Screen installation and leveling tool and screen installation and leveling method

A technology for leveling tools and screens, which is applied in the direction of manufacturing tools, hand-held tools, etc., can solve the problems of screen height difference and affect the use, and achieve the effect of eliminating height difference, reasonable design, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

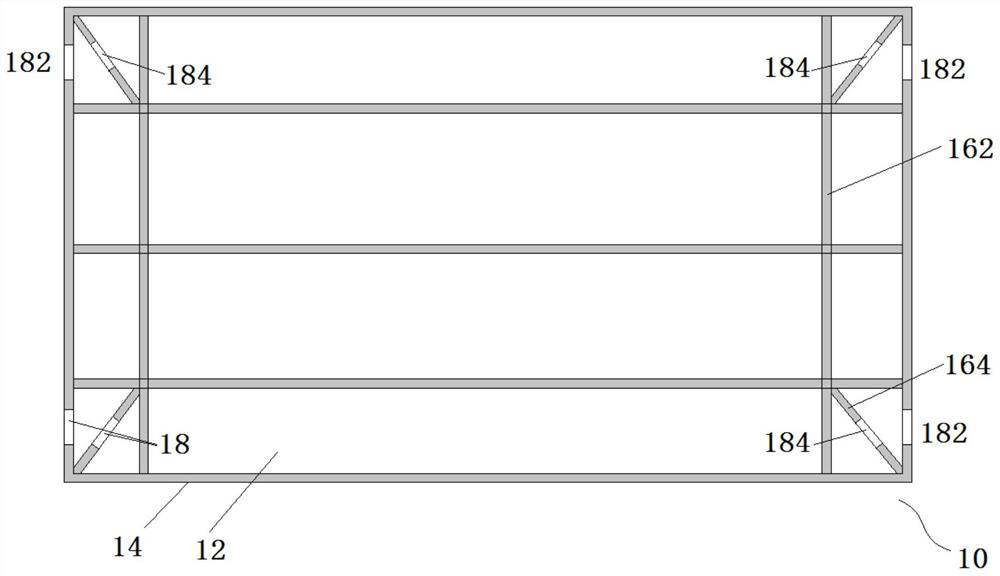

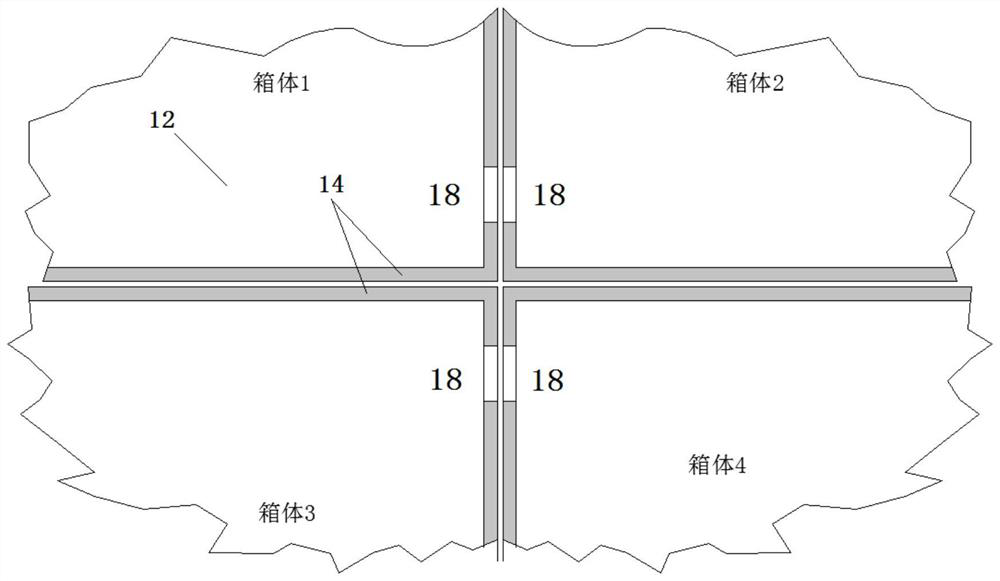

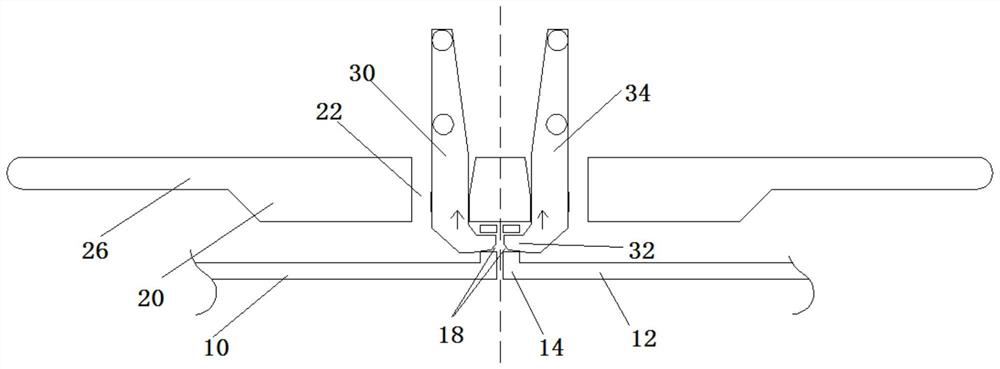

[0028] The embodiment of the present invention provides a screen installation leveling tool, please refer to image 3 , image 3 It is a working diagram of the screen installation leveling tool according to Embodiment 1 of the present invention. As shown in the figure, the screen installation leveling tool includes a leveling base plate 20 and at least two hooks 30, and the leveling base plate 20 includes a first surface and a second surface. Two sides, wherein the first side is a plane. At least two second through holes 22 are opened on the leveling substrate 20, and the second through holes 22 are arranged in pairs; the pull hook 30 includes a fixedly connected hook portion 32 and a pulling portion 34; when the screen installation leveling tool is in the In the working state, the leveling substrate 20 is located above the LED box 10 and the first surface is facing the side of the LED box 10, and the hook 32 can pull the LED box 10 to move up and make the top surface of the ...

Embodiment 2

[0032] Please refer to Figure 4-5 , Figure 4 It is a working schematic diagram of the screen installation and leveling tool described in Embodiment 2 of the present invention, Figure 5 It is a schematic diagram of the unhooking operation of the screen installation and leveling tool described in Embodiment 2 of the present invention. The screen installation leveling tool according to Embodiment 2 of the present invention includes a leveling base plate 20 , at least two pull hooks 30 , a first pressing rod 40 and at least two hinged supports 24 . At least two second through holes 22 are opened on the leveling substrate 20 , and the second through holes 22 are arranged in pairs. As a preferred implementation mode, in this embodiment, the number of the second through holes 22 is two.

[0033] The draw hook 30 includes a fixedly connected hook portion 32 and a pull portion 34 , the hook portion 32 can pull the LED box 10 to move up and down, and the pull portion 34 can move up...

Embodiment 3

[0039] Please refer to Figure 6 , Figure 6 It is a schematic diagram of the working structure of the screen installation and leveling tool described in Embodiment 3 of the present invention. As shown in the figure, the embodiment of the present invention provides a screen installation leveling tool, which is different from Embodiment 2 in that it also includes a second pressing rod 50, and the second pressing rod 50 includes at least two second pressing rod bodies 52, the second pressing rod body 52 is fixedly connected with the pulling part 34, by pulling up the second pressing rod body 52, that is, each pair of second pressing rod bodies 52 exerts a force toward the direction of approaching each other, and then passes through the pulling part 34 exerts a force to compress the elastic member 28 , so that the hook portion 32 escapes from the first through hole 18 . The second pressing rod 50 and the first pressing rod 40 cooperate with each other, so that the insertion and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com