Precise needle head with anti-collision function

A functional and precise technology, applied in the field of precision needles, can solve the problems of cumbersome operation of finished solder paste, time-consuming and laborious, and easy deviation of precision tin-pointing needles.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

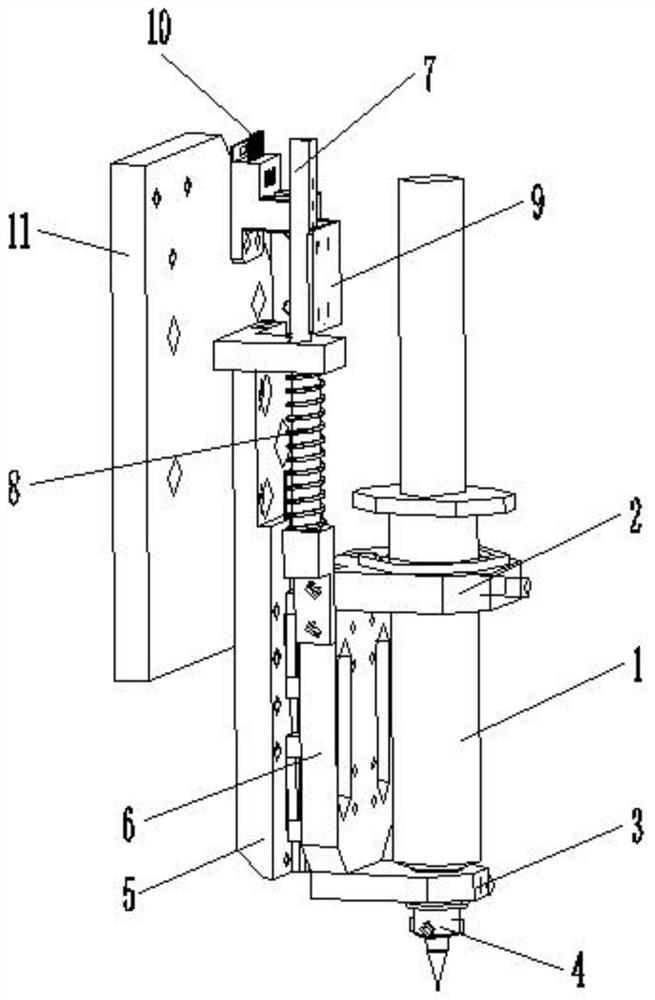

[0034] On the basis of the above structure, in this embodiment, the sealing member is a locking screw 2 , and the lower end of the locking screw 2 is screwed to the upper end of the tin pot 1 . The locking screw 2 is threadedly connected with the upper end of the tin filling cylinder 1, which facilitates the opening and closing of the tin filling cylinder 1, which is easy to operate, saves time and effort, and greatly improves production efficiency.

[0035] The above-mentioned locking screw 2 acts as a seal, that is, the upper end of the tin filling cylinder 1 is provided with an internal thread, and the lower end of the locking screw 2 is threadedly connected with the upper end of the tin filling cylinder 1 to seal the upper end of the tin filling cylinder 1 .

Embodiment 2

[0037] On the basis of the above structure, in this embodiment, the sealing member is a sealing cover, and the sealing cover is screwed to the upper end of the tin pot 1 . The sealing cover is threadedly connected with the upper end of the tin filling cylinder 1, so that the opening and closing of the tin filling cylinder 1 is convenient, the operation is simple, time-saving and labor-saving, and the production efficiency is greatly improved.

Embodiment 3

[0039] On the basis of the above structure, this embodiment also includes a horizontally arranged bottom plate 3 that can move up and down. The tin filling tube 1 is fixed on the bottom plate 3 by welding or bolts, and the tin filling tube 1 is installed through the bottom plate 3 to increase the tin filling tube. 1 The stability of installation and up and down movement.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com