Ultrasonic sensor

一种传感器、超声波的技术,应用在超声波传感器领域,能够解决不能有效地降低余响振动本身等问题,达到好分辨能力、降低余响振动的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

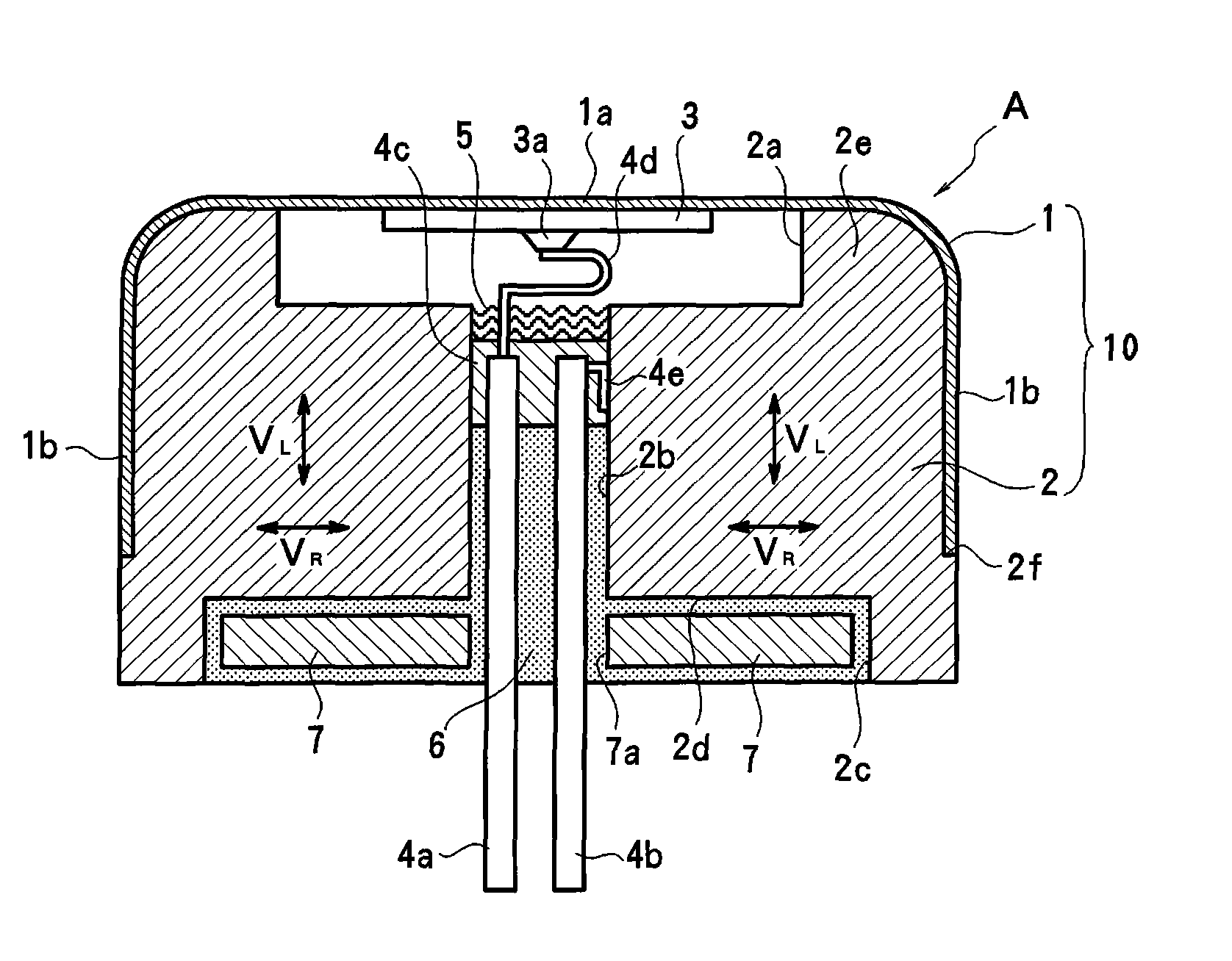

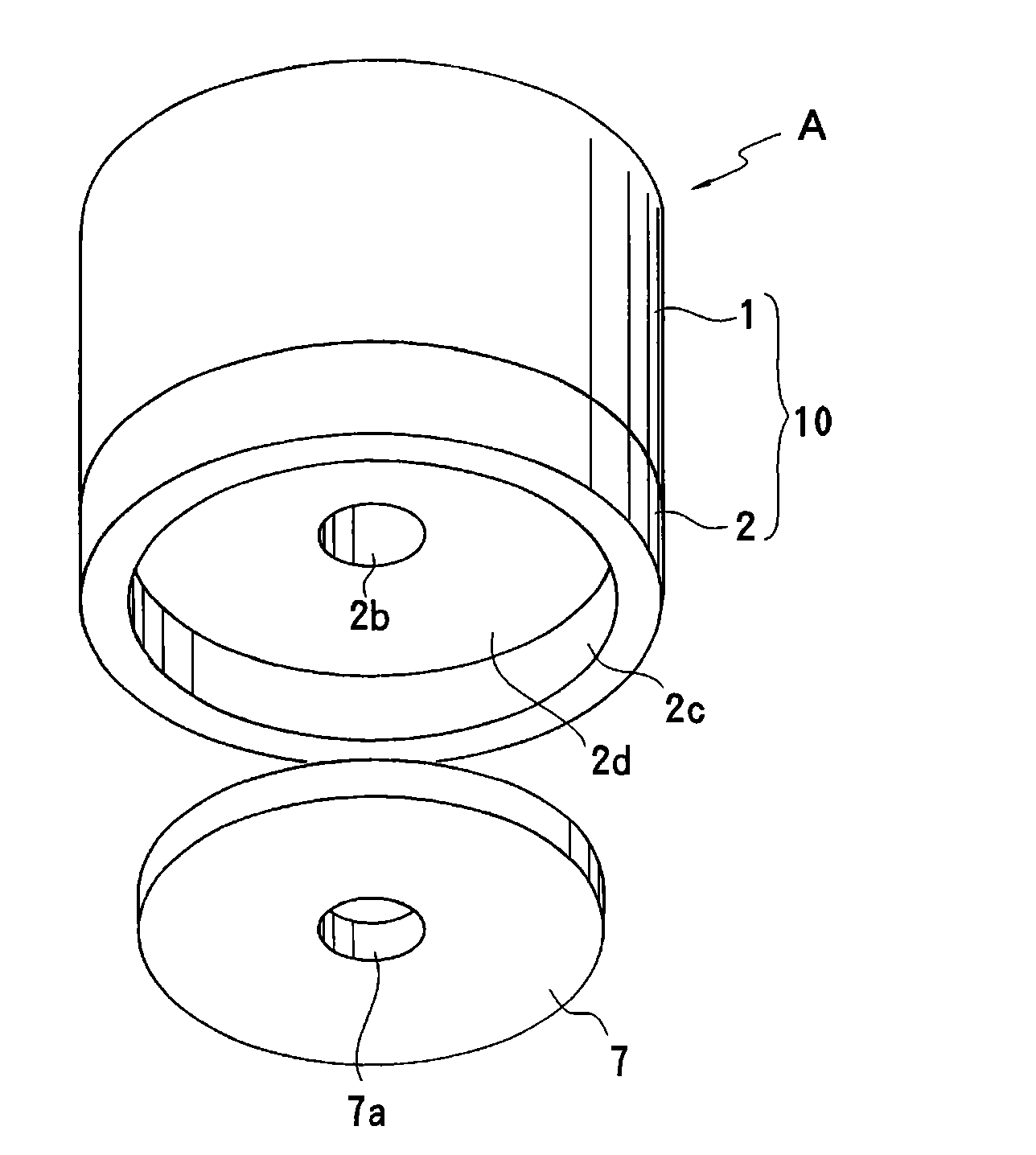

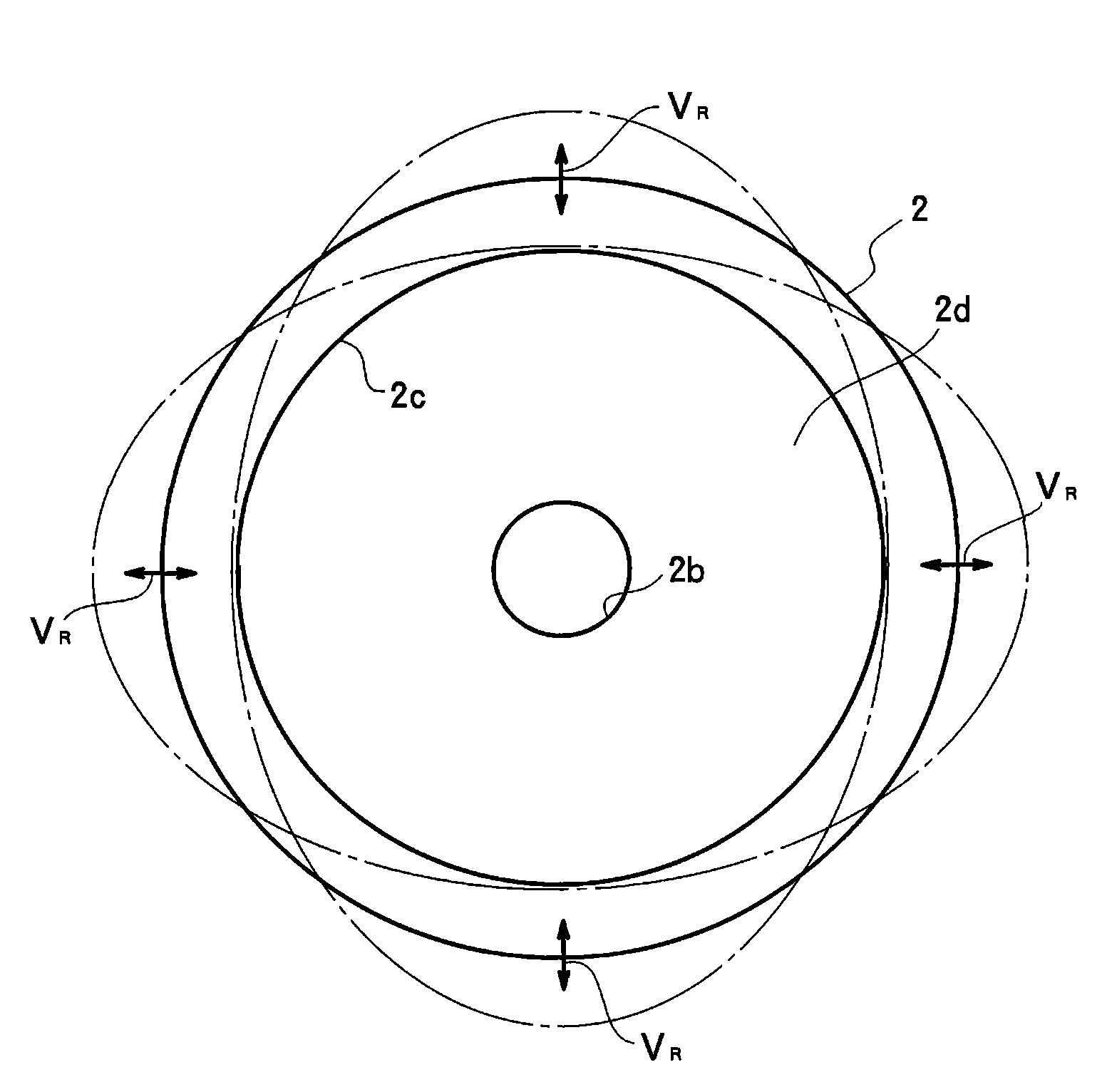

[0063] figure 1 and figure 2 The ultrasonic sensor of Example 1 according to one embodiment of the present invention is shown. This ultrasonic sensor A includes an outer case 1 , an inner case 2 , a piezoelectric element 3 , metal terminals 4 a and 4 b , an acoustic wave absorber 5 , a filler 6 , and a flat member 7 .

[0064] The outer case 1 is formed by punching a metal plate to have a bottomed cylindrical shape (U-shape in cross-sectional view), and a disc-shaped piezoelectric element 3 is fixed to the inside of the bottom 1a of the outer case to constitute a single piezoelectric vibrator. The piezoelectric element 3 includes a piezoelectric ceramic plate and electrodes formed on top and bottom surfaces of the piezoelectric ceramic plate, and when a voltage is applied between the electrodes, the piezoelectric element 3 vibrates in its radial or thickness direction. The outer case 1 includes a cylindrical side wall portion 1b having an opening at a position adjacent to ...

Embodiment 2

[0077] Figure 6 An ultrasonic sensor according to Example 2 of one embodiment of the present invention is shown. In this ultrasonic sensor B, the entire rear surface of the inner case 2A serves as a flat portion 2d on which a flat member 7 is disposed so as to oppose the flat portion 2d with a filler 6 therebetween. The outer diameter of the flat member 7 is substantially the same as that of the inner case 2A. The same components as those in Embodiment 1 are denoted by the same reference numerals, and repeated descriptions are omitted.

[0078] In this embodiment, compared with Embodiment 1, the areas of the inner case 2A and the flat plate 7 facing each other increase toward the outer periphery. Therefore, the shear deformation acting on the filler 6 is more effective. That is, since the deformation of the outer peripheral portion of the flat portion 2d of the inner case 2A is larger than that of the inner peripheral portion thereof, the filler 6 located between the outer...

Embodiment 3

[0080] Figure 7 The ultrasonic sensor of Example 3 according to one embodiment of the present invention is shown. The same components as those in Embodiment 1 are denoted by the same reference numerals, and repeated descriptions are omitted. In the ultrasonic sensor C of the present embodiment, the lead wire 4g is connected to the rear surface of the piezoelectric element 3 fixed to the inner side of the bottom 1a of the outer case 1, and the other lead wire 4h is connected to the inner case 2B The inner surface of the central hole 2d. The lead wires 4g and 4h extend to the outside through the central hole 2b and the through-hole 7a of the plate member 7 . In this embodiment, flat piece 7 is accommodated in recess 2c formed at the rear end of inner case 2B, and filler 6 is filled between flat portion 2d as the bottom surface of concave portion 2c and flat piece 7. When the inner shell 2B vibrates, relative deformation occurs between the inner shell and the flat member 7, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com