Method and device for discharging liquid material

A liquid material and discharge device technology, which is applied in the direction of the device and coating of liquid coating on the surface, can solve the problem of uneven liquid material volume and achieve the effect of preventing uneven discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

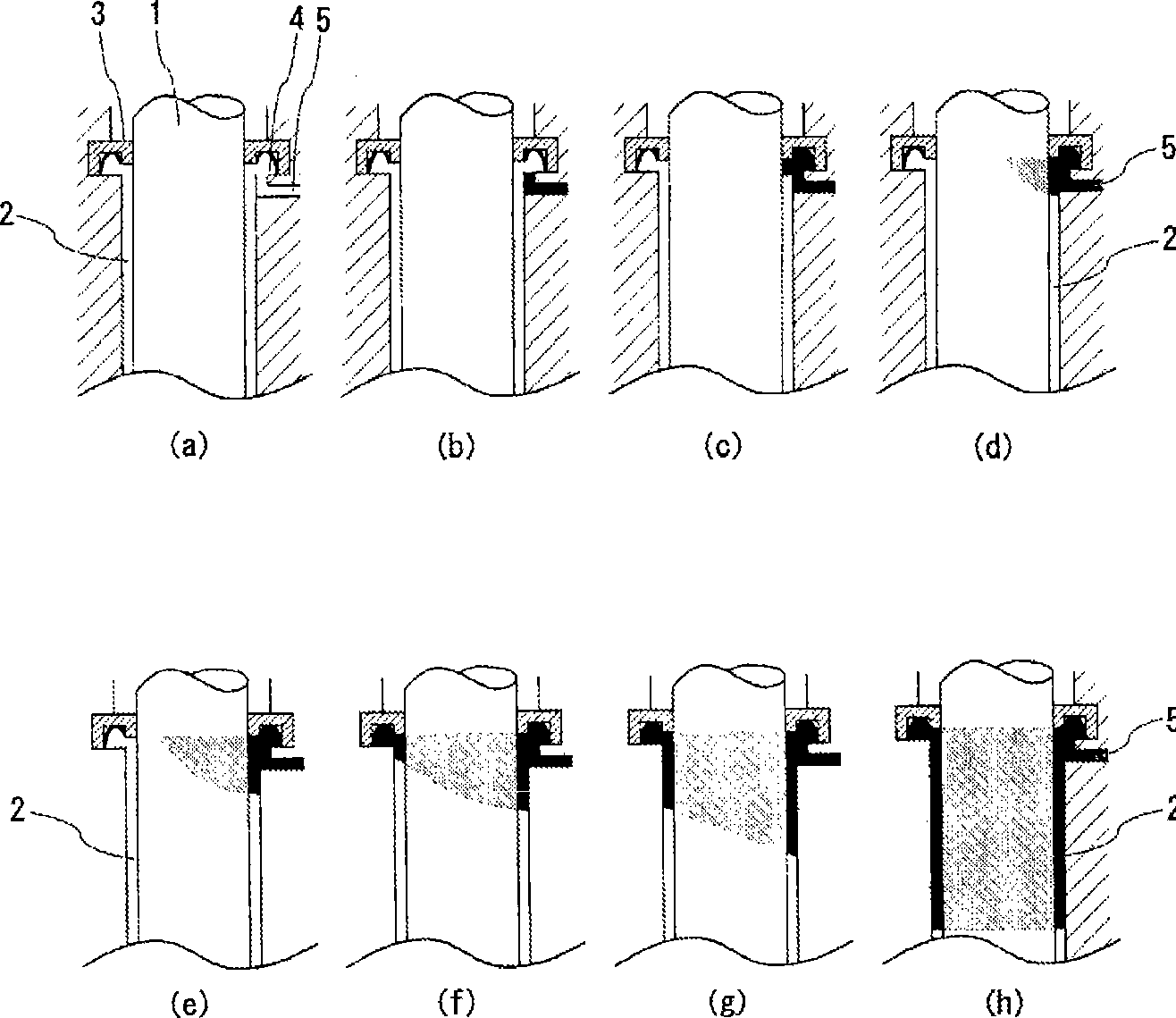

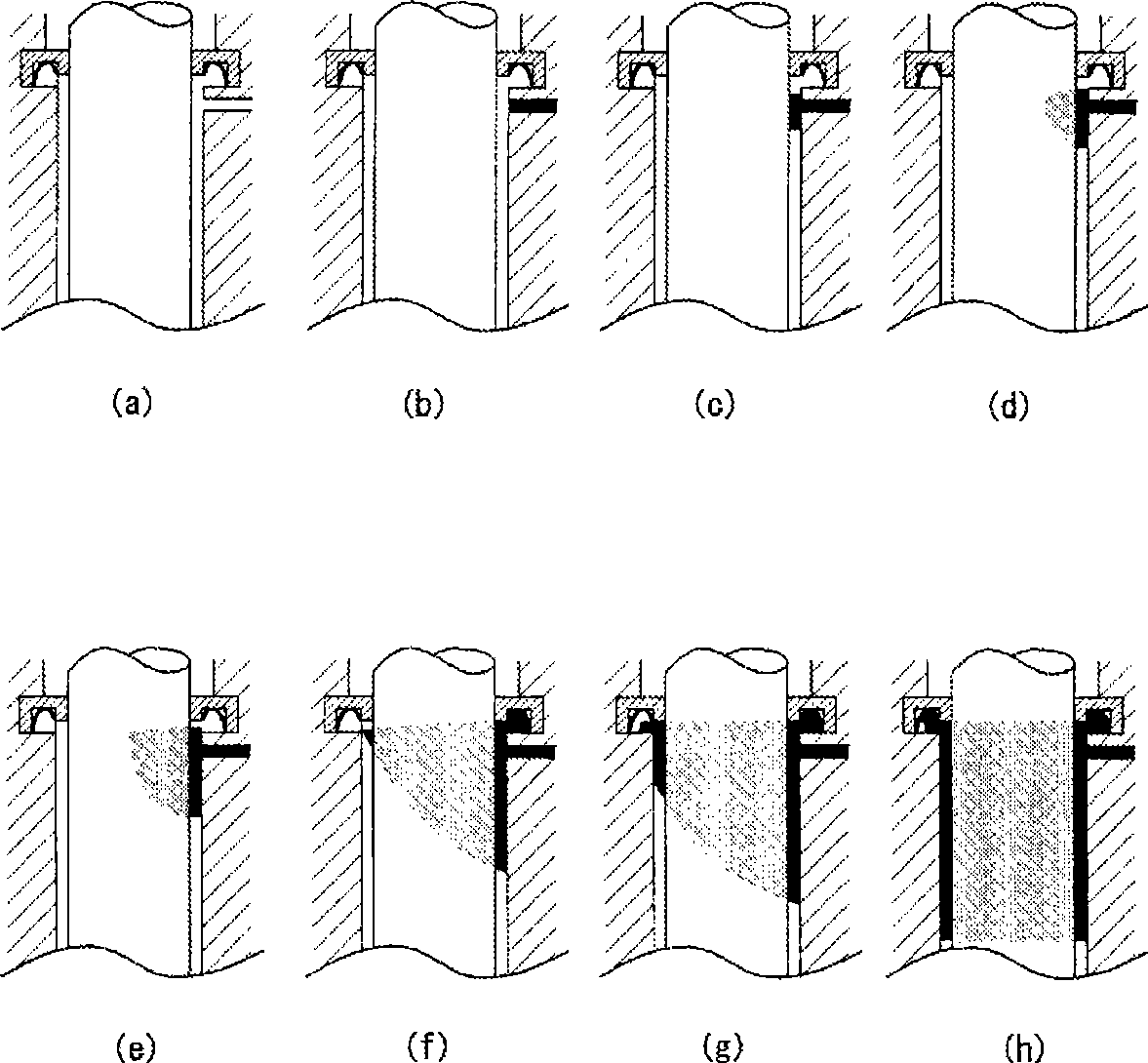

[0113] Figure 4 The disclosed device of this embodiment relates to a discharge device in which a liquid material is scattered and discharged using a nozzle 7 . More specifically, the device of this embodiment is a liquid material discharge device in which the liquid material is scattered and discharged from the tip of the nozzle 7 by the high-speed axial movement of the working shaft and the subsequent sudden stop.

[0114] structure

[0115] The main components of the device of this embodiment are: the flow path block 16 with the nozzle 7 inserted, the connection block 17 connecting the flow path block 16 and the air pressure block 18, and the structure that makes the working shaft 1 move. The driving source is the pneumatic block 18 and the working shaft 1 that reciprocates in the space provided inside each block.

[0116] The working shaft 1 is composed of a rod-shaped body shaft portion 21 and a flange 20 affixed to the rear end of the shaft body portion 21 . The worki...

Embodiment 2

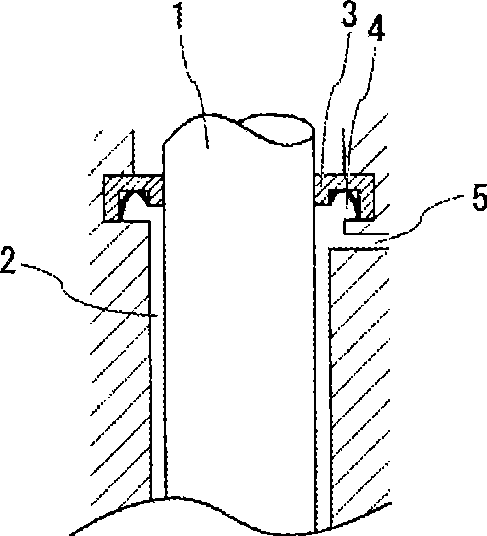

[0136] The device of this embodiment is an example suitable for use as a valve for liquid material discharge.

[0137] Figure 8 The device of the present embodiment shown is that the liquid material that is introduced into the valve and has been adjusted to a required pressure is discharged from the nozzle 7 while the working shaft 1 is separated from the valve seat 6, and the working shaft 1 is a discharge device that matches the valve seat 6 and stops the discharge from the nozzle 7.

[0138] structure

[0139] The device of this embodiment has a structure in which the pneumatic block 18 and the channel block 16 are directly connected without the connection block 17 .

[0140] The working shaft 1 having a rod-shaped shaft portion 21 and a flange 20 formed at the rear end of the shaft portion 21 is configured to extend between the blocks.

[0141] The flange 20 of the working shaft 1 is configured to be in close contact with the inner wall surface of the chamber 12 formed...

Embodiment 3

[0162] Figure 9 The disclosed device of this embodiment relates to a discharge device in which a liquid material is discharged from a nozzle 7 by rotating a working shaft 1 having a spiral flange at its tip.

[0163] structure

[0164] The main constituent elements of the device of this embodiment are a base plate 24, a top plate 25 provided at its upper end, a motor 50 provided at its upper end, a sealing block 23 provided at the center of the base plate 24, a bottom plate 24 lower end and It is connected to the flow channel block 16 arranged in the sealing block 23 and the working shaft 1 that rotates in the space provided inside each block.

[0165] The working shaft 1 is composed of a shaft body 21 and a front end 22 with a helical flange extending toward the shaft body 21 , and is arranged to pass through the sealing block 23 and extend toward the flow path block 16 . The shaft part 21 is connected to the rotating shaft of the motor 50 inserted through the through hole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com