Method for measuring and regulating clamping force of coke oven tamping tool hammer rod and measuring system

A clamping force, tamping machine technology, applied in the direction of measuring torque/torsion force during tightening, coke oven, mechanical treatment of coal loaded into the furnace, etc., to improve coke quality, good forming, and small tamping work Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The specific embodiments of the present invention will be described in detail below with reference to the drawings.

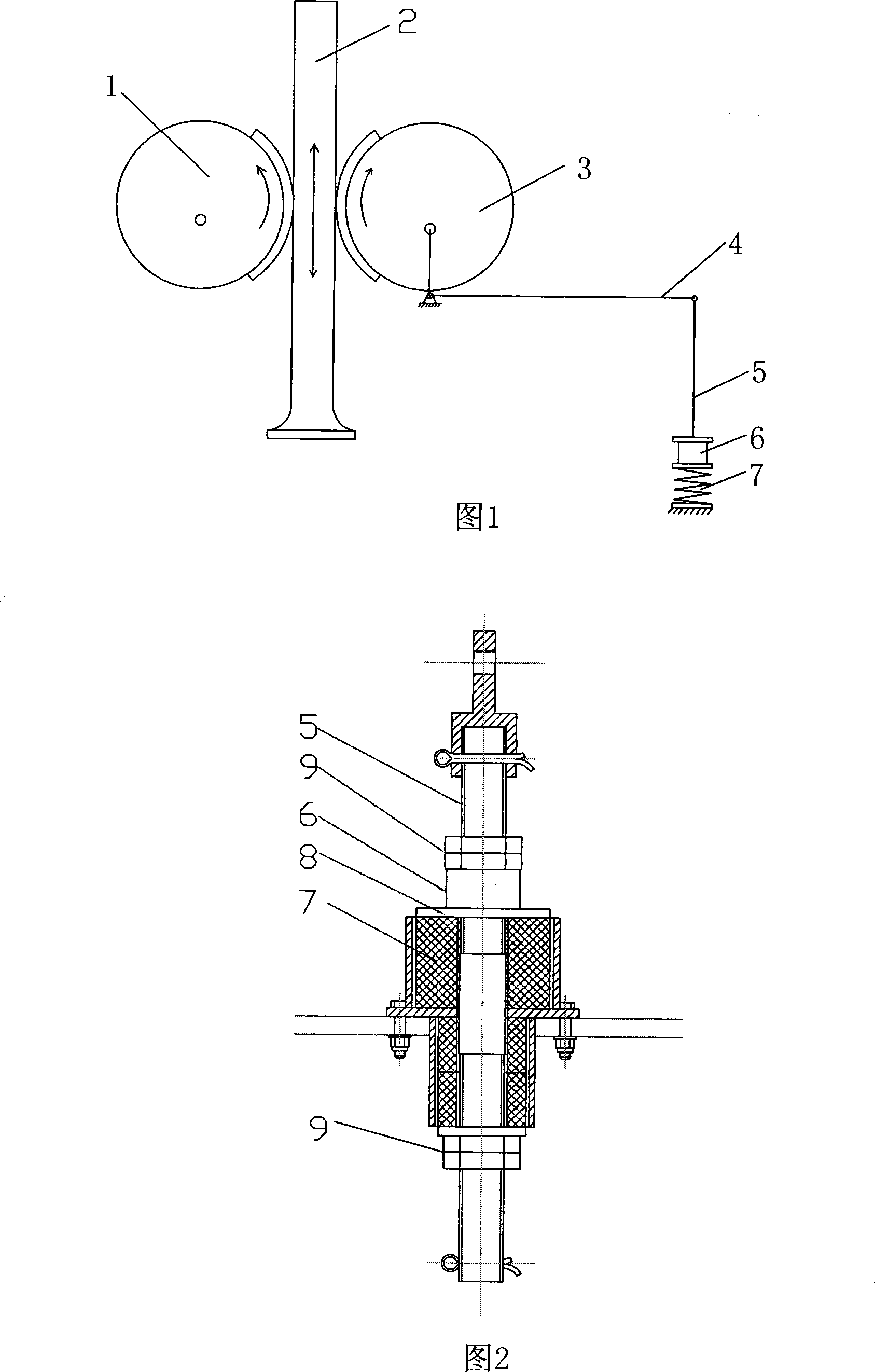

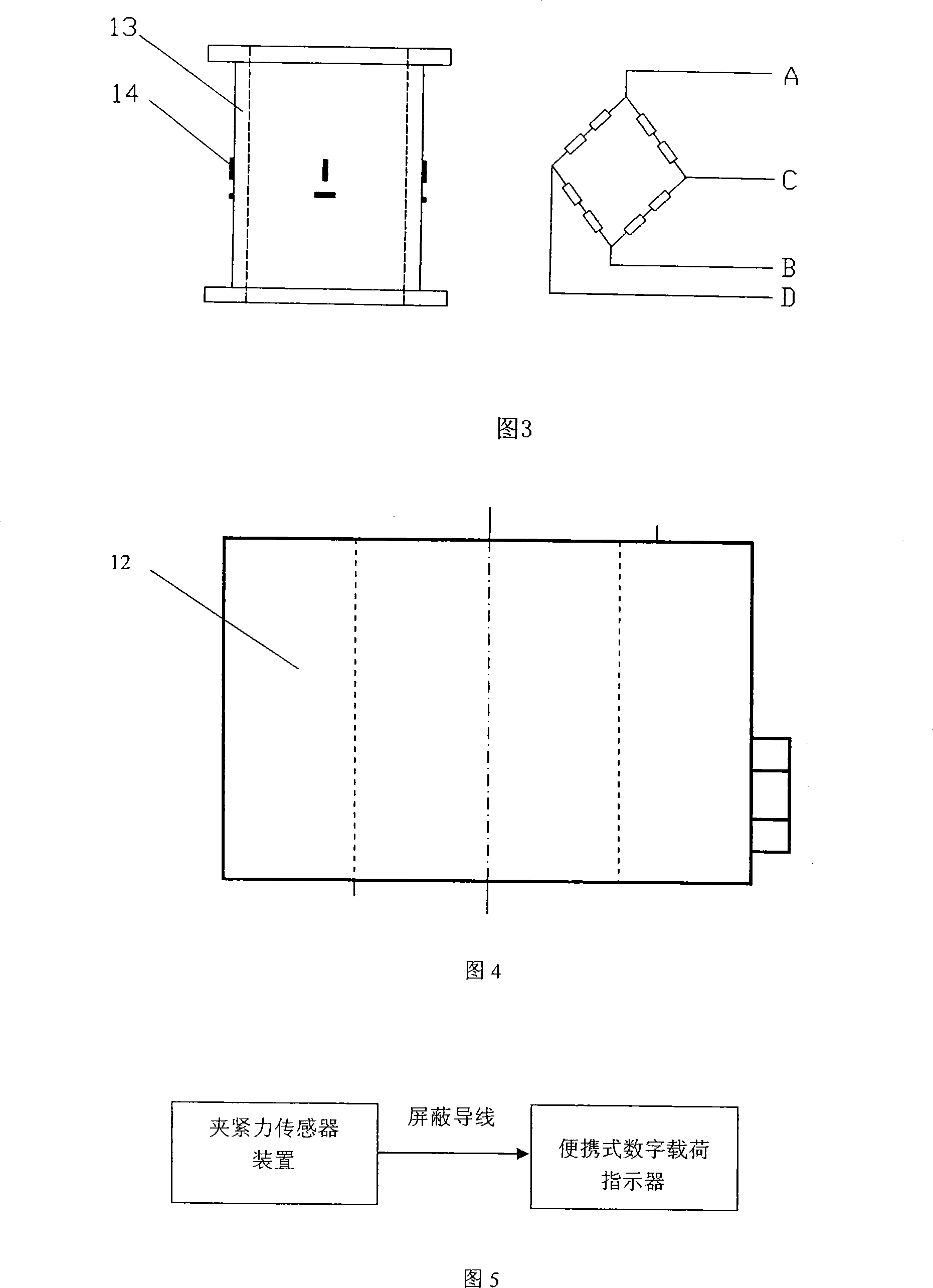

[0018] Figure 1 shows the principle diagram of measuring the clamping force of the hammer rod of the coke oven tamping machine of the present invention; the clamping mechanism of the coke oven tamping machine is a double cam mechanism, one side is a rigid cam 1 mechanism, and the other side is an eccentric cam In the device 3, the eccentric cam device 3 and the pressing device are connected by a lever 4, and the eccentric cam is driven to rotate through a pair of internal and external gears. The clamping force of the eccentric cam generates the clamping force to drive the tamping hammer 2 to move. Among them: the clamping force is provided by the rubber spring 7 in the pressing device, and by adjusting the lock nut 9 on the stud 5, the clamping force of the cam clamping hammer rod can be adjusted.

[0019] Figure 2 shows a schematic diagram of the installati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com