Fins for serial fin type heat exchanger

A heat exchanger, serial fin technology, applied in the fin field of serial fin heat exchanger, can solve the problems of inability to form heat transfer effect turbulent layer, poor heat exchange effect, low heat transfer coefficient of fins, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

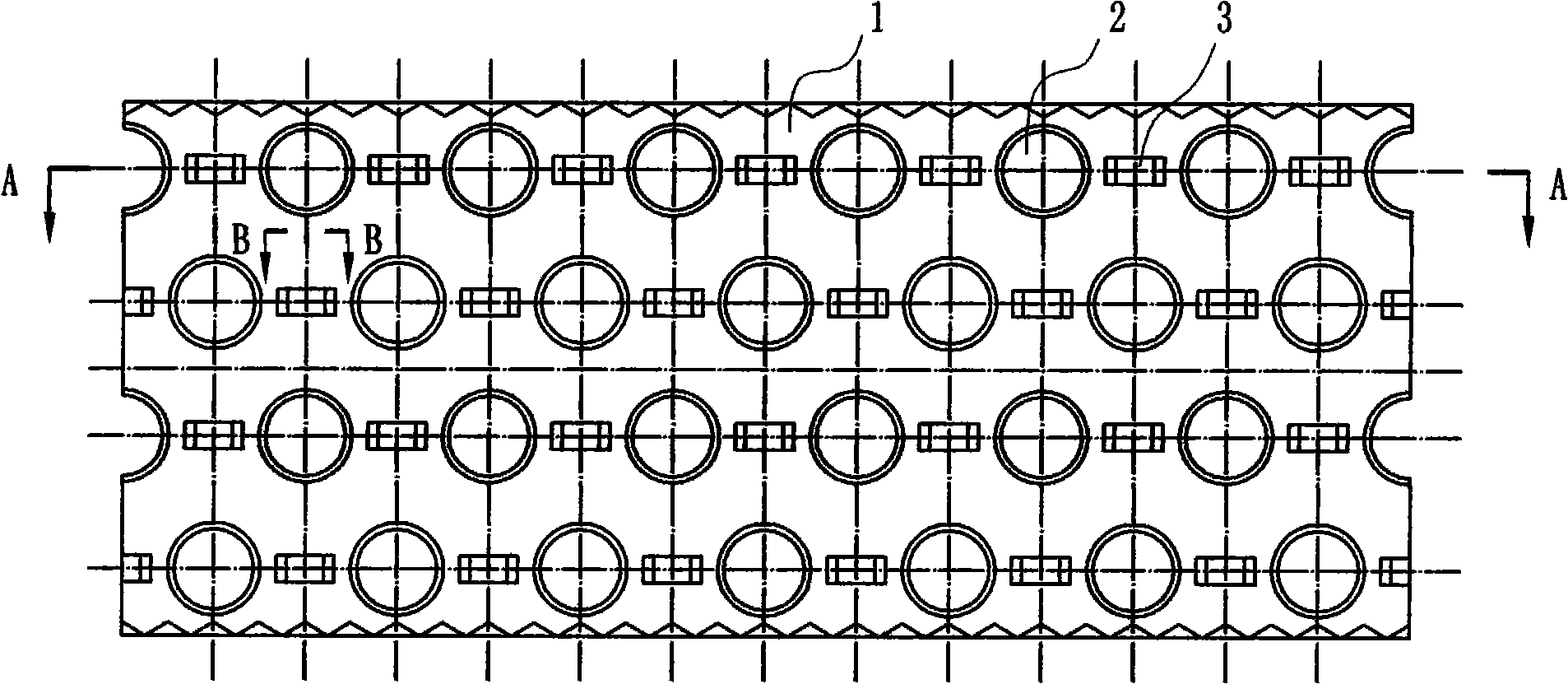

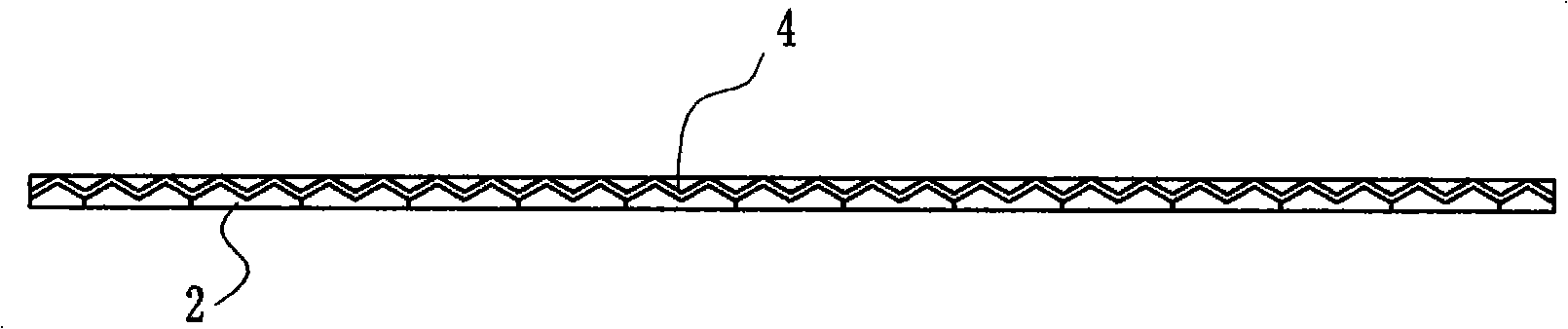

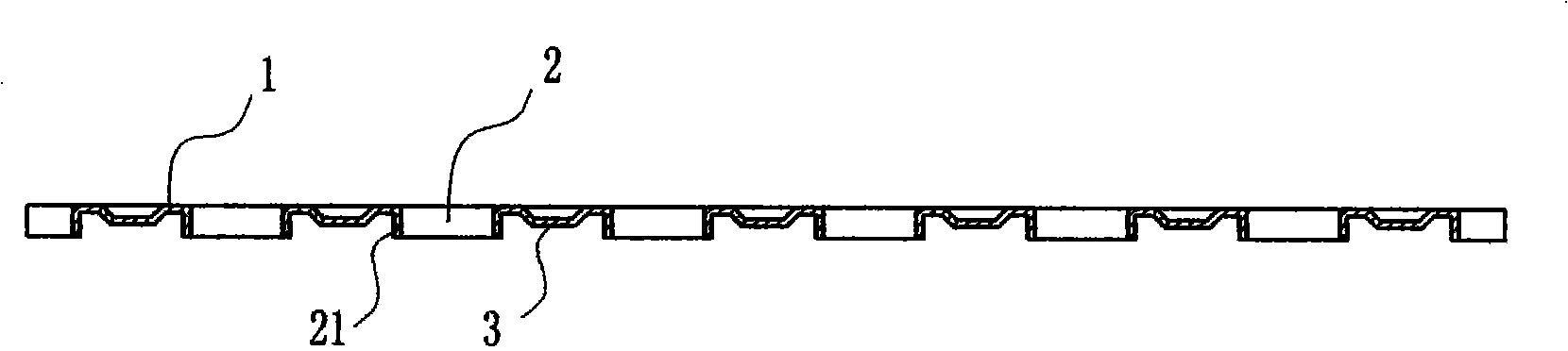

[0021] Such as figure 1 As shown, the fins of the serial-fin heat exchanger include a fin body 1, and the fin body is provided with tube holes 2 flanging to one side of the fin body 1, and the tube holes 2 between the tube holes The fin body 1 is provided with a first disturbance protrusion 3, and the side of the first disturbance protrusion 3 is provided with a cutout 31 communicating with both sides of the fin body 1. In this embodiment, each The first disturbance protrusion 3 has two cutouts 31, and the cutouts 31 are respectively arranged in the flow direction of the medium, which reduces the generation of vortex turbulence clusters.

[0022] Such as image 3 As shown, the first disturbance protrusion 3 faces the direction of the flanging of the tube hole 2, and the height of the first disturbance protrusion 3 is smaller than the height of the tube hole flanging 21, which further reduces the resistance of the medium to pass through, thereby improving the fin heat transf...

Embodiment 2

[0025] This embodiment is basically the same as Embodiment 1, except that a second disturbance protrusion 5 is provided on the periphery of the tube hole 2, and the side surface of the second disturbance protrusion 5 is provided with a 1 cutouts 51 on both sides.

[0026] The second disturbing protrusion 5 faces the direction of the flange of the tube hole 2 , and the height of the second disturbing protrusion 5 is smaller than the height of the flange 21 of the tube hole.

[0027] In this embodiment, the second disturbance protrusions 5 are arc-shaped, and are evenly distributed around the tube hole 2 .

[0028] On the one hand, this embodiment enhances the strength of the tube holes, prevents the fins from being damaged during the process of connecting the fins in series, and at the same time further enhances the generation of medium turbulent flow, so that the heat exchange efficiency of the fins is greatly improved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com