Piezoceramic material, piezoelectric element and non-resonance knock sensor

A piezoelectric sensor, piezoelectric ceramic technology, applied in piezoelectric devices/electrostrictive devices, electrical components, piezoelectric/electrostrictive/magnetostrictive devices, etc., can solve the problem of not displaying temperature characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Hereinafter, the present invention will be described in detail with reference to the accompanying drawings.

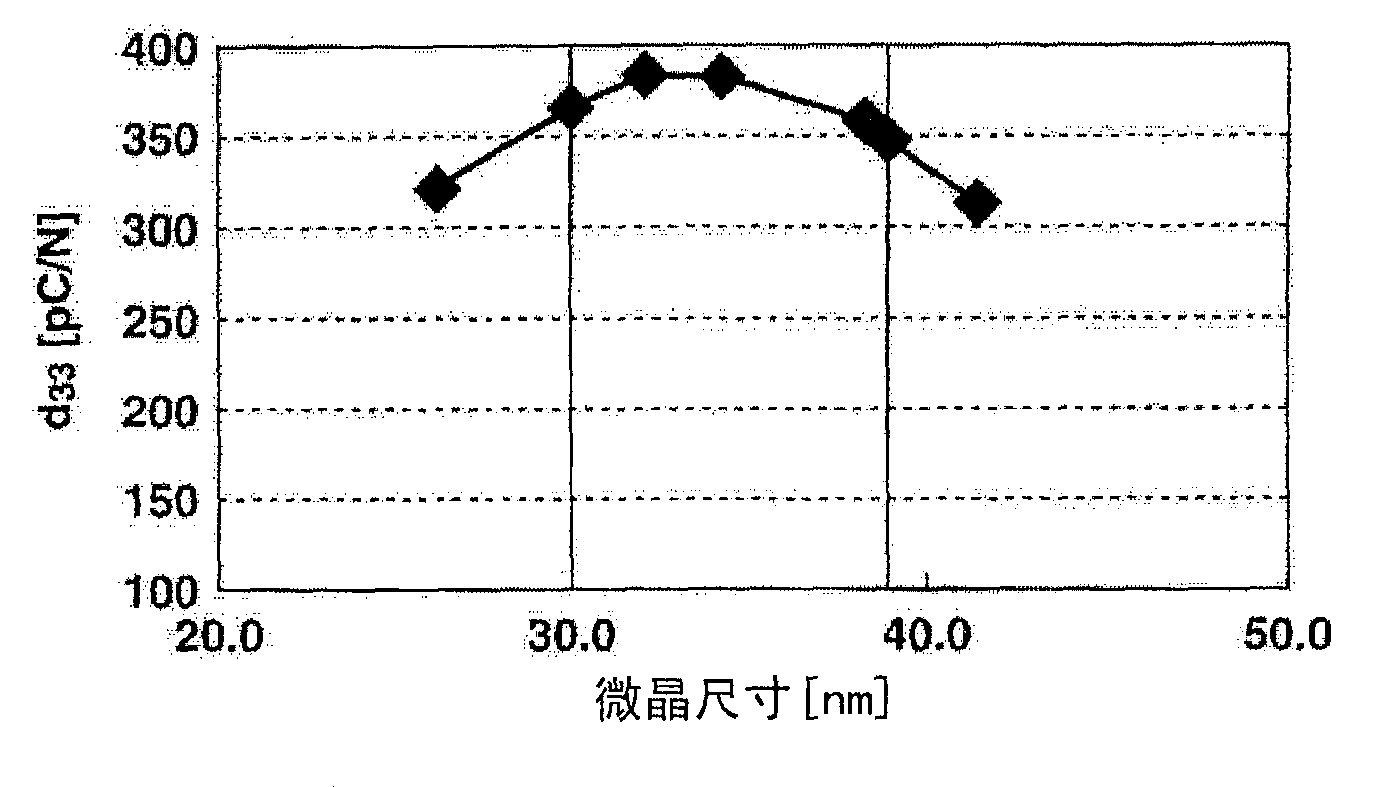

[0022] A piezoelectric ceramic material (hereinafter simply referred to as "piezoelectric ceramic material") according to an exemplary embodiment of the present invention is PZT (PbTiO 3 -PbZrO 3 )ceramics.

[0023] When the tetragonal ferroelectric material PbTiO 3 Zr was substituted for Ti until the amount of Zr in the resulting PZT solid solution reached about 53 mol%, and the crystal structure of the material changed to a rhombohedral structure. This boundary, where the crystal structure of the material changes with composition, is called a metaisomorphic phase boundary (MPB). It is known that the piezoelectricity of the PZT material becomes maximum near the quasi-isomorphic phase boundary, but the stability of the PZT material deteriorates near the quasi-isomorphic phase boundary to cause a large change in capacitance Cp with respect to temperature.

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| piezoelectric charge coefficient | aaaaa | aaaaa |

| Curie point | aaaaa | aaaaa |

| Curie point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com