Electric connector combination

An electrical connector and contact technology, which is applied in the field of electrical connector assembly, can solve the problems of excessively large component width and poor electrical connector contact.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

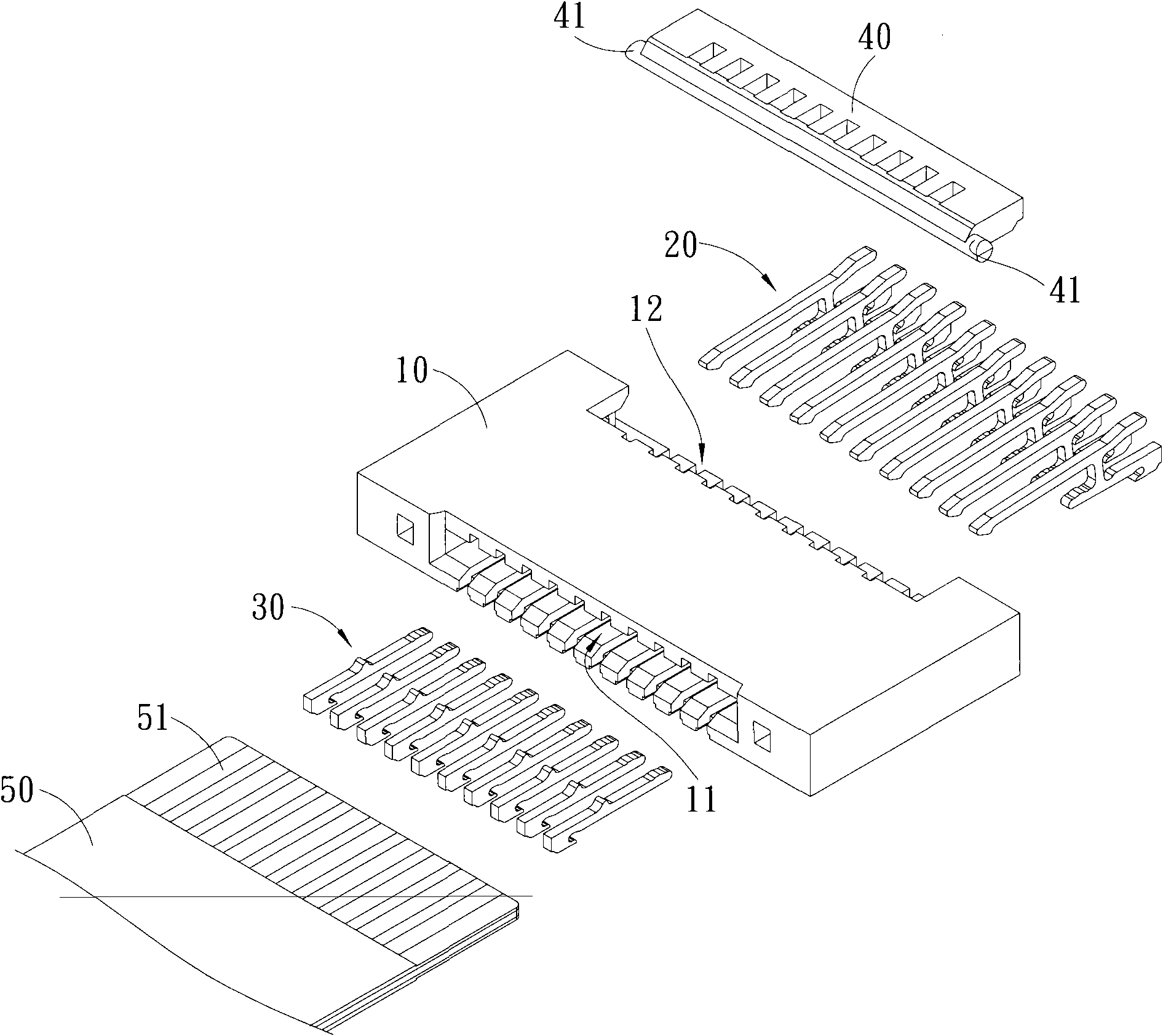

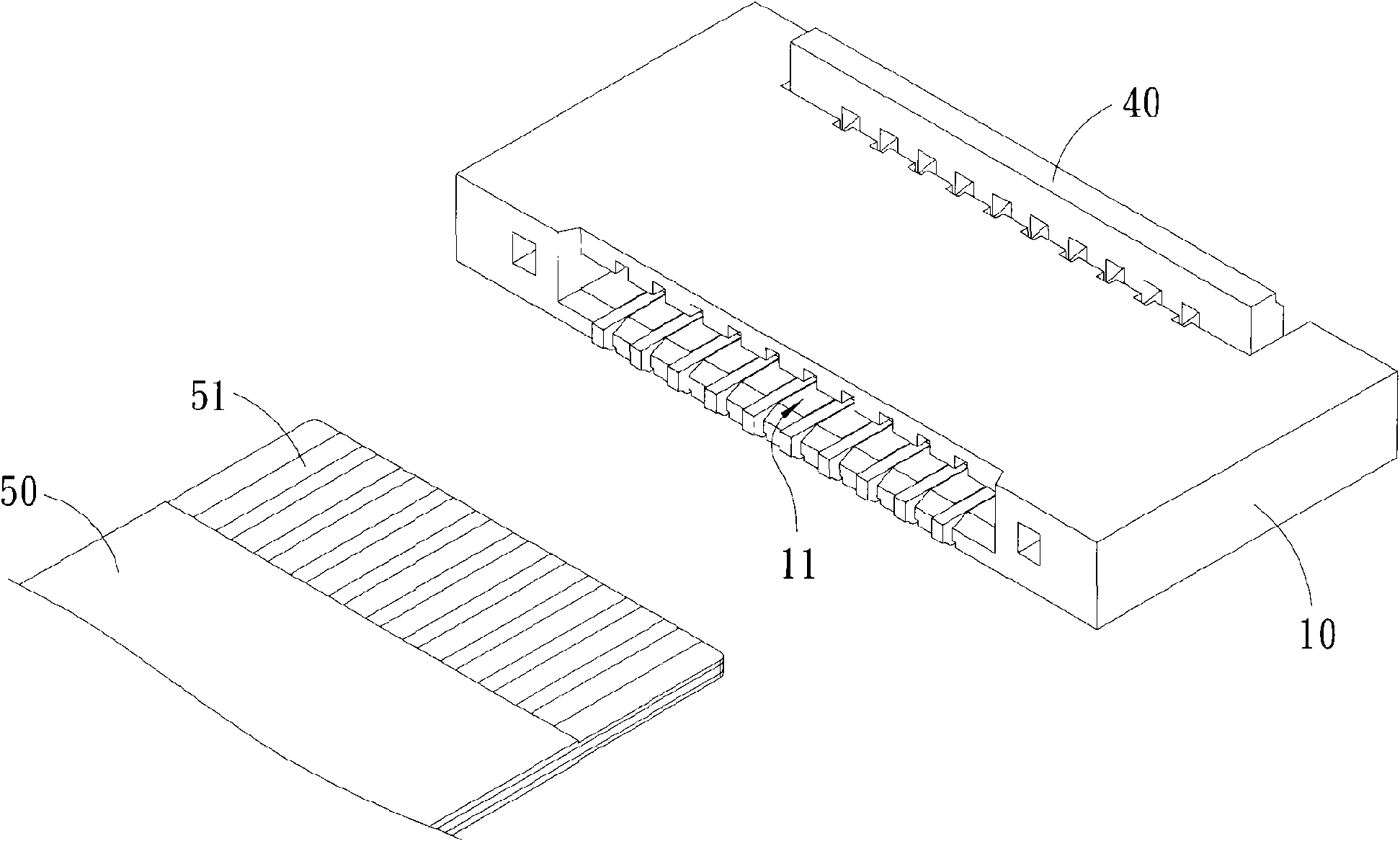

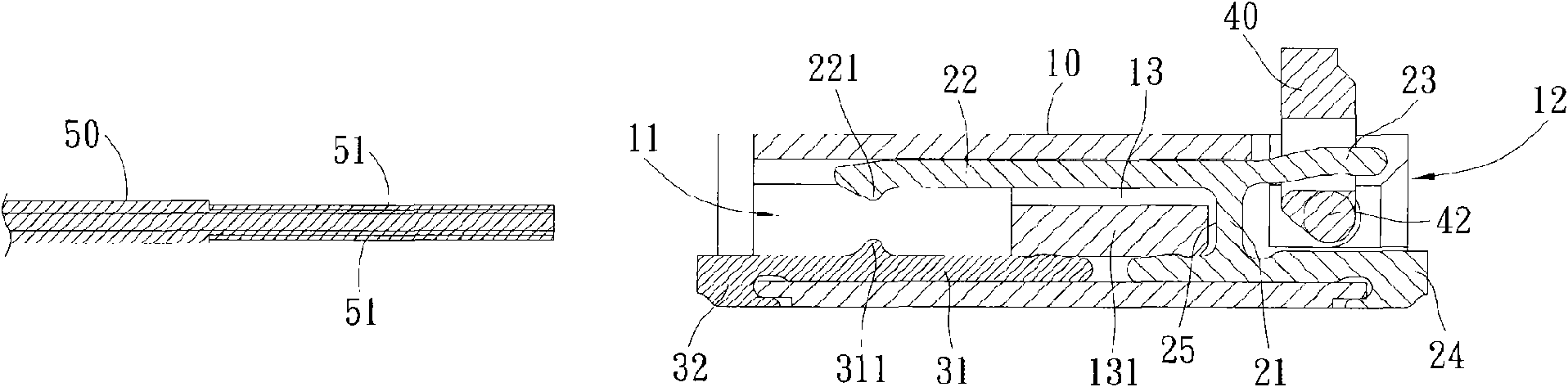

[0029] Please refer to Figure 1 to Figure 4 , are schematic diagrams of preferred embodiments of the present invention. In this preferred embodiment, a flip-back electrical connector is taken as an example for illustration, but the applicable forms of the present invention are not limited to flip-back connectors.

[0030] Please refer to figure 1 and figure 2 Shown is an exploded view and an assembly view of the flip-back electrical connector of this preferred embodiment, which is composed of an insulating body 10, a plurality of first terminals 20, a plurality of second terminals 30 and a rotating member 40 , for connecting the flexible cable 50. The following describes the structural composition of each component:

[0031] The insulating body 10 has a long rectangular structure, and its opposite sides are respectively provided with a front opening 11 and a rear opening 12. The front opening 11 can be inserted into one end of the flexible cable 50. The insulating body 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com