A hose depoling method and a device thereof

A rubber tube and core removal technology, which is applied in the field of rubber tube core removal methods and devices thereof, achieves the effects of solving core removal difficulties, high efficiency and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The high-pressure medium in this embodiment is high-pressure gas.

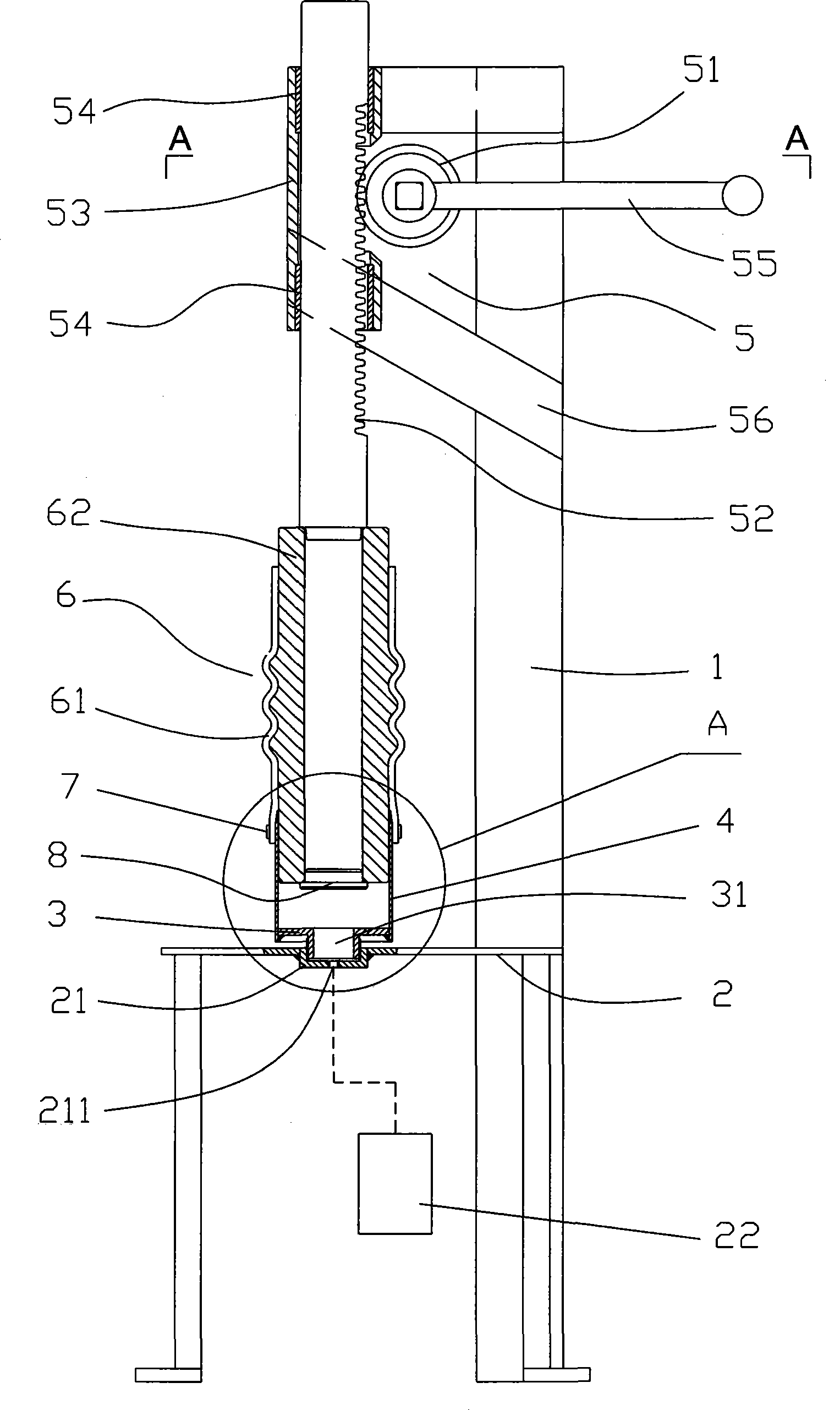

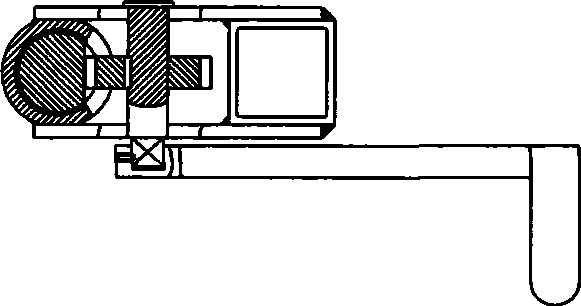

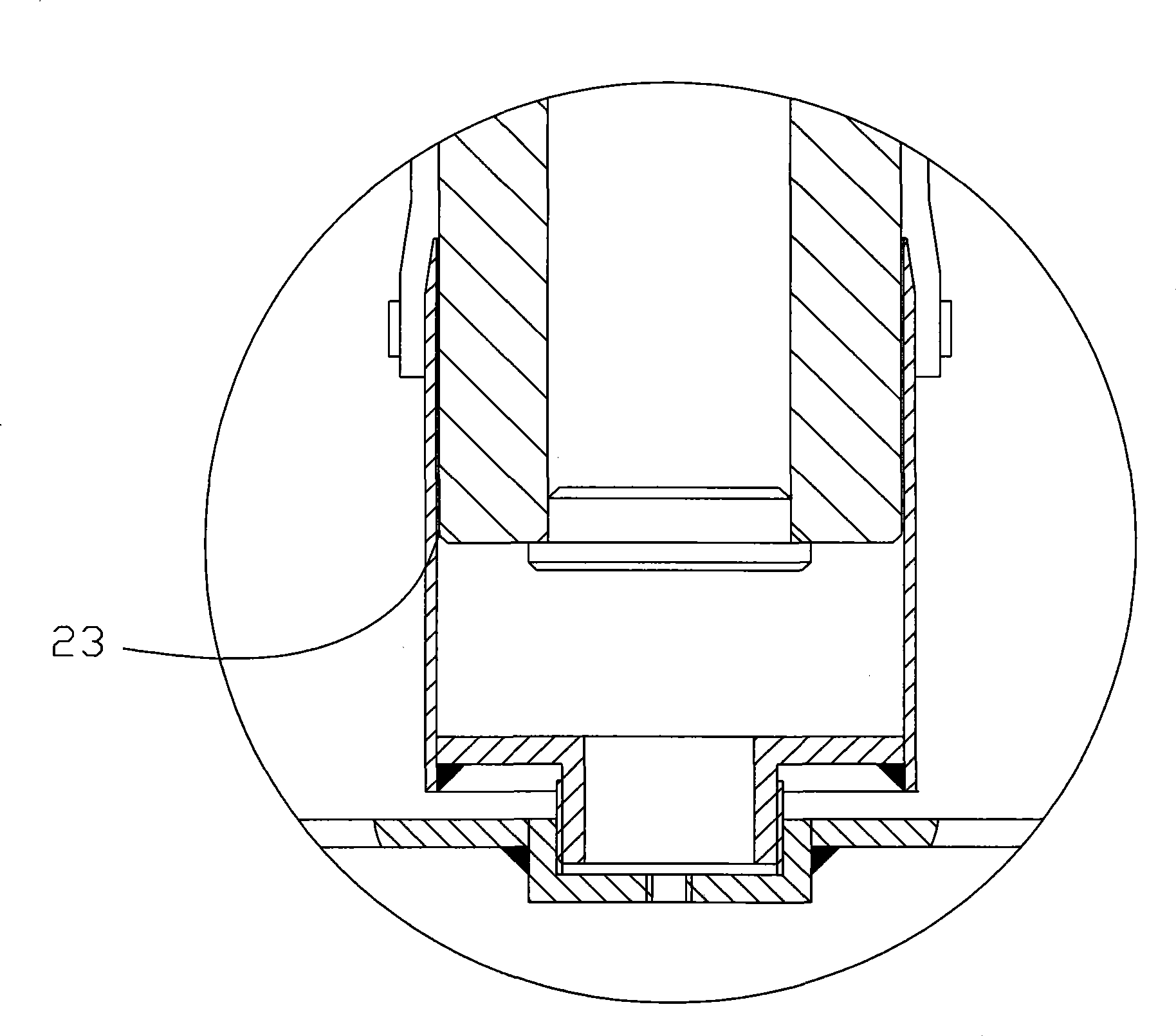

[0024] Such as figure 1 , figure 2 , image 3 As shown, the rubber hose coring device of the present invention includes a support 1 and a high-pressure medium source 22. The lower part of the support 1 is provided with a support base 2, the end surface of the support base is provided with a groove 21, and the middle part of the groove is provided with an air inlet 211. ; The groove 21 is equipped with a chuck 3 that is compatible with it, and the groove 21 and the chuck 3 constitute a support device for a rubber hose with a core, and the support device is used to support the molded rubber hose 6 with a core; The head 3 is airtightly connected with the groove 21 , a central air hole 31 is provided on the chuck 3 , and an annular plug 4 is sealed and connected to the upper end of the chuck 3 . A molding device 5 is arranged above the bracket 1 , a rubber hose with a core 6 is vertically arranged betwe...

Embodiment 2

[0029] The high-pressure medium in this embodiment is high-pressure water.

[0030] Such as Figure 4 , Figure 5 As shown, the rubber hose coring device of the present invention includes a workbench 9 and a water pump 10. The workbench 9 is relatively provided with a support side plate 20 and a protection side plate 21. The support device 11 is horizontally arranged on the support side plate 20, with a mold core The rubber hose is arranged between the supporting side plate 20 and the protecting side plate 21 , and the supporting device 11 and the supporting side plate 20 are fixedly connected by nuts 12 .

[0031] The right end of the support device 11 is sealed and connected with the left end of the ring plug 13, the support device 11 and the ring plug 13 are hollow pipe structures, the left end of the support device 11 is the water inlet, the output end of the water pump 10 is connected to the support device 11 The left end is connected; the right end of the annular plug ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com