Method and apparatus for robot calibrations with a calibrating device

A technology for calibrating devices and manipulators, applied in manipulators, using optical devices, program-controlled manipulators, etc., can solve the problems of time, cost complexity and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

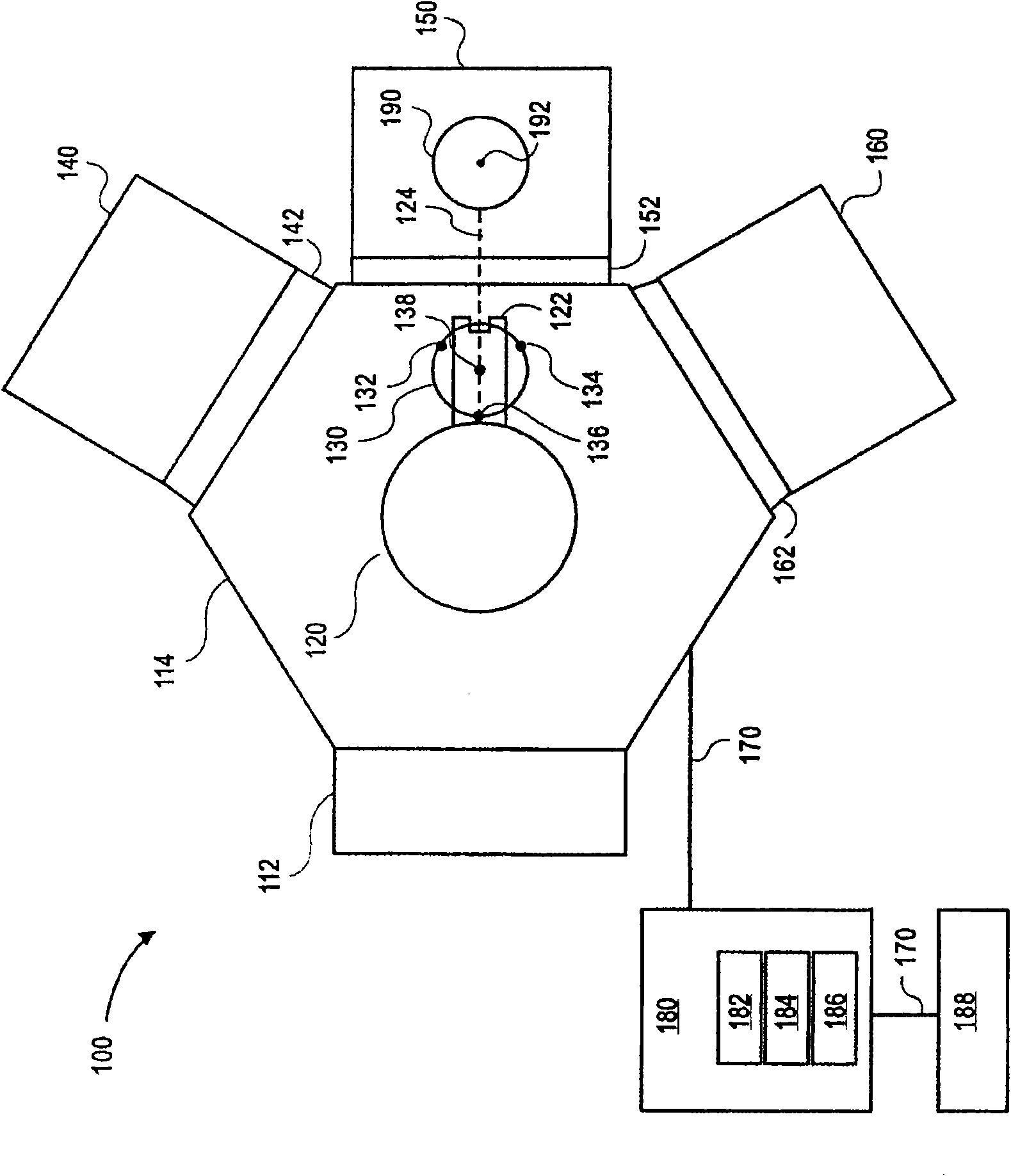

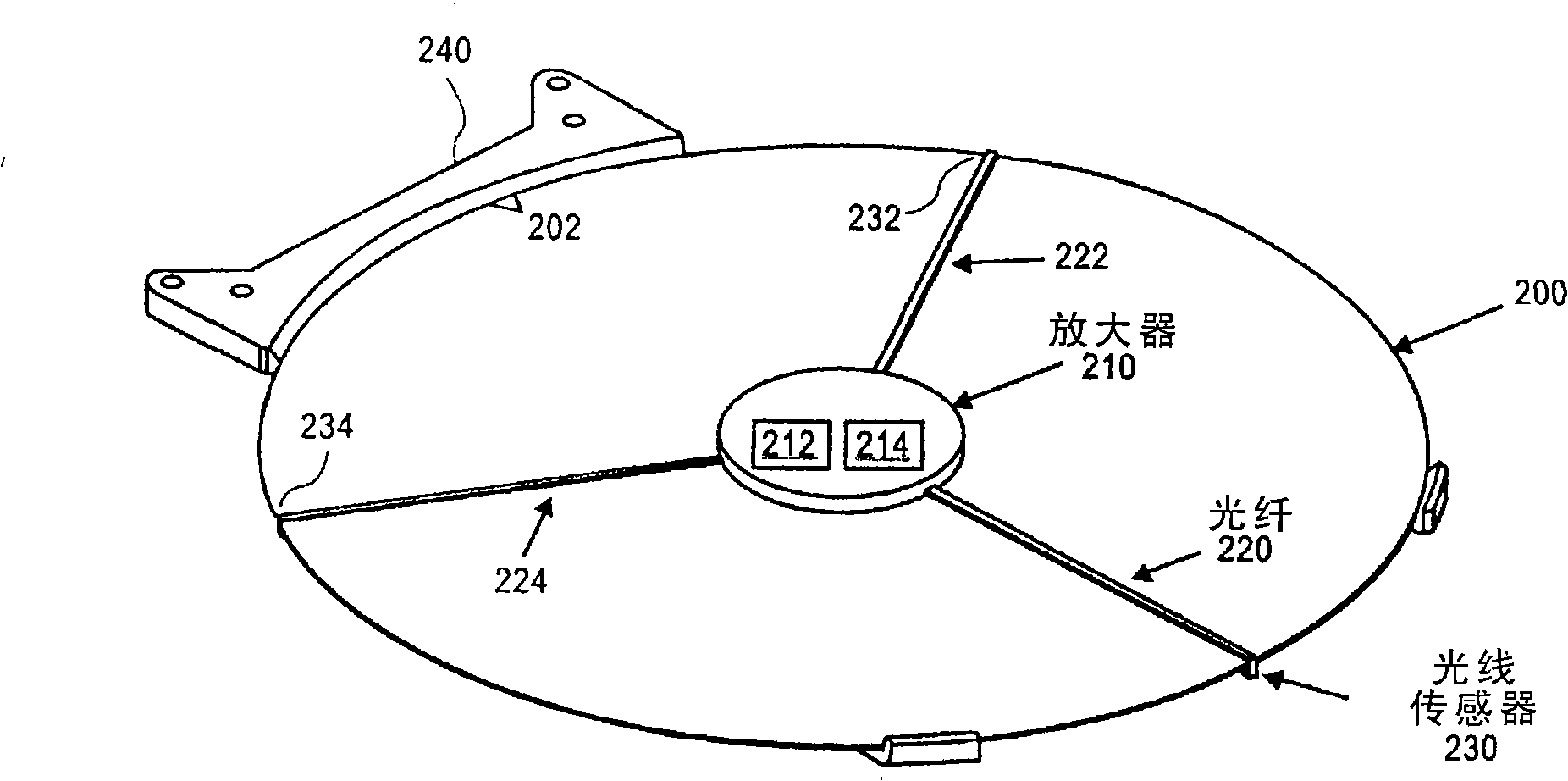

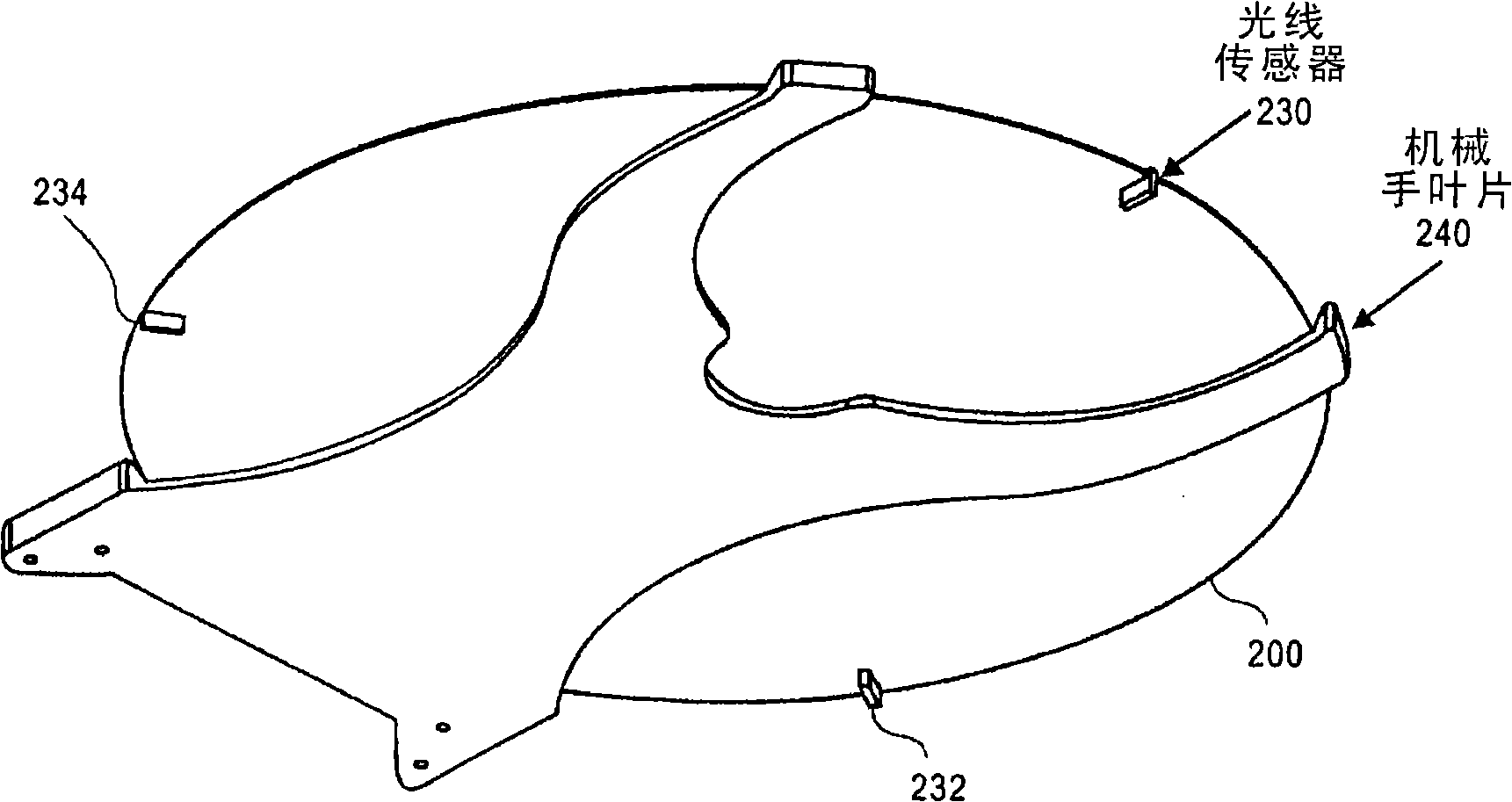

[0030] Described herein are methods and apparatus for performing calibration of manipulator elements. In one embodiment, a method for performing a manipulator calibration includes sensing a start point and an end point of a target with sensors positioned on a calibration device. The method further includes calculating a center of the object based on the start point and the end point of the object. The method further includes determining an offset between the center of the target and the manipulator blade positioned at the reference position. The method further includes calibrating the manipulator position based on the offset.

[0031] In another embodiment, a method for performing robot calibration includes moving a calibration device across a target (eg, a wafer chuck). The method then includes using a sensor positioned on the calibration device to measure the distance between a spot of light from the sensor and the perimeter of the target. Next, the method includes determ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com