Faraday polarization apparatus

A technology of Faraday rotator and magneto-optical rotation, which is applied in the direction of instruments, optics, nonlinear optics, etc., and can solve problems such as difficulty in consistency of combined magnetic field, failure to work, high magnetic field strength, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

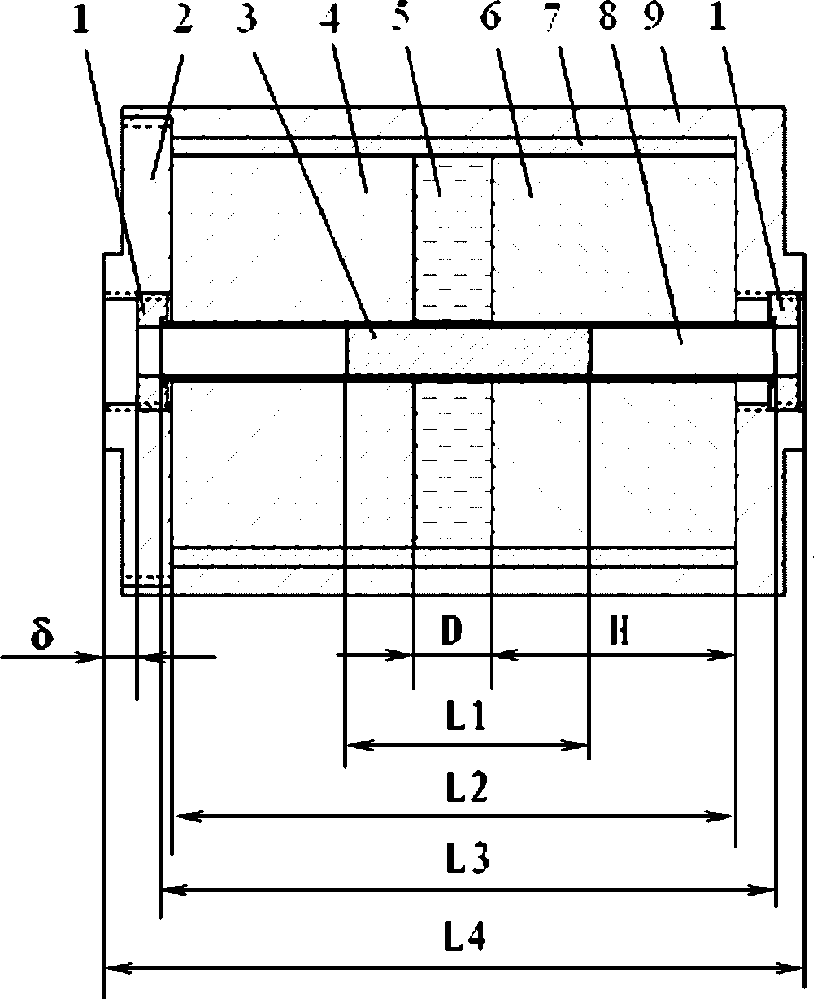

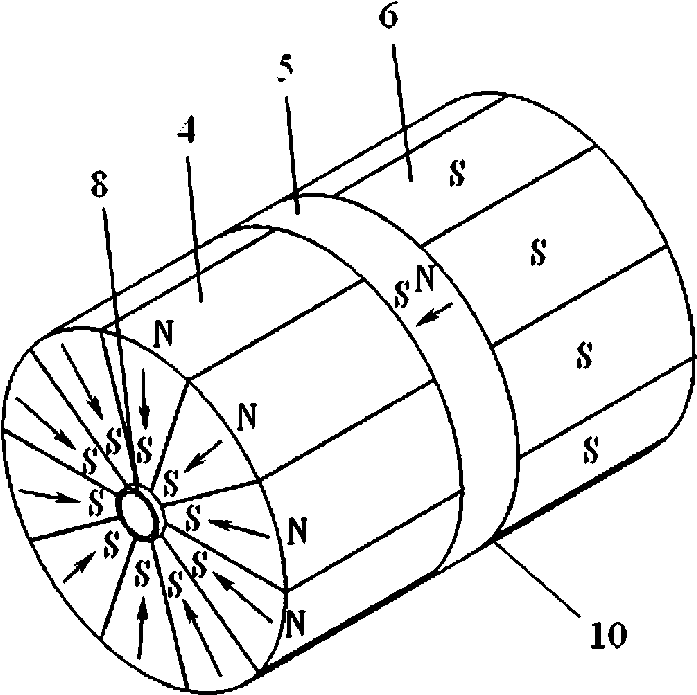

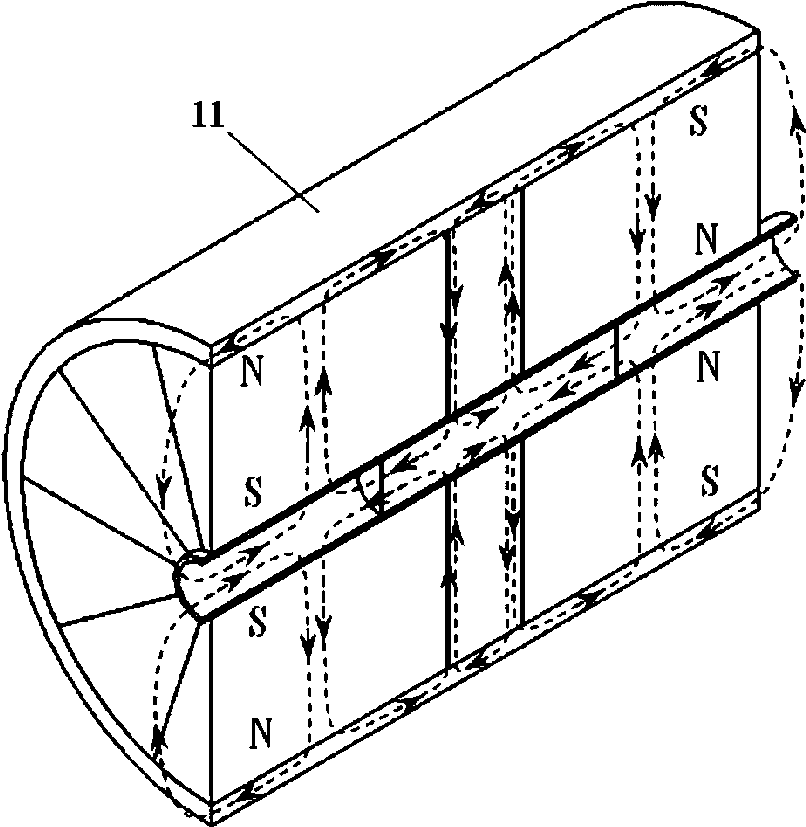

[0019] see Figures 1 to 3 , the Faraday rotator provided by the present invention consists of an adjusting plate 1, an end cap 2, a magnetic rotator 3, a first fan-shaped magnetic block 4, an intermediate magnetic block 5, a second fan-shaped magnetic block 6, a magnetic shielding sleeve 7, and a magnetic rotator Sleeve 8, housing 9, etc., in which the composite magnet 11 is composed of the first fan-shaped magnetic block 4, the second fan-shaped magnetic block 6, the middle magnetic block 5 and the magnetic shielding sleeve 7, and the adjusting piece 1, the end cover 2, the magnetic rotation optical The rod sleeve 8, the shell 9, etc. complete the adjustment and fixation of the relative position between the composite magnet 11 and the magnetic optical rotation rod 3. After the composite magnet 11 is placed in the shell 9, it is compressed with the end cover 2. There is a screw hole at the position coaxial with the inner hole of the composite magnet 11 on the shell 9 and the ...

Embodiment 2

[0025] The magnetic rotation rod sleeve (8) can be divided into 2 sections or 3 sections according to needs, so as to facilitate the fixing of the magnetic rotation rod (3).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com