Threshing apparatus

A threshing and drum technology, applied in threshing equipment, agriculture, applications, etc., can solve the problems of deterioration of threshing efficiency and easy retention of untreated materials in the drum chamber, and achieve the effect of improving threshing efficiency and reducing the opening rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0058] Hereinafter, 1st Embodiment of the threshing apparatus which concerns on this invention is demonstrated referring drawings.

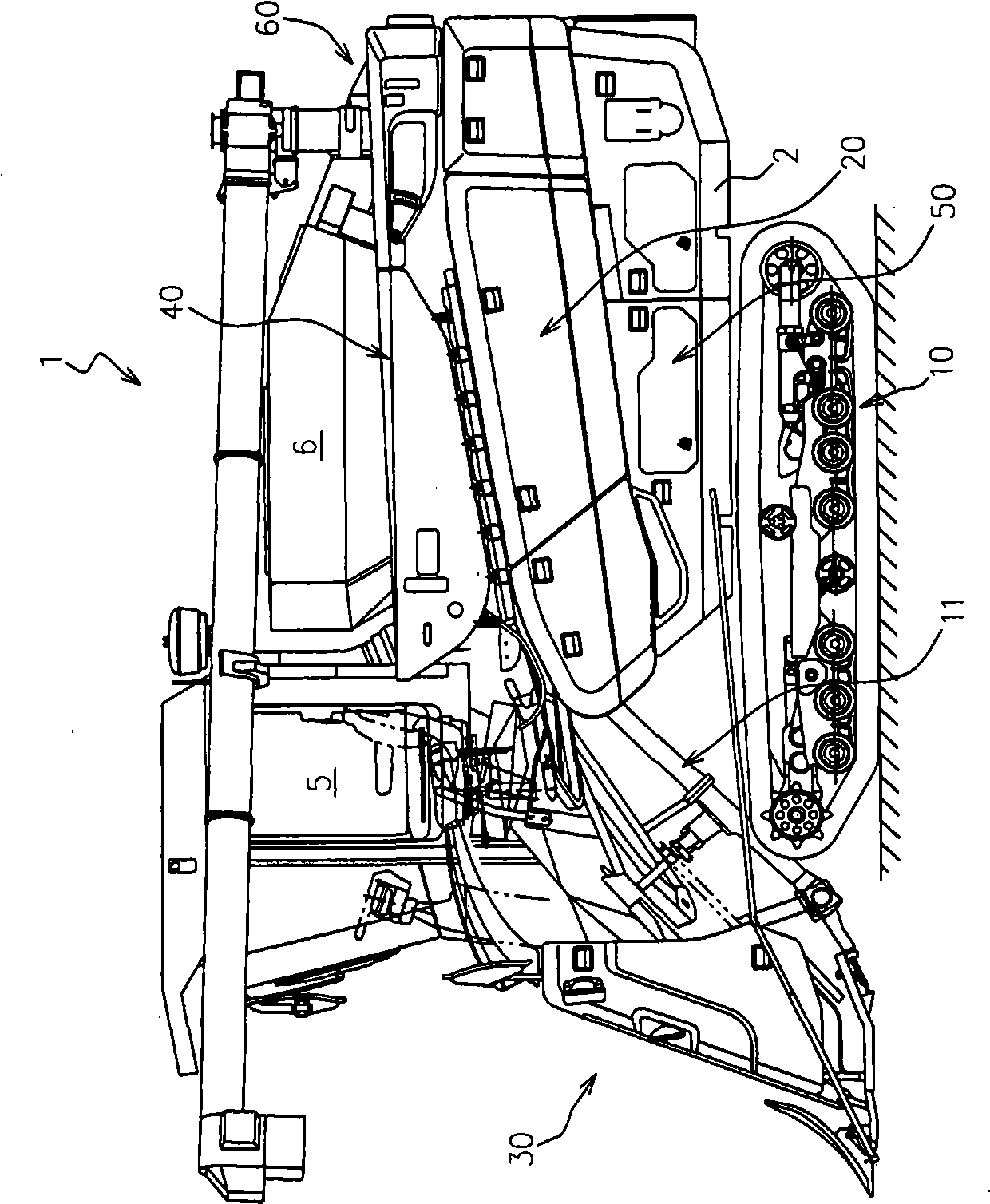

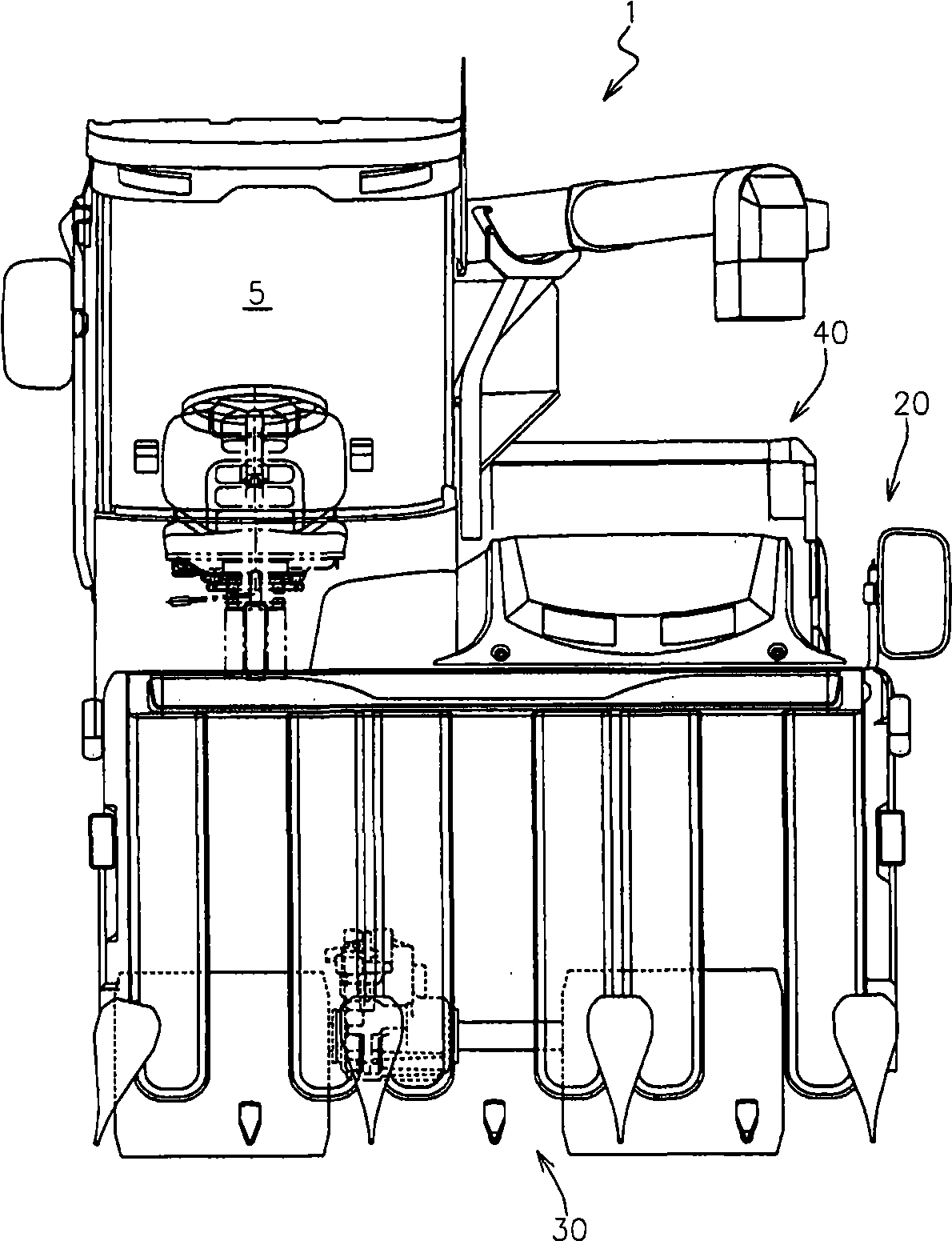

[0059] figure 1 and figure 2 It is a left side view and a top view of the combine 1 to which the threshing apparatus concerning 1st Embodiment was applied.

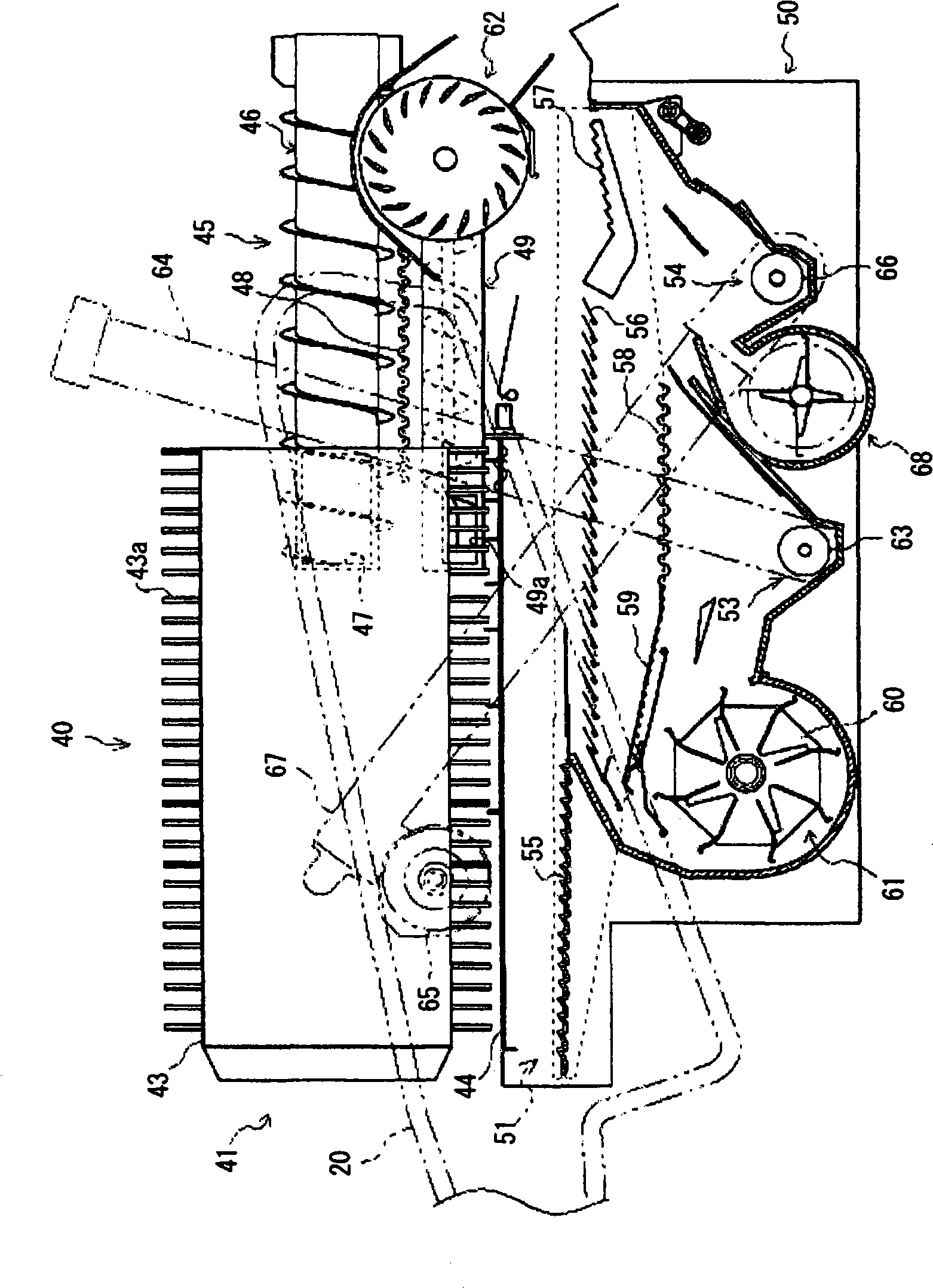

[0060] Such as figure 1 and figure 2Shown, above-mentioned combine harvester 1 possesses: main frame 2; Engine (not shown) as the power source supported on the above-mentioned main frame 2; It is a crawler-type traveling device) 10; in front of the above-mentioned main frame 2, a harvesting device 30 that is arranged on a harvesting frame 11 liftably supported on the main frame 2; 2, the feeding chain device 20 conveyed in the rear direction of the left side; the threshing device 40 arranged on the left part of the above-mentioned main frame 2 so as to carry out threshing treatment to the straw conveyed by the above-mentioned feeding chain device 20; The sorting device 50 below the ab...

Embodiment approach 2

[0133] The threshing apparatus 40B which concerns on 2nd Embodiment of this invention is demonstrated below.

[0134] Figure 6 It shows the front schematic view of the threshing apparatus 40B which concerns on this 2nd Embodiment, Figure 7 express Figure 6 Shown is an expanded view of the receiving wire 44B in the above threshing device. In addition, in Figure 7 In , the positional relationship among the said receiving net 44B, the threshing cylinder 43, and the dust-feeding port processing cylinder 46 is shown together.

[0135] In addition, in the drawings, the same reference numerals are assigned to the same components as those in the above-mentioned first embodiment, and their detailed descriptions are appropriately omitted.

[0136] In this embodiment, if Figure 6 and Figure 7 As shown, the above-mentioned receiving net 44B is equipped with: viewed in the direction of the rotation axis of the threshing cylinder 43, it is made into an arc shape so as to cover t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com