Disengaging method and device of anti-roll torsion bar sleeved in arm sleeve of torsion arm

A technology of anti-rolling torsion bar and torsion arm, which is applied in the field of rail transportation, and can solve the problems such as difficult to disengage the torsion arm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

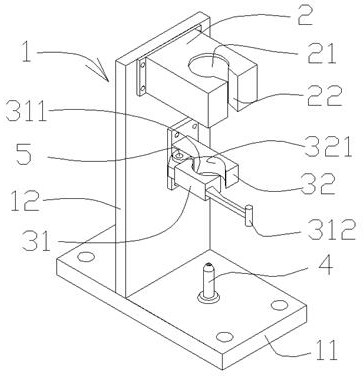

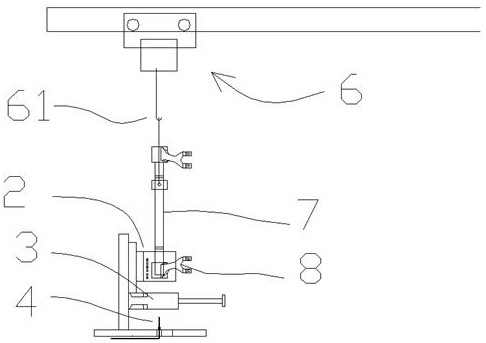

[0025] The present invention will be further described below in conjunction with accompanying drawing:

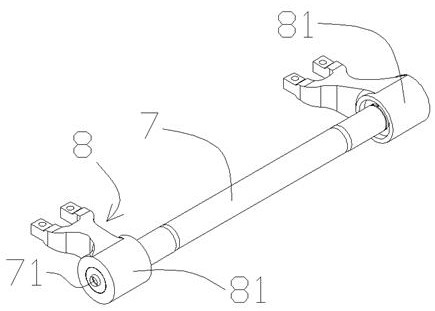

[0026] like image 3 , 4 As shown, a method for removing the anti-roll torsion bar set in the torsion arm sleeve is to first heat the arm sleeve 81 of the torsion arm 8 set at the end of the torsion bar 7 to a set temperature, so that the torsion arm 8 The arm cover 81 produces thermal expansion, and then rapidly cools the end portion of the torsion bar 7 that is enclosed within the arm cover 81 and causes the arm cover 81 to be contracted by cold and loosen from the torsion bar 7 ends. Because the arm cover 81 also conducts heat to the torsion bar 7 during heating, cooling the torsion bar end in the arm cover 81 is exactly to form the contrast that the arm cover 81 produces thermal expansion and the torsion bar end produces cold contraction, so that the arm cover 81 and the torsion bar end produce cold contraction. A gap is formed between the ends of the torsion bar, so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com