Centrifugal model retaining wall test device

A technology of test equipment and centrifugal model, applied in the testing of machine/structural components, measuring devices, instruments, etc., can solve the problems of difficult translation, ignoring the influence of gas and oil displacement control, unable to block the static state of the wall, etc. Achieve stable equipment performance, uniform and continuous displacement, and reliable operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The principle, specific structure and working process of the present invention will be further described below in conjunction with the accompanying drawings.

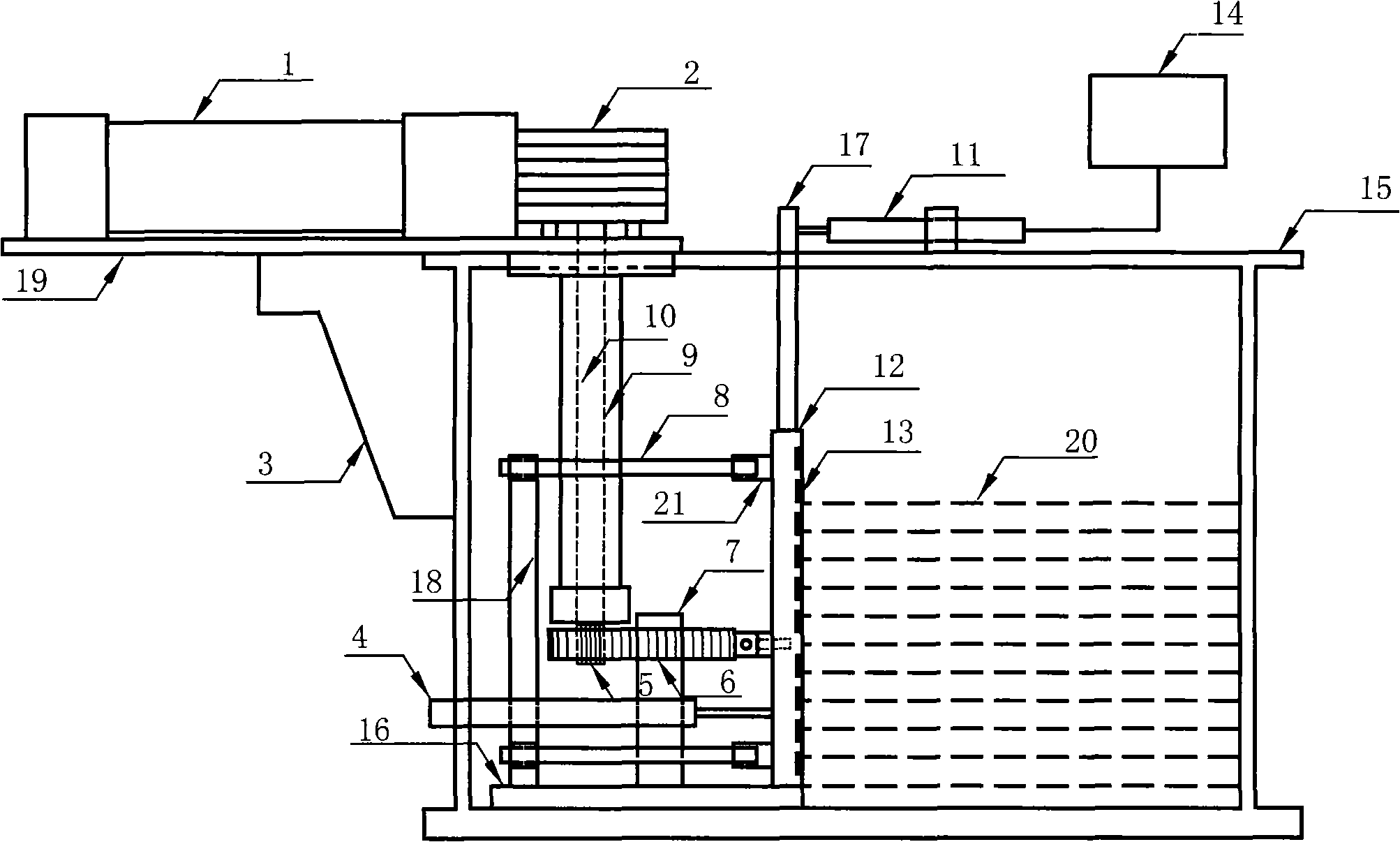

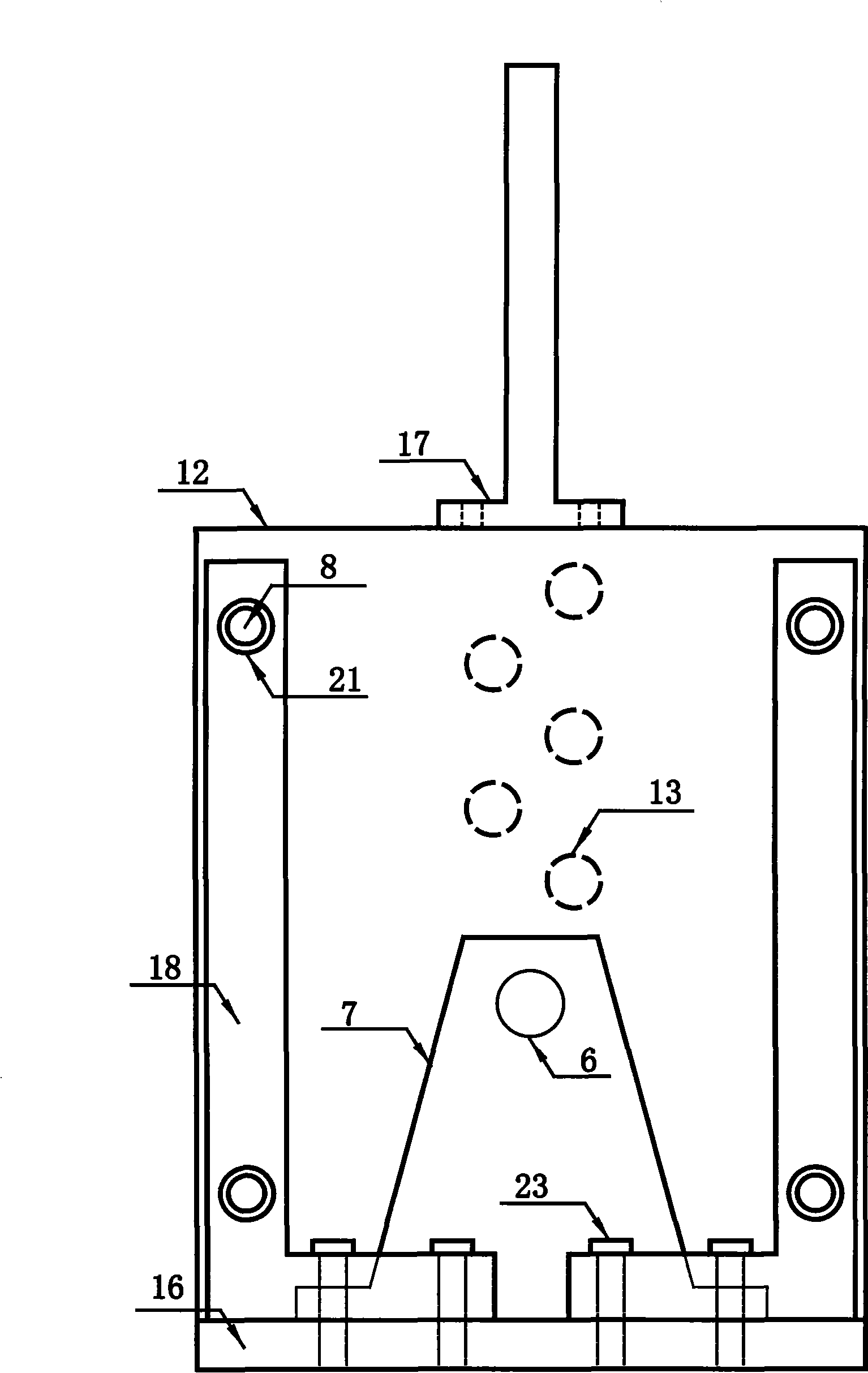

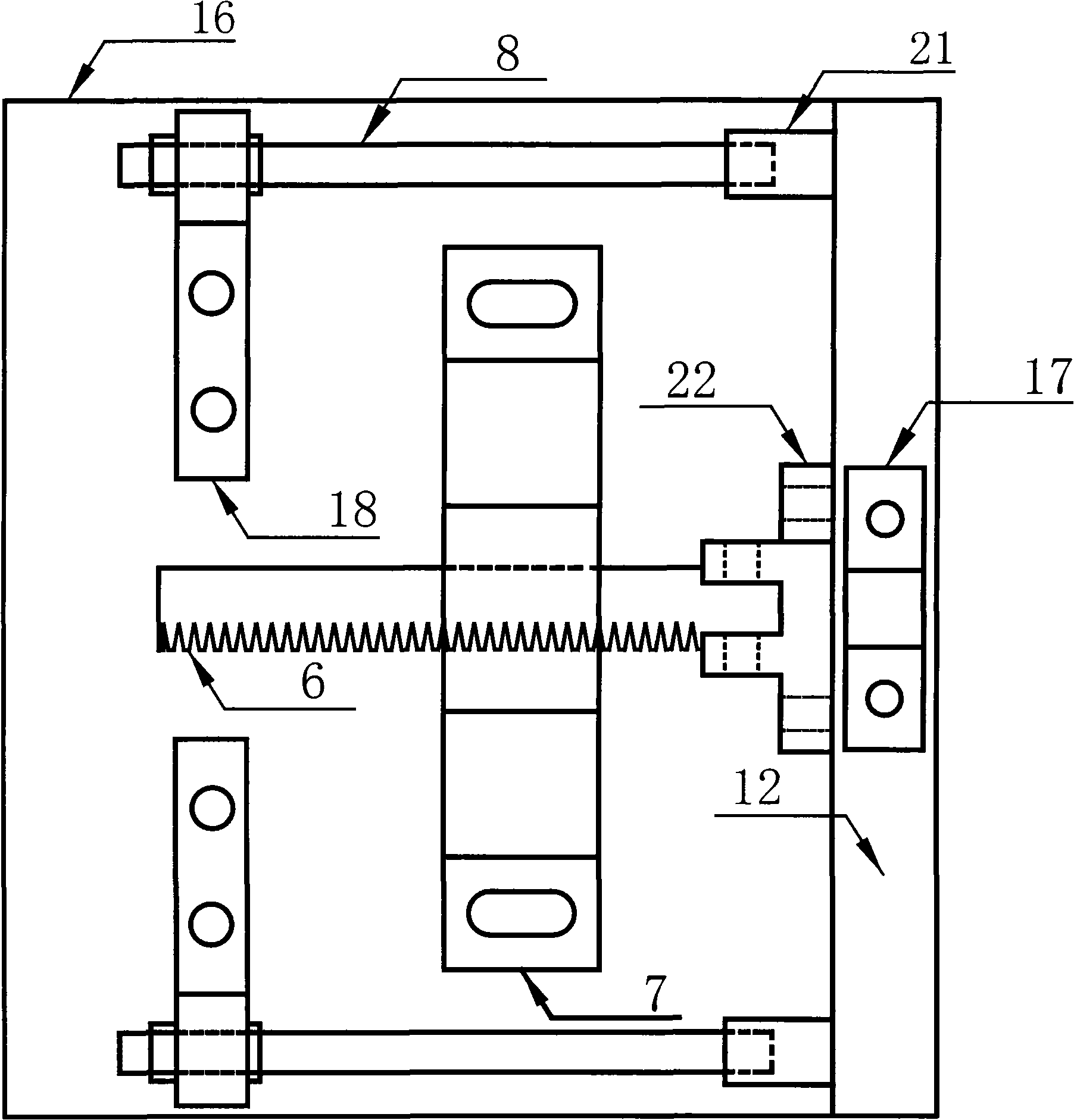

[0019] figure 1 It is a schematic diagram of the principle mechanism of the earth pressure centrifugal model test equipment. The invention mainly consists of four parts: a driving system, a model retaining wall structure, a measuring system and an automatic displacement control system. The following are detailed introductions respectively.

[0020] The drive system includes a motor, a reducer and a transmission mechanism that drives the displacement of the model retaining wall. The transmission mechanism includes a transmission shaft 10, a shaft sleeve 9, a gear 5 and a rack 6. The various components of the drive system are connected and assembled as follows: figure 1 As shown, insert the transmission shaft 10 into the worm gear reducer 2, after adjusting the position of the transmission shaft, fix the transmi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com