Threshing cylinder of corn thresher

A technology of threshing drums and threshing machines, applied in threshing equipment, agricultural machinery and implements, applications, etc., can solve the problems of corn kernels remaining on the corn cob, corn cobs cannot be threshed, and threshing efficiency becomes low, so as to improve the threshing ability , Thorough threshing, and the effect of improving threshing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

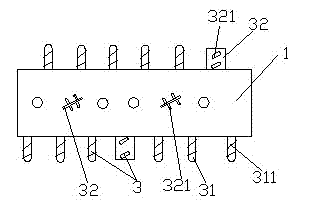

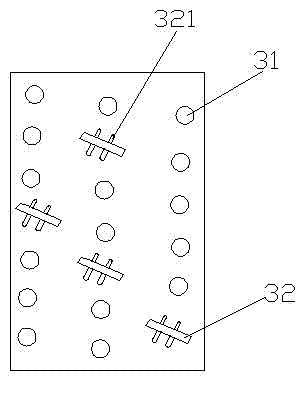

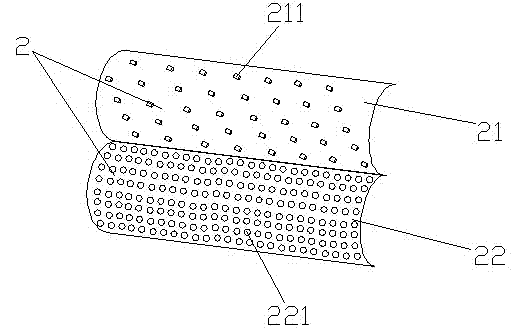

[0014] like Figure 1 to Figure 3 As shown, an embodiment of the present invention includes a roller body 1 and a sieve body 2, the roller body 1 is horizontally arranged in the sieve body 2, the roller body 1 rotates in the sieve body 2 through a power transmission device, and the sieve body 2 is fixedly arranged in the threshing On the machine, the installation of the roller body 1 and the sieve body 2 and the setting of the discharge port on the sieve body 2 are all well-known technologies of those skilled in the art, and will not be repeated here; in this embodiment, the roller body 1 is set There are threshing teeth 3, and the threshing teeth 3 are distributed in a single helix from the first to the last one. The threshing teeth 3 include cylindrical teeth 31 and blade teeth 32. The blade teeth 32 are rectangular plates, and the blade teeth 32 are along the spiral line. The direction is inclined, that is, its bottom is fixed on the roller body 1 along the helix, but it is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com