Process and apparatus for building pneumatic tyres

A technology for pneumatic tires and equipment, applied in tires, applications, household appliances, etc., can solve the problems of equipment not working, unable to maintain conveyor belts, etc., and achieve the effect of preventing interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

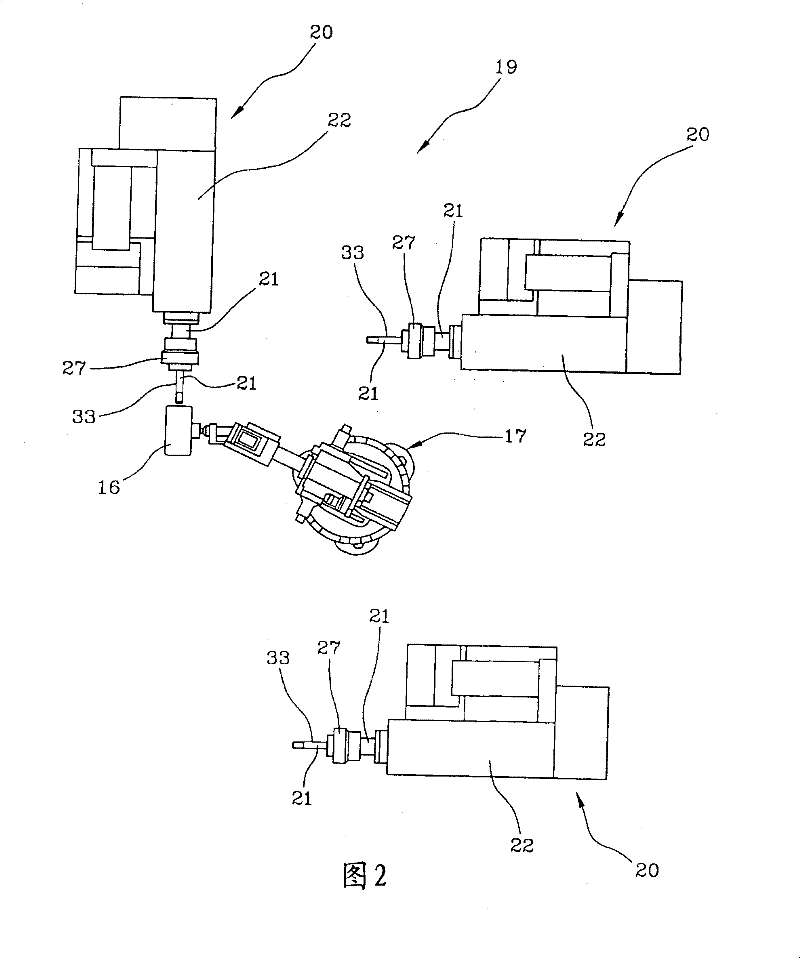

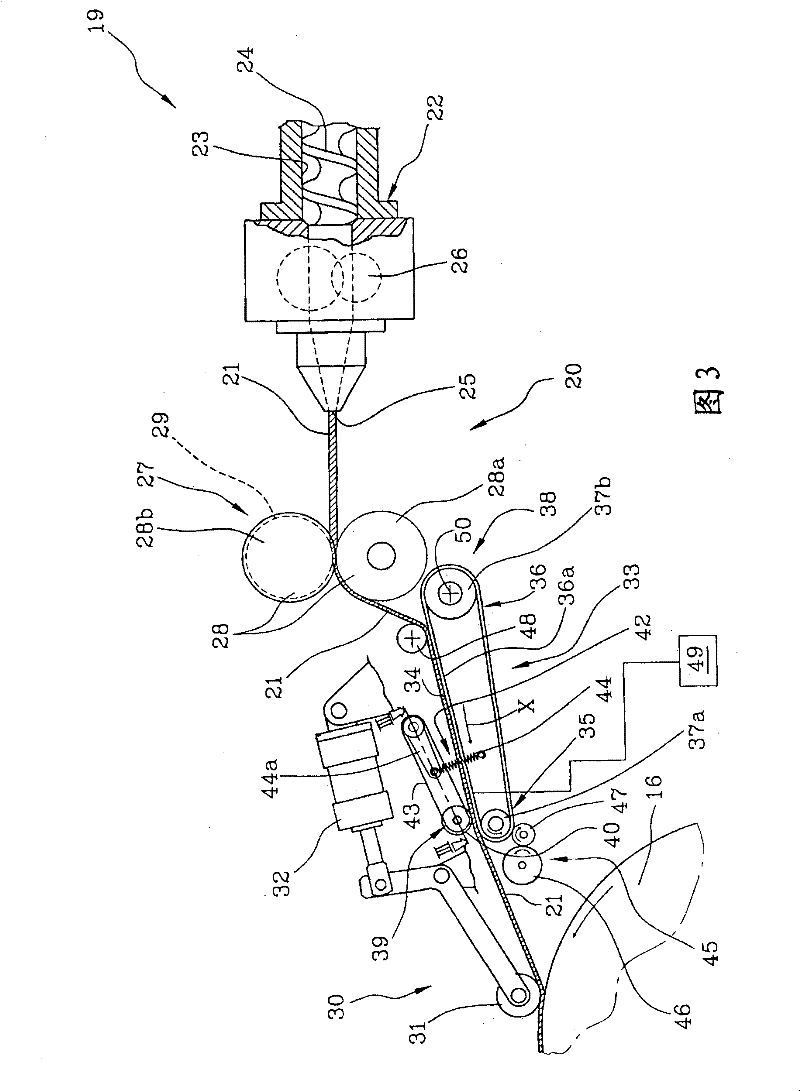

[0067] Referring to the drawings, a plant for the manufacture of tires is generally designated by the numeral 1, comprising a building plant 2 according to the invention.

[0068] Plant 1 is used to manufacture tires 3 (see Figure 5 ), the tire essentially comprises: at least one carcass ply 4, preferably internally coated with a layer of an air-impermeable elastomeric material or a so-called liner 5; two so-called "beads" ” 6, with their respective annular anchoring structures 7, where possible, the anchoring structures are connected to the elastomeric filler 7a and joined to the circumferential edge of the carcass ply 4; the belt structure 8, attached to the carcass along the radially outer position of the carcass 4; the tread strip 9, in the so-called crown region of the tire 3, which is laminated to the radially outer position of the belt structure 8; and the side walls 10, to which they are attached To laterally opposite positions on the carcass ply 4, the sidewalls are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com