Mobile car shed roof

A technology for moving carports and roofs, which is applied in the direction of buildings, building types, and buildings where cars are parked. It can solve problems such as damage to mobile carports, snow or rainwater freezing, and heavy burdens on carport frames, so as to increase the service life. The effect of reducing the temperature in the shed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

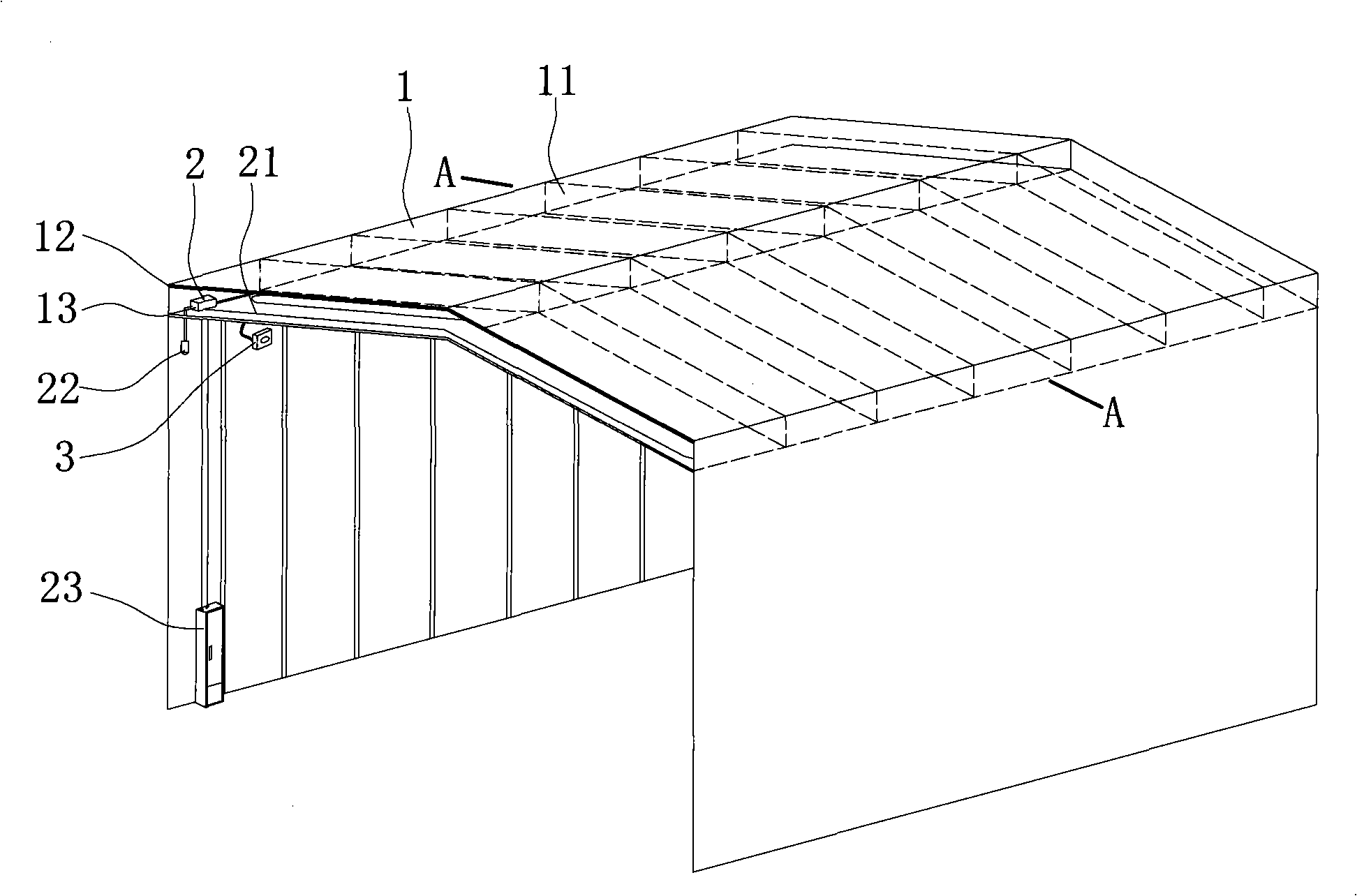

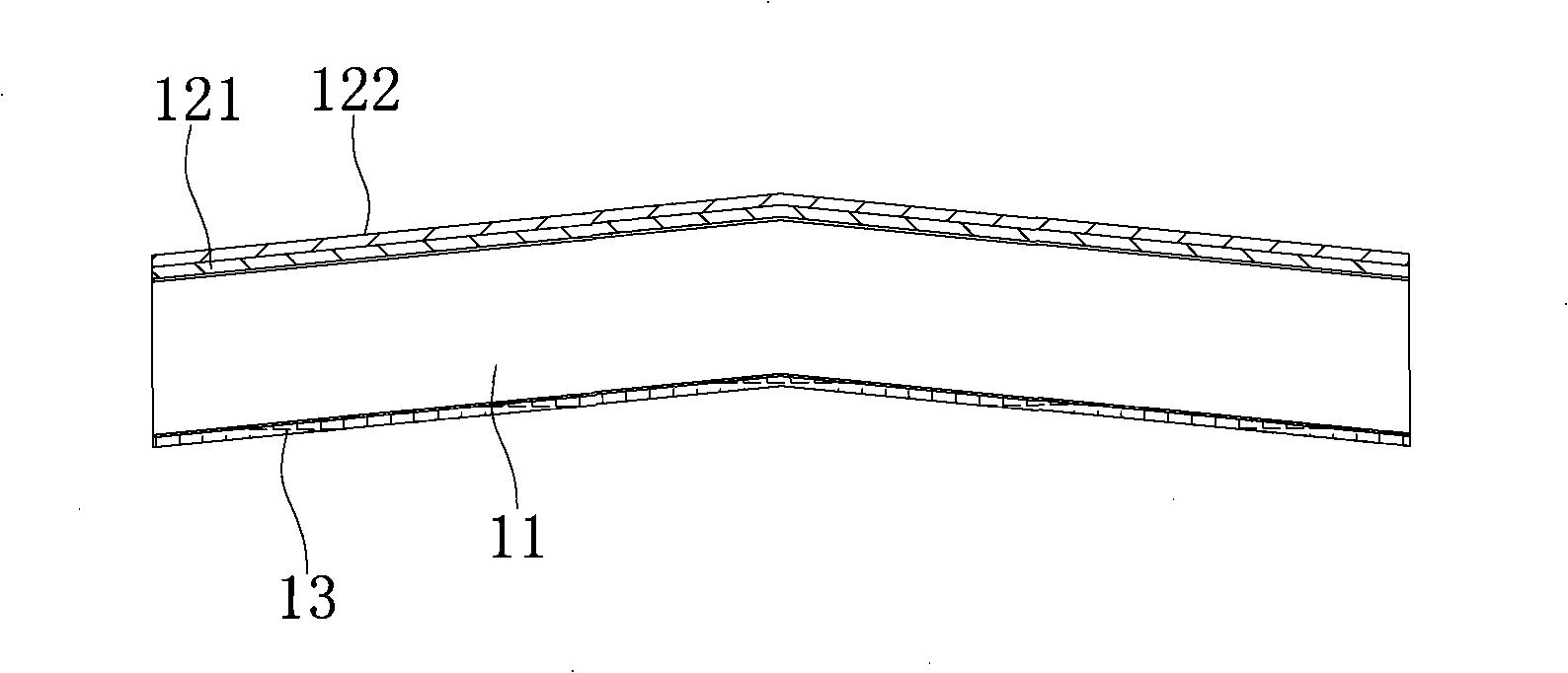

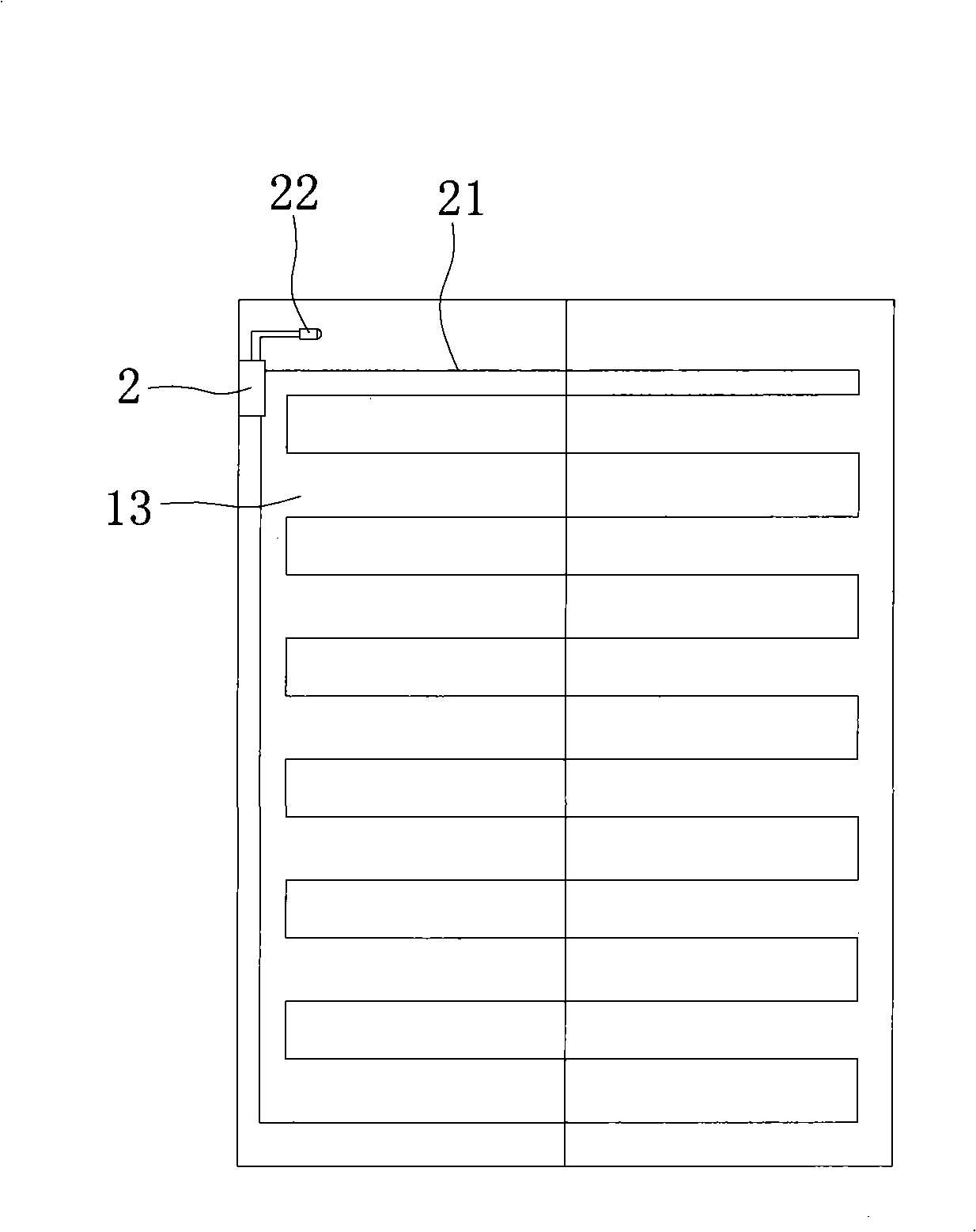

[0017] Such as figure 1 , figure 2 The shown roof of the mobile carport includes a roof body 1 on which an automatic heating mechanism is arranged. The roof body 1 is a double-layer structure, the bottom layer is a heating layer 13, the heating layer 13 is arranged, the upper layer is a ventilation layer 12, and a roof frame 11 is set between the heating layer 13 and the ventilation layer 12. support. A heat insulation space is formed between the heating layer 13 and the ventilation layer 12. The heating layer 13 is a PC heat-resistant insulating layer, and the ventilation layer 12 is composed of a nylon waterproof layer 122 and a PTFE gas-permeable layer 121, and has waterproof and breathable functions at the same time. . Under the scorching sun in summer, the hot air in the shed first gathers in the heat-insulating space and then dissipates outwards. The ventilation layer 12 dissipates a part of the hot air, so that the amount of hot air entering the shed is reduced, and...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap