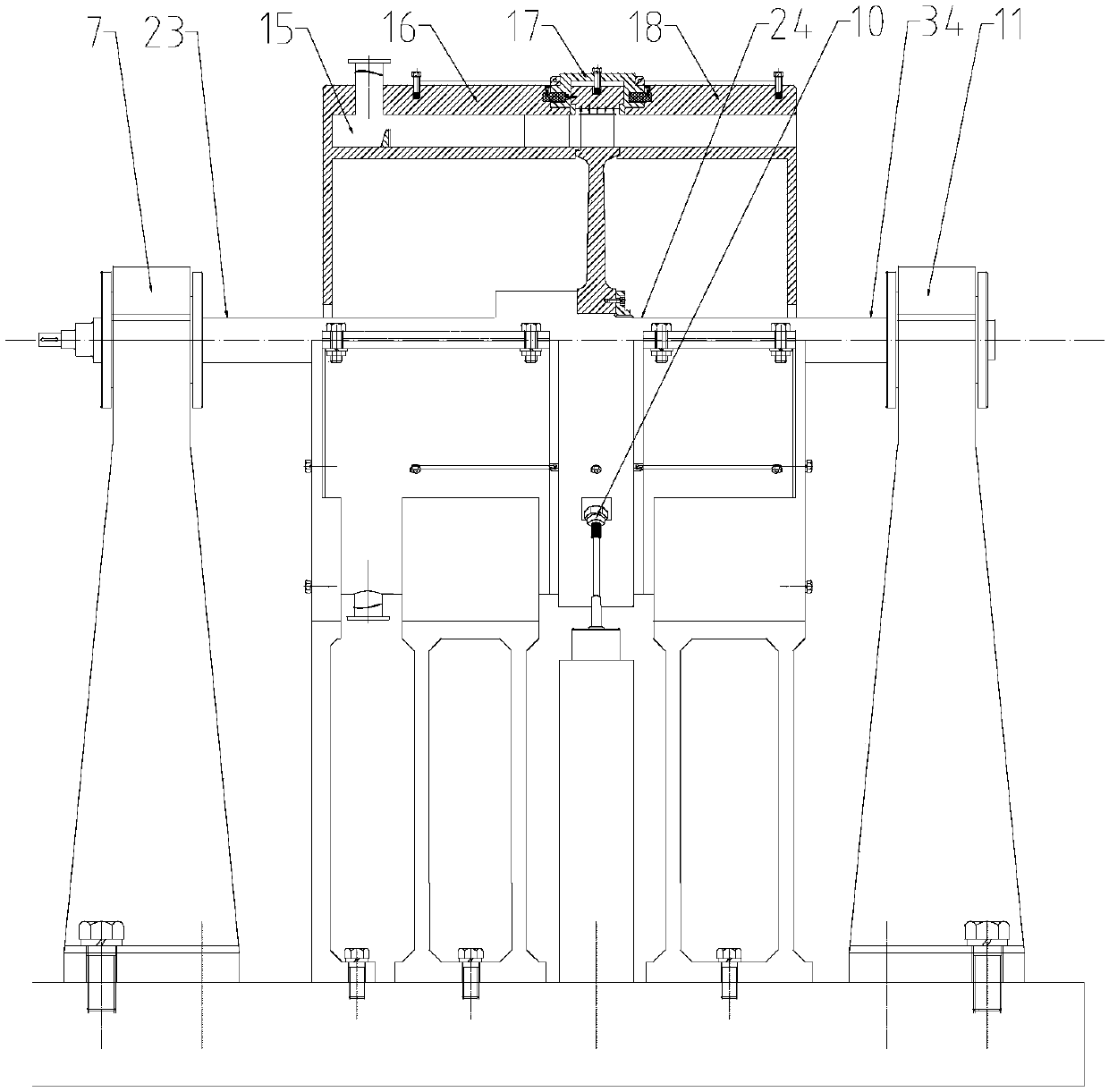

[0030] The present invention will be described in further detail below in conjunction with the accompanying drawings.

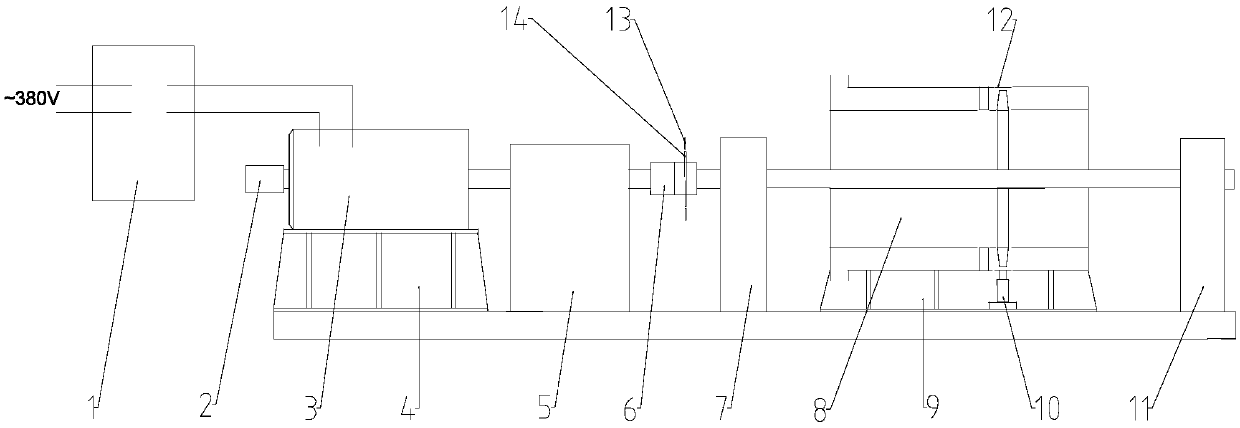

[0031] see figure 1 The present invention provides a high-parameter turbomachinery airflow excitation test and measurement device, including a rotor power system, a single-stage turbine test system and a signal measurement system.

[0032] The rotor power system includes an electrical control cabinet 1, a speed measuring motor 2, a DC motor base 4, a gear box 5, and a three-phase asynchronous motor 3 installed on the DC motor base 4. The output terminal of the three-phase asynchronous motor 3 is connected to the gear transmission The input end of the box 5 is connected, the output end of the gear box 5 is connected with the input end of the rotor 34 through the elastic coupling 6, the two ends of the rotor 34 are movably connected through the left bearing seat 7 and the right bearing seat 11, and the electrical control cabinet 1 is used It is used to provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com